Three Mindsets of Product Development

© 2023 Nilesh D Kulkarni, Saurav Bansal, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

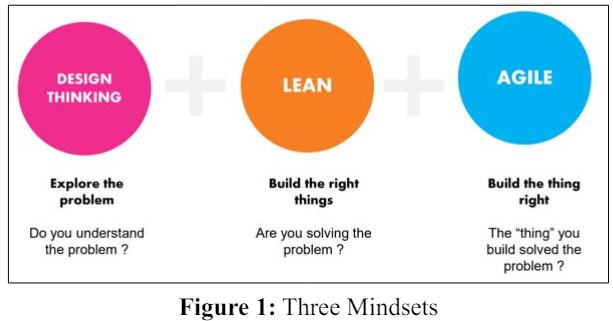

The paper "Three Mindsets of Product Development" presents an analysis of three pivotal approaches in product development: Design Thinking, Lean, and Agile. It explores how Design Thinking focuses on understanding user needs for innovative solutions, Lean emphasizes value creation with minimal resources and continuous improvement, and Agile advocates for adaptability and prioritization in response to change. The narrative is enriched with a story about Erik, a restaurant customer, to illustrate the practical application of these mindsets in enhancing customer value, process efficiency, and problem prioritization.

Introduction

Design Thinking: Design thinking is an iterative process in which you seek to understand your users, challenge assumptions, redefine problems and create innovative solutions which you can prototype and test [1]. Simply put ?Explore the problem?.

Lean: Lean is a way of thinking about creating needed value with fewer resources and less waste. And lean is a practice consisting of continuous experimentation to achieve perfect value with zero waste. Lean thinking and practice occur together [2]. Simply put ?Build the right things?.

Agile: Agile is the ability to create and respond to change. It is a way of dealing with, and ultimately succeeding in, an uncertain and turbulent environment. The authors of the Agile Manifesto chose ?Agile? as the label for this whole idea because that word represented the adaptiveness and response to change which was so important to their approach [3,4]. Simply put ?Build the thing right?.

Business Context

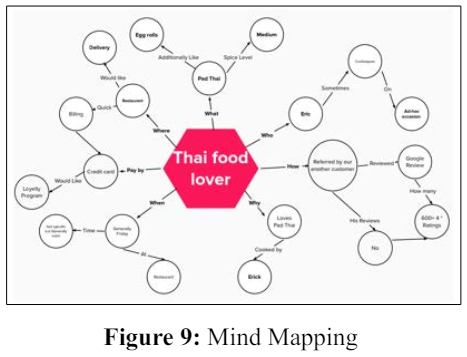

?A picture is worth a thousand words?, The below picture tells many different keywords to construct the story of the person shown in the picture.

To put it in the context, let see Erik’s story - Eric like Thai food and is a frequent visitor to a Thai restaurant named ?Simple Thai?. Every Friday of the week he visits Simple Thai to eat his favorite ?Pad Thai? with ?Egg Rolls? at lunch. On this Friday, Eric came to the restaurant, Steve who is a waiter at the restaurant welcome him and seated him at table #12 by the window and handed him with the menu card. Eric looked at the menu, but he knew what is going to order. He called Steve and ordered ?Pad Thai? with ?Egg Rolls?.

Steve took the order and punch it in the system, Eric a best Thai cook, is a watching all the incoming tickets in the kitchen received the order for table #12.

It took little over 15 min for Erik to finish the table #12 order, and he place the order for Steve to pick up and serve it. In less than a minute after Erik rang the ready bell, Steve took the order and served on Eric’s table. Eric started with the egg rolls and then immediately switch to his favorite Pad Thai, since he had to leave early and sometimes it takes time to get the bill, he waved Steve and asked for the check.

Steve immediately went to the POS and printed the bill; he placed the bill on Eric’s table. Eric pulled his credit card and placed it on the bill. Steve took the card and bill and handed it over to Nicole to process the payment. John ran the card through the machine and handed receipt over to Steve, Steve took the receipt and placed it on table# 12. By this time Brad finished his food and by saying thanks for the great meal he left the restaurant.

Identifying Value

A clear understanding of what customers want and what matter the most. In the example of Erik, the value for the Erik is not ?cooking time? or ?payment method? or ?price? or ?table placement?, those are important but more important is ?Tasty Pad Thai?, since Erik wants to visit the restaurant to ?eat his favorite Pad Thai?.

The question one should ask to determine the value ?Will Eric be happy customer if he gets everything but a tasty ?Pad Thai?? and if the answer is ?No? then you found the value.

Knowing the value is the first step in Design thinking - problem exploration. As quoted by Jeff Bezos ?We see our customers as invited guests to a party, and we are the hosts. It's our job every day to make every important aspect of the customer experience a little bit better. Start with the customer and work backward.?

Lean

Lean is a way of thinking about creating needed value with fewer resources and less waste. And lean is a practice consisting of continuous experimentation to achieve perfect value with zero waste. Lean thinking and practice occur together.

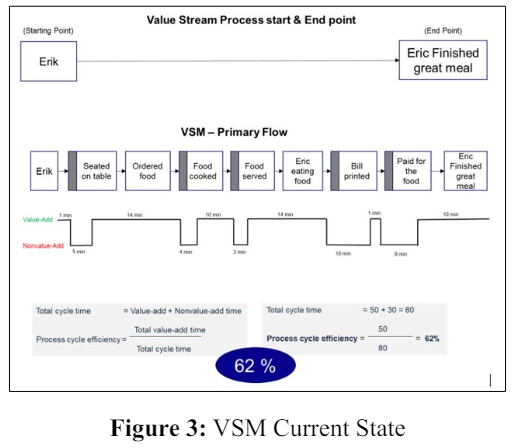

Lean Tool: Value Stream Mapping - Current State

Value stream mapping is a lean manufacturing technique that has been adopted by Agile methods. This method helps illustrate the flow of information/material within the process and help identify the waste. It is a fundamental tool used in continuous improvement to identify and eliminate waste. Toyota developed the tool ? which it calls a material and information flow diagram ? and it is a critical part of the Toyota Production System [5].

Value Stream Mapping Steps

1.Identify the product or service you are analyzing

2.Create current state value stream map (steps, delays,information flow etc.)

3.Review and find delays, waste and constraints

4.Create future state value map by optimizing flow and removing waster

5.Continuously revisit the process to tune and optimize

Erik’s Value Stream Map - Current State

The first step to identify Value stream is to plot the steps, and identify value-added and non-value-added steps to calculate the current process cycle efficiency = Total Value-add time / Total cycle time.

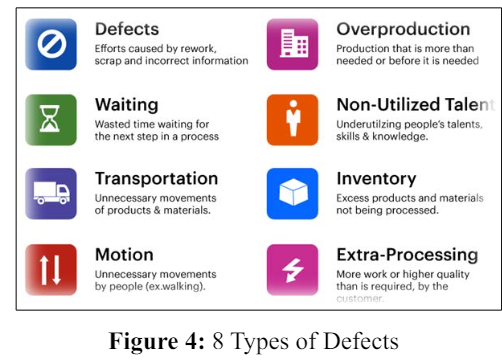

Lean Tool: Identify Type of Waste

Waste is any step or action in a process that is not required to complete a process (called ?Non-Value-Adding?) successfully. When Waste is removed, only the steps that are required (called ?Value-Adding?) to deliver a satisfactory product or service to the customer remain in the process [6].

For each non-value-added step, we need to identify the type of waste using a method called ?DOWNTIME?

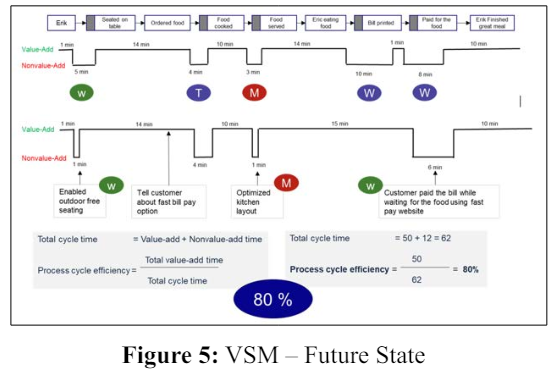

Lean Tool: Value Stream Mapping - Future State

The next step is to identify the waste ?Problem? that can be solved with changing the process, layout or may be use of technology. Apply the right problem-solving technique to each of the waste by applying Lean ?are you solving the right problem? philosophy.

Once the solution is identified and applied to the process, calculate the new process cycle efficiency to compare with the previous efficiency. This technique will not only help improve the process cycle time but intern enforce the value creation from the customer ?Eric?.

Agile Tool: Prioritization

While solving problem is important to create value, more important is to prioritize the problems to solve. In this context, there are multiple problems to solve and solving them iteratively in a correct sequence will help capitalize on the value creating faster. Couple of techniques that can help prioritization.

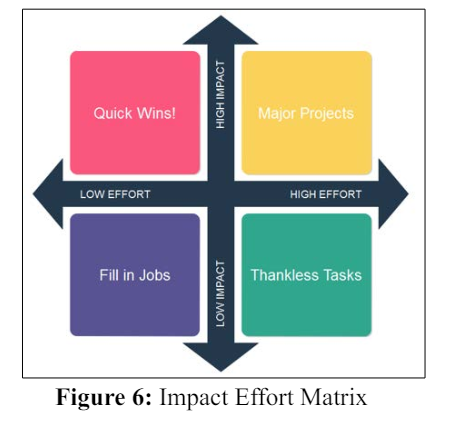

Agile Tool: Impact Effort Matrix

The Impact Effort Matrix is a simple, visual decision-making tool to help teams prioritize their efforts based on the likely effort vs end impact [7].

By identifying the Impact and Effort associated with solving each of the problem identified as a waste, will help categorize each unit of work in the quadrans shown on the image. This will allow easy prioritization in four categories:

1.Quick wins: low effort and high impact.

2.Major projects: high effort and high impact.

3.Fill in jobs: low effort and low impact.

4.Thankless tasks: high effort and low impact.

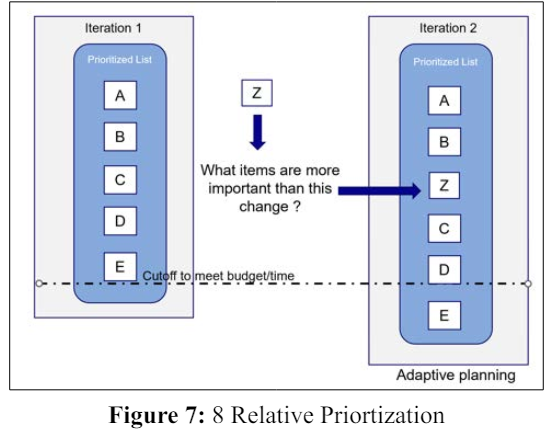

Agile Tool: Relative Prioritization Method

Relative prioritization provides a framework for deciding which changes are going to have more impact. This technique can further sequence the priority within the quick wins or major projects. The technique involves asking a question? What items are more important that this?? as shown I figure 7

Design Thinking

Design thinking is an iterative process in which you seek to understand your users, challenge assumptions, redefine problems and create innovative solutions which you can prototype and test

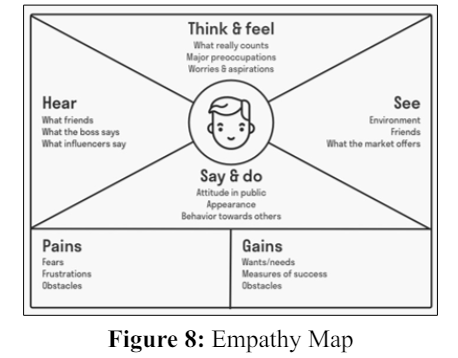

Design Thinking - Empathy Map

An empathy map is a simple, easy-to-digest visual that captures knowledge about a user’s behaviors and attitudes and empathy map is the most useful tool at the beginning of the design process.

Empathy maps are useful in design thinking and product development. By delving into the user's thoughts, feelings, words, and actions, these maps offer a holistic view of the user's experience. Key Benefits of Empathy Maps:

- Benefit#1. Empathy mapping is an easy and quick task to complete

- Benefit#2. The visualization process allows involving many people.

- Benefit#3. It helps creators think beyond their expectations and understand that their ideal product vision may differ from the clients’ point of view.

- Benefit#4. Using empathy maps for better UX design goes beyond the research stage.

- Benefit #5. Using the data from field survey, empathy maps create a life-like image of your marketing persona rather than subjective insights

- Benefit #6. These tools are universal and can be applied to any domain, industry or type of business [8].

Design Thinking Tool: Mind Map

A mind map is a graphical way to represent ideas and concepts. It is a visual thinking tool that helps structuring information, helping you to better analyze, comprehend, synthesize, recall and generate new ideas.

How to Draw a Mind Map

•Start in the middle of a blank page, writing or drawing the idea you intend to develop..

•Develop the related subtopics around this central topic, connecting each of them to the center with a line.

•Repeat the same process for the subtopics, generating lower- level subtopics as you see fit, connecting each of those to the corresponding subtopic.

Conclusion

The paper discusses three key approaches: Design Thinking, Lean, and Agile. Design Thinking emphasizes understanding users and creating innovative solutions. Lean focuses on creating value with minimal resources and waste, incorporating continuous improvement and waste elimination techniques like Value Stream Mapping. Agile prioritizes adaptability and responding to change, using tools like the Impact Effort Matrix for prioritizing problems. The document illustrates these concepts with a story about Erik, and hhighlights the synergistic potential when these approaches are combined, as seen in the case study of Erik's Thai restaurant project. It cconcludes by emphasizing the holistic benefits these mindsets offer in enhancing customer satisfaction, optimizing resources, and navigating complex, evolving market demands. This integrated approach is vital for modern product development's success within small-large organization.

References

1.Dam R, Siang T (2022) What is Design Thinking and Why Is It So Popular. Interaction Design Foundation https://www. interaction-design.org/literature/article/what-is-design- thinking-and-why-is-it-so-popular.

2.What is Lean. Lean Enterprise Institute https://www.lean. org/explore-lean/what-is-lean/.

3.Kent Beck, Mike Beedle, Arie Van Bennekum, Steve Mellor, Jon Kern, et al. (2023) Agile Manifesto. Agile Alliance https:// www.agilealliance.org/agile101/the-agile-manifesto/.

4.Fowler M (2006) Agile Story. MartinFowler.com https:// martinfowler.com/articles/agileStory.html.

5.Value Stream Mapping. Lean Enterprise Institute https://www. lean.org/lexicon-terms/value-stream-mapping/.

6.Skhmot N (2017) The 8 Wastes of Lean. The Lean Way Blog https://theleanway.net/The-8-Wastes-of-Lean.

7.(2022) How to Use the Impact Effort Matrix to Prioritize Projects. Six Sigma Daily https://www.sixsigmadaily.com/how-to-use-the-impact- effort-matrix.

8.Gresev N (2019) Benefits Of Using Empathy Maps In UX Design. Justcoded https://justcoded.com/blog/benefits-of- using-empathy-maps-in-ux-design/.