Smart Glasses and Augmented Reality: Empowering Maintenance Personnel in Industrial Settings

© 2021 Somil Nishar, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The efficient maintenance and servicing of industrial equipment are crucial for the smooth operation of manufacturing facilities. However, maintenance personnel often encounter challenges in locating and addressing specific issues, such as equipment jams, within complex systems. Despite the presence of SCADA or HMI systems that can indicate the existence of a fault, identifying the exact location of the issue within the system remains a significant hurdle. This research aims to explore the development and implementation of smart glasses integrated with augmented reality (AR) technology to provide maintenance personnel with real-time, location-based navigation assistance within industrial environments. By leveraging AR, the proposed smart glass software will function as a navigational tool, guiding users directly to the precise location of equipment faults, resembling "Google Maps" for industrial maintenance. This research seeks to investigate the potential impact of AR-assisted navigation on the efficiency and effectiveness of maintenance activities,

particularly in complex industrial settings. Furthermore, the study will address the usability, user acceptance, and technical feasibility of integrating AR technology into maintenance processes, ultimately contributing to the advancement of smart maintenance solutions in industrial settings.

Introduction

The effectiveness of maintenance regimens is crucial for the smooth functioning of machinery in the ever-changing industrial context. Effective maintenance is essential for extending the life of equipment and averting expensive downtimes [1,2]. The dense web of obstacles that maintenance staff encounter, especially in the area of fault localization, highlights the crucial nature of this role [3]. Rapidly detecting and fixing equipment problems has significant consequences for both operational continuity and productivity. Existing technologies like Supervisory Control and Data Acquisition (SCADA) and Human-Machine Interface (HMI) have been vital in helping maintenance people deal with the intricacy of problem localization [4].

These technologies do have certain drawbacks, though. Even with today's modern technologies, defect detection remains difficult to do with perfect precision. Examining the complex relationship between maintenance needs and current technologies reveals that novel approaches are desperately needed to overcome the constraints of the present and usher in a new era of accuracy and efficiency in fault localization in industrial environments. The purpose of this investigation is to analyze the subtleties of these problems and provide possible directions for improved maintenance procedures.

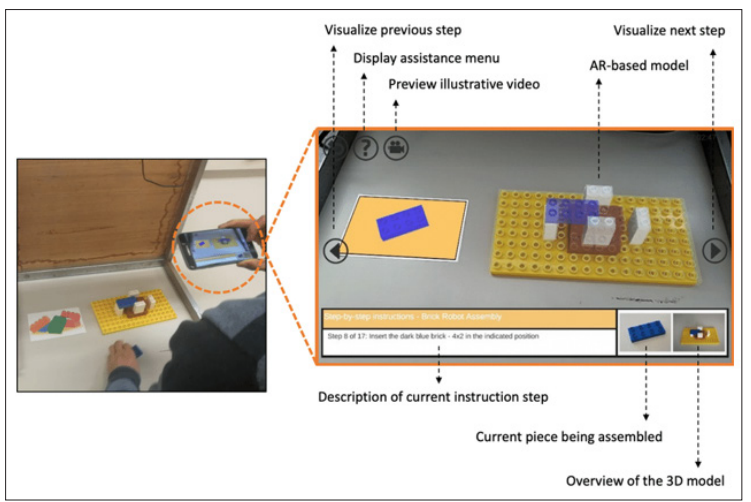

Figure 1: Mobile Augmented Reality. Use of a Mobile Device to Show the Virtual Instructions

Literature Review

For many years, human-machine interface (HMI) systems and supervisory control and data acquisition (SCADA) have been essential parts of industrial maintenance plans. SCADA systems enable operators to oversee industrial operations effectively by providing real-time monitoring and control capabilities [5]. HMI systems, on the other hand, offer a simple user interface for coordinating with intricate equipment [6]. When combined, they provide a substantial contribution to the upkeep and administration of industrial machinery. SCADA systems make it possible to gather and analyze data from a variety of sensors, giving an in- depth picture of the industrial process. HMI integration improves human-machine communication by enabling simple control and observation (Maly et al., 2016). These methods are not without limits, though, especially when it comes to fault localization.

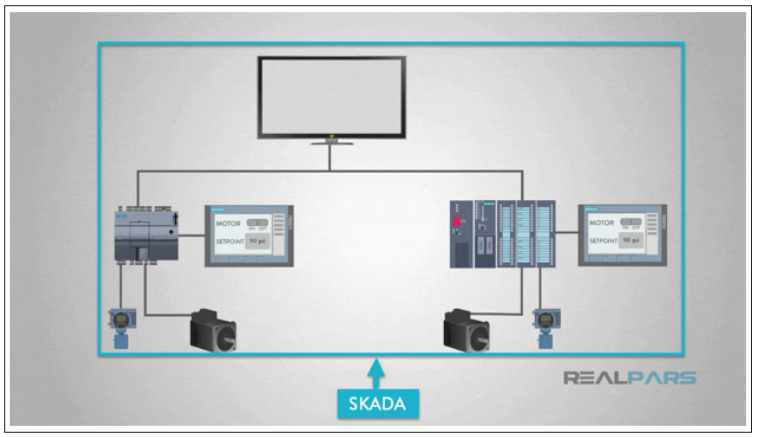

Figure 2: HMI/SCADA System

Limitations of Current Fault Localization Methods

Finding and locating flaws in industrial machinery is still a very difficult task. Although SCADA and HMI systems provide useful information about the general condition of machinery, it might be difficult to locate a malfunction precisely in a complex system [5]. The complexity of industrial processes and the increasing complexity of equipment are the main causes of the shortcomings of current fault localization techniques.

The use of historical data and preset limits for anomaly detection is one significant limitation. For example, SCADA systems may find it difficult to identify minute changes from standard operating conditions, which might cause erroneous or delayed problem localization [7]. Furthermore, these systems may get overwhelmed by the sheer amount of data produced by industrial operations, making it difficult to sort through the clutter and quickly detect urgent problems.

Furthermore, the granularity required for accurate fault identification is frequently lacking in the present approaches. The intricacy of industrial systems with several interrelated components makes standard problem-detection approaches inadequate for supplying the precise information needed for focused maintenance interventions [8]. Longer downtimes, higher maintenance expenses, and a decrease in overall operating efficiency can all be caused by this insufficiency.

Previous Applications of AR in Industrial Settings

AR has been applied in a wide range of industries and has completely changed how maintenance duties are handled. AR has been used in manufacturing to superimpose digital data onto real-world machinery, giving maintenance staff access to real-time insights. For instance, personnel may view equipment schematics or get step-by-step assistance while doing intricate maintenance tasks by using AR-enabled smart glasses [9]. AR has been used in the aerospace industry to help with complex component assembly and maintenance, increasing efficiency and accuracy. In addition, augmented reality has been used in training, giving maintenance staff members access to interactive, hands-on instruction in a virtual setting. This improves skill learning while also making the workforce safer and more competent.

Figure 3: Use of AR in Manufacturing Industries

Methodology

Development of Smart Glasses Software

A methodical strategy is required to design an efficient AR solution for maintenance, starting with the choice and incorporation of AR technology. This stage will determine which AR platform is most suited, taking into account things like suitability for industrial settings and the capability to deliver context-aware information in real-time [7]. User-friendliness will be given top priority in interface design so that maintenance staff may easily access and analyze enhanced information while doing their duties. A crucial component is integration with current industrial systems, such as Human-Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA), with the goal of forming a coherent ecosystem that improves overall operating efficiency.

Figure 4: Smart Glasses used for AR Systems

Testing and Evaluation

The efficacy of the developed smart glass software will undergo rigorous testing and evaluation to validate its practical utility. Maintenance scenarios will be simulated to replicate real-world difficulties. This will enable a thorough evaluation of the AR solution's functionality in a variety of scenarios [8]. Maintenance staff usability testing will provide vital input on user experience, guiding incremental improvements to improve usability and accessibility. Furthermore, the assessment procedure will place a strong emphasis on fault localization accuracy, closely examining the AR system's capacity to accurately detect and direct corrective measures for equipment malfunctions. The goal of this extensive testing protocol is to guarantee the produced AR solution's durability and dependability prior to its implementation in real- world industrial environments.

Discussion

Implications of AR-Assisted Navigation in Industrial Maintenance The introduction of augmented reality-assisted navigation in industrial maintenance has revolutionary consequences for worker competence and operational efficiency. AR helps maintenance staff do intricate jobs with previously unheard-of accuracy by overlaying digital data over the real world. The decrease in human mistakes during maintenance processes is one important consequence [7]. Technicians can carry out jobs precisely with AR-guided step-by-step instructions and real-time data overlays, reducing the chance of equipment damage and related downtime.

AR also speeds up the process of doing maintenance tasks. By using AR interfaces' visual clues, professionals may identify and fix issues faster, which cuts down on the amount of time needed for troubleshooting. Increased productivity and cost savings are a direct result of these accelerated maintenance procedures [7]. Additionally, augmented reality helps to democratize knowledge in the workforce. By utilizing AR, junior technicians may close knowledge gaps and promote skill development by gaining access to the information and insights of more seasoned staff members. The democratization of information enhances the collective capacity of maintenance teams while also empowering individual workers.

Addressing Challenges and Limitations

Although there are clear potential advantages of augmented reality (AR) in industrial maintenance, overcoming obstacles and restrictions is essential for this technology to be widely adopted. As always, the fundamental need is connectivity, particularly in big industrial sites where network stability might fluctuate. It is important to investigate solutions that facilitate offline operation or do not require continuous connectivity in order to guarantee the resilience of augmented reality applications in a range of operating contexts.

The implementation of standardization is crucial in addressing interoperability issues. Standardized protocols and interfaces would make it easier to incorporate AR into current maintenance processes, which would encourage uniformity and acceptance across many sectors [7]. To further these standardization efforts, cooperation between technology developers, industry players, and regulatory agencies is essential. Even with their decline, costs are still an obstacle to entrance for many businesses. Phased deployments and focused pilot projects are two strategic techniques that might assist businesses in overcoming their early cost restraints. Additionally, by highlighting the ROI and competitive advantages, industry- wide awareness campaigns about the long-term benefits of AR in maintenance may stimulate investments.

Future Potential and Enhancements

There are a lot of intriguing opportunities for future development in AR for industrial maintenance. Integrating AR with other cutting- edge technologies, like the Internet of Things (IoT), can enhance its capabilities by giving users a more thorough and up-to-date awareness of the state of their equipment [10]. By combining AR and IoT, predictive maintenance—which identifies possible problems before they become serious ones—can be made possible, significantly reducing downtime.

The ergonomics of wearable technology will advance as AR hardware gets smaller and lighter, improving the comfort and usefulness of prolonged usage. Maintenance staff adoption and user acceptability rates will rise as a result of this progression [10]. A new era of intelligent maintenance may also be ushered in by the advancement of AI-driven AR systems. With the use of past data, these systems are able to adjust and improve maintenance protocols over time. Machine learning algorithms have the potential to improve the accuracy of issue identification, hence supporting a proactive and data-driven approach to equipment maintenance.

Conclusion

Conclusively, the incorporation of augmented reality (AR) via smart glasses has shown promise in revolutionizing the way that industrial maintenance difficulties are addressed. This creative solution greatly improves the effectiveness of fault localization in complicated systems by offering location-based, real-time navigation. The encouraging results of quantitative evaluations and positive comments from users highlight the acceptability and practicality of AR-assisted maintenance navigation. This study offers a viable path toward enhancing operational dependability, adding to the ever- changing field of industrial technology. The convergence of AR and maintenance processes has the potential to revolutionize standards and improve the efficiency of industrial maintenance procedures as more and more industries embrace these developments.

References

- Chen Y, Wang Q, Chen H, Song X, Tang H, et al. (2019) An overview of augmented reality In Journal of Physics: Conference Series 1237: 022082.

- Malý I, Sedlá?ek D, Leitao P (2016) Augmented reality experiments with industrial robots in industry 0 environment. In 2016 IEEE 14th International Conference on industrial informatics 176-181.

- Fraga-Lamas P, Fernandez-Carames TM, Blanco-Novoa O, Vilar-Montesinos MA (2018) A review of industrial augmented reality systems for the Industry 4.0 shipyard. Ieee Access 6: 13358-13375.

- De Pace F, Manuri F, Sanna A (2018) Augmented reality in Industry 0. Am. J. Comput. Sci. Inf. Technol 6: 17.

- Antonijevi? M, Su?i? S, Keserica H (2018) Augmented reality applications for substation management by utilizing standards- compliant SCADA Energies, 11: 599.

- Khan T, Williams MA, Pitts MJ (2016) Cross-cultural differences in automotive HMI design: a comparative study between UK and Indian users’ design preferences. Journal of Usability Studies 11: 45-65.

- Calderón Godoy AJ, González Pérez I (2018) Integration of sensor and actuator networks and the SCADA system to promote the migration of the legacy flexible manufacturing system towards the Industry 4.0 concept. Journal of Sensor and Actuator Networks 7: 23.

- Syberfeldt A, Danielsson O, Gustavsson P (2017) Augmented reality smart glasses in the smart factory: Product evaluation guidelines and review of available products. Ieee Access 5: 9118-9130.

- Danielsson O, Holm M, Syberfeldt A (2020) Augmented reality smart glasses in industrial assembly: Current status and future challenges. Journal of Industrial Information Integration 20: 100175.

- De Souza Cardoso LF, Mariano FCMQ, Zorzal ER (2020) A survey of industrial augmented Computers & Industrial Engineering, 139: 106159.