The Future of 3D Printing in Prototype Development: Minimizing Prototype Costs and Decreasing Validation Timelines

© 2023 Sakthivel Rasu, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

ABSTRACT

This paper relates to a critical overview of how 3D printing is transforming the development process of prototypes with the help of its capacity to reduce costs and lessen the pre-validation time that is required by production.

Unlike traditional manufacturing, 3D printing at this time allows for faster iterations, eradication of tooling costs, and better material usage.

These are the main factors that arise: material selection, process optimization, and rapid prototyping advantages of the industries dealing with automotive, aerospace, healthcare, and consumer electronics.

Some future trends that will shape 3D printing technology include advanced materials, further automation, and integration of AI, among other emerging technologies that eventually may affect product design and validation processes.

It finally concludes by discussing the long term benefits involved in the adoption of 3D printing for prototype development regarding increased innovation and cost efficiency.

Key Points

- Cost Reduction through Material Efficiency: 3D printing minimizes material waste due to the additive manufacturing process that uses only what is needed. This is particularly helpful for industries such as aerospace, which use so many high-cost materials like titanium.

- Elimination of Tooling Costs: Traditional prototyping requires tooling, which is expensive, for every 3D printing removes this step altogether. This gives the ability for more rapid iterations at a much lower cost.

- Labor Cost Reduction through Automation: 3D printing reduces manual interference in the production of the The majority of the work is dealt with and handled through automated systems, which greatly minimizes human errors and saves labor costs.

- Accelerated Prototyping and Validation: This is because 3-D printing allows companies to try out and make changes in designs much faster to enable rapid iterations. The result is shorter validation timelines, faster time-to-market, and a dramatic reduction in the costs associated with certification and testing.

- Cross-Industry Applications: 3D printing has found extensive applications in industries such as aerospace, automotive, healthcare, and consumer electronics. Each of these sectors enjoys some advantage: the speed at which prototyping is done, cost reductions, or improvements in design validations.

- Future Trends: Material development, automation, AI integration, and distributed manufacturing are the factors that will continue to make 3D printing an even more powerful tool for prototype development.

Introduction

It is one of the most intensive parts of a product development cycle, which validates the design, functionality, and manufacturability of a product before its mass production. Traditionally, this process has been expensive and time consuming.

That is where 3D printing, also called additive manufacturing has redefined how companies approach prototype development. Moving to 3D printing for prototyping has allowed companies to iterate faster, reduce costs, and considerably cut down on product validation time.

This article identifies that 3D printing is rapidly gaining popularity for prototype development owing to its cost saving capabilities and accelerating the time taken for validation.

Further, we delve into areas where 3D printing applications are utilized industrially and determine some future trends that are going to continue to reinforce the use of 3D printing in prototype development.

The Role of 3D Printing in Cost Minimization

Reduction of Material Waste

One of the greatest salient benefits of 3D printing over traditional manufacturing techniques is that it reduces waste dramatically. Most traditional methods involve subtractive techniques, such as CNC machining or injection molding, where a larger block of material is used and the excess has to be removed. This can be very wasteful and expensive when working with metals, composites, or specialty plastics.

Conversely, 3D printing is a process of creating objects by adding layers on top of one another, using only the amount of material necessary in the process. A reduction of waste leads to direct cost savings for industries like aerospace, with high-performance materials used extensively, such as titanium and carbon fiber.

A good example of this is in the fabrication of aircraft components using 3D printing. Companies such as Boeing, for instance, have been able to save up to 90% of the input material when additive manufacturing techniques are adopted instead of traditional methods.

This equates to millions of dollars in savings on prototype development costs. What is most important to note in this regard is that this can be scaled up and considered appropriate for any industry where the material cost would be the higher fraction of the prototyping cost involved.

Elimination of Tooling Costs

One factor that is particularly inhibiting in traditional prototype development is tooling costs: the molds, dies, and other components of tooling are expensive and time consuming to make, especially when complex geometries or low volumes are involved.

As a rule, every iterative step of a design requires modifications or even an entirely new set of tooling, which prolongs the development time and inflates the cost.

3D printing totally avoids the necessity for tooling. As the design is made on a digital platform and directly fed to a 3D printer, companies can make prototypes without having to bear the cost and delays pertaining to tooling. This is especially welcome in industries like automotive and consumer electronics where multiple design iterations are necessary before arriving at the final validation.

For instance, Ford Motor Company has used 3D printing to prototype engine parts and has saved as much as 70 percent of what was usually meant for tooling. This has helped the company hasten product development through increased testing and refinement of designs with no extra costs in tooling.

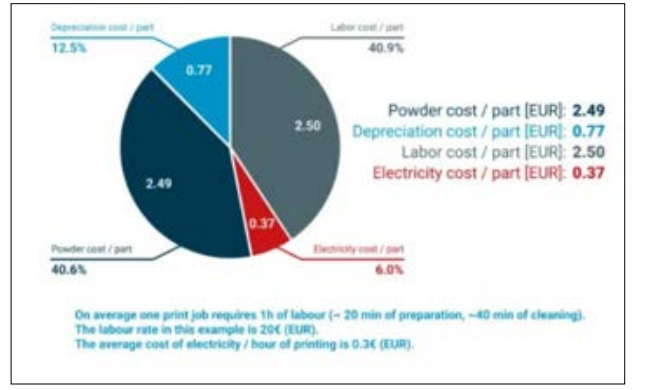

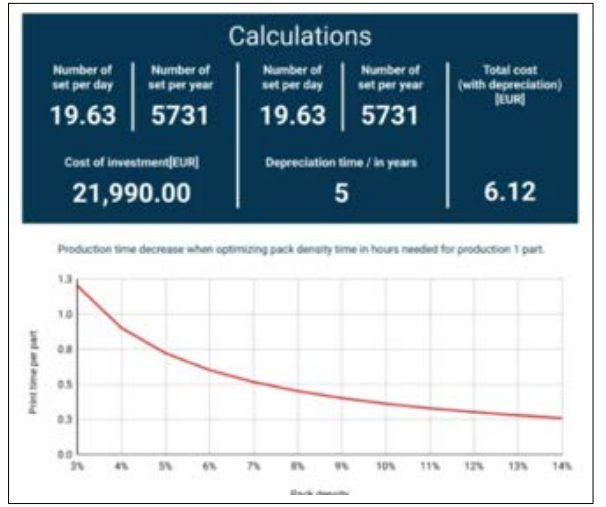

Optimizing Labor Costs

If there is one area where 3D printing brings significant savings, it is in the reduction of labor-intensive processes. Traditional prototyping often involves portions of manual work, each stage succeeding the other-machining, assembly, and post processing. Each step provides an avenue for human fallibility, which escalates the development timeline even more and increases costs due to rework or adjustment.

As soon as the CAD file is completed through 3D printing, the process is mainly automated. This means that the machine tends to operate with the least human intervention, and reduced need for skilled labor at the initial stages of development in a prototype.

Additionally, 3D printing allows the fabrication of complex geometries within a single build, often dispensing with assembly altogether. This automation results in a very smooth process, which reduces labor costs while minimizing errors.

In industries that use highly customized and complex medical devices, such as in healthcare, the labor cost has been drastically reduced by 3D printing.

Companies producing orthopedic implants, for example, shifted from multi-step hand operations to fully automatic 3D printing of these devices. This brought cost and production time down drastically.

Rapid Iteration and Concurrent Testing

The speed at which designs can be iterated and tested is a very important cost reduction factor in prototype development. Traditional methods, which usually have several steps of tooling acquisition, material acquisition, and labor-based production, limit how many design iterations can be tested in a given timeframe, resulting in longer validation periods and slower time-to-market.

3D printing significantly reduces the time taken for each design iteration. Having printed the first prototype, it's then relatively quick and easy to make modifications within the CAD software.

A newer version can be printed within hours. With the ability to iterate rapidly, multiple designs can be tested simultaneously, reducing the validation and final approval time.

A key manifestation of this might be the use of 3D printing in consumer electronics. Companies such as Apple have employed rapid prototyping to design and test multiple iterations of a product component case and internal structures at a pace so much quicker than was possible using traditional methods.

Such agility reduces development costs but also enables the companies to respond with rapid releases to changing market needs and technology advancement.

|

Factor |

3D Printing |

Traditional Prototyping |

|

Material Waste |

Low |

High |

|

Tooling Costs |

None |

High |

|

Labor |

Automated |

Manual |

|

Speed |

Fast |

Slow |

|

Overall Cost |

Lower |

Higher |

Decreasing Validation Timelines with 3D Printing

Early-Stage Validation Through Functional Prototypes

Perhaps one of the biggest advantages that 3D printing provides in prototype development is the fact that it can make functional prototypes. These are not just aesthetic models but are often fully workable and can be tested with natural conditions.

Therefore, early stage validation may be availed with valuable insight into the performance of the product for necessary adjustments before the commencement of full-scale production.

It has been used in the making of functional prototypes of surgical and implantable instrumentation that surgeons can clinically test. This level of validation would not be possible with traditional prototyping methods due to the time and cost involved; thus, potential issues can make earlier detection, leading to faster approval times.

Simultaneous Prototyping and Testing

Another major time saving aspect of 3D printing is the ability to prototype and test simultaneously. While with the traditional approach, each iteration needs to be completed and tested before a new prototype is fabricated, this new technique will allow several versions of your prototype to be printed out simultaneously.

This parallel testing methodology greatly shortens the validation timeline because different designs can be tested side by side.

It is a capability of much value in the automotive segment, where one needs to test multiple variations of components related to parts of engines to complete aerodynamics.

Printing several prototypes will reduce the overall time taken for testing by several weeks, even months.

Integration with Digital Simulation Tools

3D printing is being increasingly used to help reduce validation timelines, especially in concert with digital simulation tools. In fact, the latest CAD packages have functionalities that can virtually simulate prototype testings for stress-strain and thermal variations.

Such simulations can take place even before the physical prototype is printed out, thus ensuring that only the most viable among the designs move forward in the development life cycle.

This can be very effective in industries with rather long and labor-intensive processes for the validation of parts through a multidisciplinary approach using digital simulation and rapid prototyping.

Such rapid techniques have enabled firms like SpaceX to shave months off their validation timelines by identifying potential issues early in the simulation phase and rapid iteration through 3D printing.

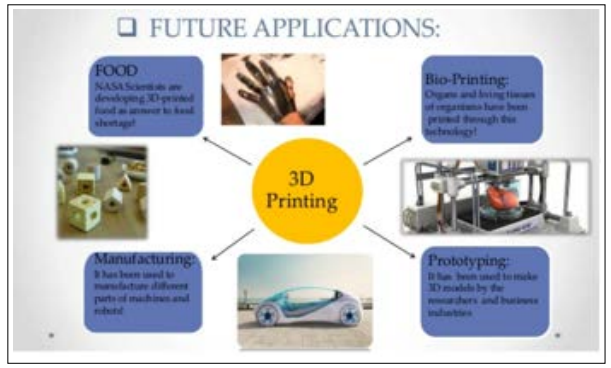

Industry-Specific Applications of 3D Printing in Prototype

Development Aerospace

One of the earliest adopters of 3D printing technology, especially for prototyping high-performance parts, is the aerospace industry. To this end, the capability to manufacture lightweight yet strong components has allowed companies in this industry to create prototypes for everything from engine components to wing structures.

Such rapid iteration of these designs could allow aerospace manufacturers to do what traditional methods have never quite achieved: validate the functionality of critical parts.

Further, 3D printing was instrumental in the manufacturing of low volume but highly specialized parts, which helped reduce production costs and shave off some time in making prototypes.

For example, Lockheed Martin has already incorporated 3D printing into its development workflow, which reduced validation timelines by up to 50%.

Automotive

3D printing is becoming both a prototyping and production method in the automotive industry. Prototyping via 3D printing allows automakers to test newer designs faster, including those for very complex parts such as engine blocks, exhaust systems, and interior features.

The ability for quick iteration and simultaneous testing of many variations has become a game changer for automotive engineers.

The result has been that both BMW and Volkswagen can boast dramatic cuts in development times, producing and validating prototypes in days rather than weeks or months.

Healthcare

The manufacturing of medical devices, from prosthetics and implants to surgical instruments, has adopted 3D printing in prototyping. 3D printing would be ideal for making prototypes, offering precision and value for customization. These kinds of functional prototype tests in clinical settings lead to quicker approval and commercialization.

Moreover, 3D printing facilitates the creation of anatomical models for pre-surgical planning and hence improves patient outcomes by reducing the regulatory approval time of a device.

Consumer Electronics

Companies are increasingly manufacturing consumer electronics through 3D printing for the rapid prototyping of internal components and product enclosures. With the capability for fast iteration and testing, 3D printing has shortened product development cycles and allowed companies to get new products to market faster.

Apple has used 3D printing for prototyping to a very great extent in the development of new models of the iPhone. This allows the making of multiple prototypes to be tested out simultaneously and reduces the overall validation timeline while continuing to ensure that high standards of quality and performance are met.

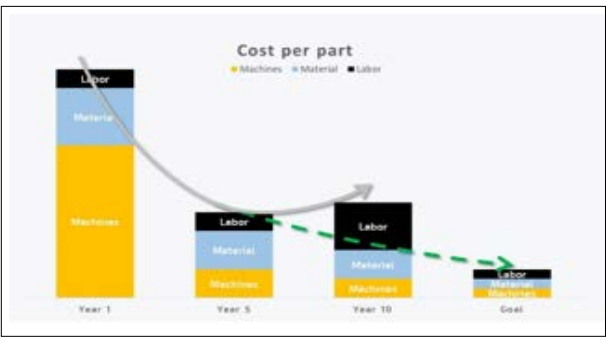

Future Trends in 3D Printing for Prototype Development

Advanced Materials

Another exciting trend in 3D printing is the development of new materials that extend prototype functionality. High performance metals, biocompatible materials, and conductive polymers are opening the creative envelope to build functional prototypes resembling the final product much more closely

Automation and AI Integration

Another emerging trend is consolidating automation and artificial intelligence into the processes constituting 3D printing. With printers operating around the clock and AI powered tools that automate optimal designs, prototyping will be faster and involve less human interaction. This in turn reduces both the cost and the time of validation.

Distributed Manufacturing

With increased utilization of 3D printing, distributed manufacturing will eventually be the manufacture of prototypes and products close to their point of use. This is a particularly relevant trend for industries applying or in need of fast turnarounds or customized products, which will include healthcare and consumer electronics [1-5].

Conclusion

With the potential for significant cost savings and reduction of validation timelines, the prospects appearing for 3D printing in prototype development are brilliant. Further developments in materials, automation, and design tools are going to make 3D printing an increasingly critical factor in accelerated product development cycles and sustained innovation across diversified industries.

From material waste shed to cost reduction of labor, 3D printing gives companies the capability to validate prototypes faster and at a lower cost than ever.

With more and more industries beginning to embrace the technology, 3D printing is well on its way toward becoming a staple tool within the prototyping process, nailing its place in the future of product development.

References

- Gibson I, Rosen DW, Stucker B (2010) Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing. Springer https://research.utwente.nl/en/publications/additive-manufacturing-technologies-rapid-prototyping-to-direct-d.

- Wohlers T (2013) Wohlers Report 2013: Additive Manufacturing and 3D Printing State of the Industry. Wohlers Associates https://wohlersassociates.com/product/wohlers-report-2013/.

- Kalpakjian S, Schmid SR (2009) Manufacturing Engineering and Technology. Pearson https://pearsonhighered.com/assets/preface/0/1/3/5/0135228603.pdf.

- Chua CK, Leong KF, Lim CS (2003) Rapid Prototyping: Principles and Applications. World Scientific Publishing.

- Pham DT, Dimov SS (2001) Rapid Manufacturing: The Technologies and Applications of Rapid Prototyping and Rapid Springer.