Analysis of Tool Wear and Calculation Results of Hardness Values in St 37 Steel Turning Using Characteristics

© 2023 Junaidi, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The development of lathe chisels is currently more advanced with the creation of carbide, CBN, ceramic, and inserts tool types. However, conventional chisel types, one of which is the HSS (high speed steel) chisel, are still used. ST 37 steel is a low carbon steel type that is easy to forge and easy to machine.The level of precision and surface roughness of the resulting workpiece must be in accordance with the needs. The higher the level of surface quality of the workpiece, the higher the level of precision. The research method we use is to find data, then the data obtained is graphed.

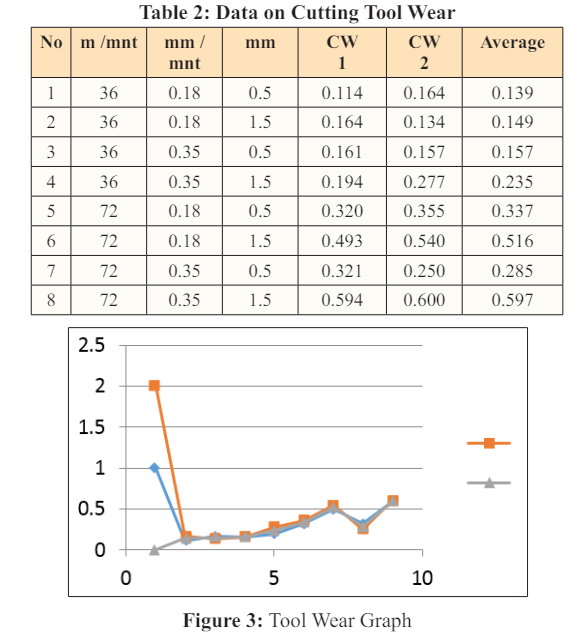

From the results of the graph it can be concluded that for the depth of cutting the greater the rotation, the greater the depth. For wear, it can be seen that the wear will be greater if the speed is increased.

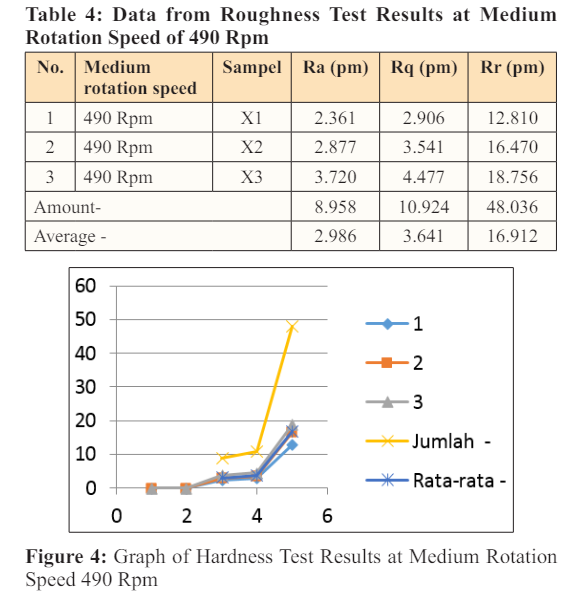

The results of the hardness test at a medium rotational speed of 490 Rpm, the greater the number of examples, the greater the results of the hardness test experienced on the test material.

Introduction

The need for the Manufacturing Industry to work with machines has become a necessity in producing products in the form of goods or services [1]. Machines already have a major role in helping humans in the production process, because by using machines, human work becomes easier and better in terms of speed and the results are certainly in accordance with the desired [2]. The work in question is in the form of turning, milling, drilling, scraping and other machining processes [3]. The machining process that is usually used in the production process requires high accuracy to get good results [4]. Accuracy, precision and surface quality are the main priorities that become a reference in the workmanship in the machining process [5]. The expected workpiece surface results from each work. The level of precision and surface roughness of the resulting workpiece must be in accordance with the needs. The higher the level of surface quality of the workpiece, the higher the level of precision [6].

The turning process using a lathe will cause an interaction between the chisel and the workpiece, resulting in the desired size [7]. Considering the importance of surface quality after turning, it must be possible to make a product with a level of roughness that complies with the criteria including cutting speed and cutting tool position [8]. The development of lathe chisels is currently more advanced with the creation of carbide, CBN, ceramic, ceramic lathe, and inserts tool [8]. Nevertheless, conventional chisel types, one of which is the HSS (high speed steel) chisel, are still used. ST 37 steel is a type of low carbon steel which is easy to forge and easy to machine [9]. The HSS lathe is widely used for machining ST 37 steel in the manufacture of gears, shafts and bolts. The lathe process is a machining process to produce cylindrical machine parts which are done using a lathe [10]. In this process, it is a cutting machine process with the main motion rotating, the workpiece is gripped and rotates on its axis, while the cutting tool moves [11]. As long as the workpiece is the result, there is a cut. The slicing process takes place, there is an interaction between the chisel and the workpiece where the workpiece is cut while the chisel experiences friction [12]. As a result of this friction, the tool wears out. In the lathe process, measuring tool wear is necessary, because in the machining process the production price is much influenced by the use of the chisel [13]. The shorter the tool life, the faster the tool must be replaced. Therefore we are required to continue to improve the efficiency and effectiveness of the machining process itself [14]. How to find out the analysis of the rotational speed on the ST 37 steel turning with the cutting force of the cutting speed using an HSS chisel on the hardness value and the heat surface of the steel by using the known characteristics of the data [11]. To determine the characteristics of the rotational speed analysis on steel turning ST 37 with a cutting force of cutting speed using an HSS chisel to the hardness value and surface heat of the steel [15]. In order for the research research of this article to be more focused and clear, the field of discussion will be limited to the following points:- The object of the cutting force on a conventional machining lathe GEDEE WEILER LZ 330 G against a ST 37 carbon steel surface

The benefits of this research are as a reference for further research on the problem of analyzing the rotational speed on turning ST 37 steel with cutting force from cutting speed using an HSS chisel on the hardness value and surface heat of the steel [14].

Theory Basis

The rapid development of industry at this time, especially the machinery industry, has spurred the development of technology for the manufacture of basic materials such as steel [7,16]. Considering these conditions, adequate mechanical properties are needed, so that the service life can be increased [17]. To overcome this, usually machining components are heat treated [18]. St 37 steel, which is equivalent to AISI 1045 with a chemical composition of 0.5% C, 0.8% Mn, and 0.3% Si, is one of the steels produced for the manufacture of various machining components. [19]. To improve the mechanical properties of St 37 steel, a heat treatment process is applied, by means of surface hardening (Carburizing)[20] . One of the surface hardening processes is solid carburizing, which aims to increase the carbon content (C) in the surface layer of steel so that the surface hardness is greater than the inside [17,21]. The solid carburizing process can result in improved mechanical properties of machining components, including: 1. Increased surface hardness [22]. 2. Increased wear resistance of the contact surface. Alloy steel is steel that is formed according to the desired purpose to improve the mechanical properties or basic properties of the steel which is adjusted to the basic elements in the steel [23]. In this alloy steel is divided into 2 types, namely: Low alloy steel (special alloy elements < 8.0 %), High alloy steel (special alloying elements > 8.0 %) [24]. Characteristics of St 37 Steel (AISI 1045) St 37 steel is medium carbon steel equivalent to AISI 1045, with a chemical composition of Carbon: 0.5%, Manganese: 0.8%, Silicon: 0.3% plus other elements [8]. With a hardness of 170 HB and a tensile strength of 650 -800 N/mm2. In general, St 37 steel can be used directly without undergoing heat treatment, unless special applications are needed [25].

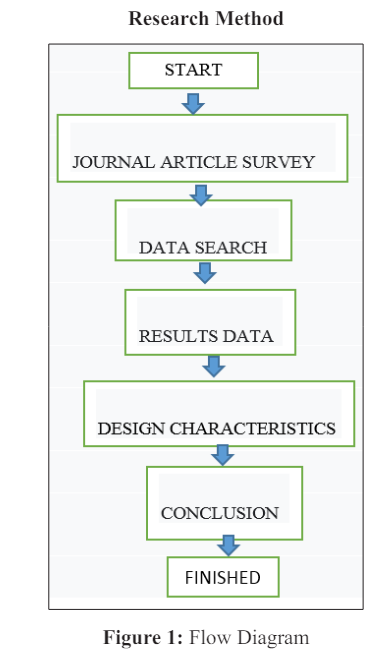

Figure 1 is a flowchart showing the process of making articles. The first step is to start taking the data that I have been looking for, the results of research in the laboratory with steel ST.37 has displayed its citation in the bibliography. Furthermore, the data is designed in making characteristics and the results can be analyzed and conclusions drawn from the analysis.

Conclusion

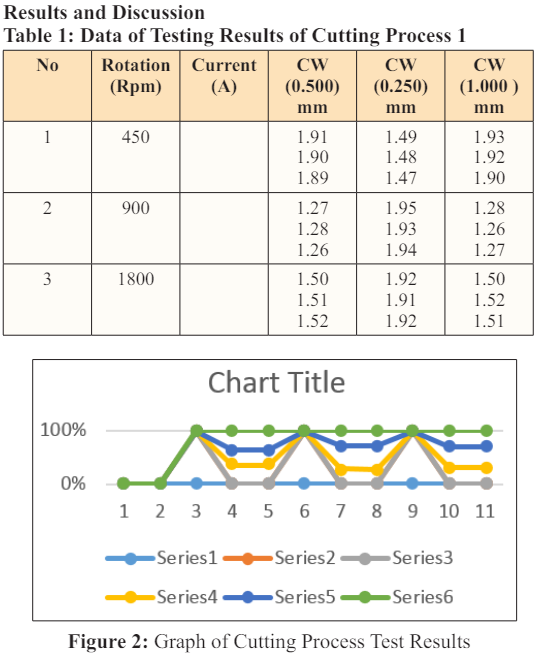

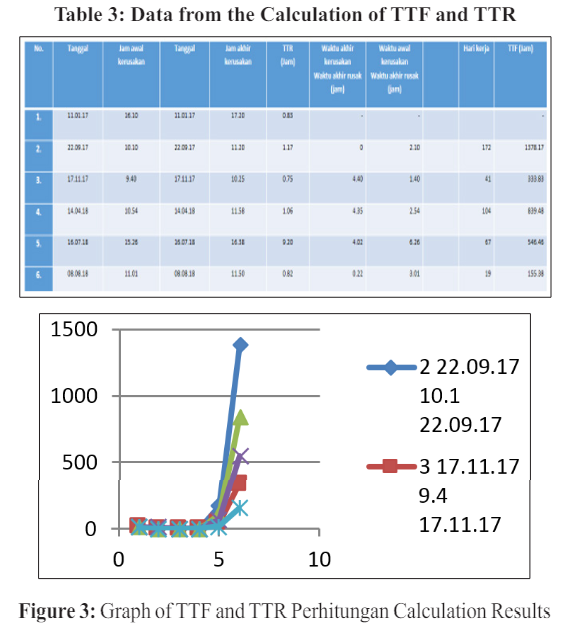

From the 450 rpm rotation with a cutting depth of 0.25 mm, three tests got a smaller depth, while the 900 rpm rotation with a cutting depth of 0.25 mm, three times the test got a smaller depth, while with 1800 Rpm rotation, the results got more depth large. With a cutting depth of 0.50 mm with a rotation of 450 rpm the depth is getting smaller. While at 1000 rpm the depth results change. In Figure 2 the Wear Graph shows that the wear will be greater if the speed increases. From Figure 3, it can be seen that the greater day, the greater the TTF. From the graph of Figure no. 4. the results of the hardness test at a medium rotation speed of 490 Rp. mg, the greater the number of examples, the greater the results of the hardness test experienced on the test material.

References

1. J Junaidi, S Hestukoro, A Yanie, J Jumadi, E Eddy (2017) Implementation Analysis of Cutting Tool Carbide with Cast Iron Material S45 C on Universal Lathe in Journal of Physics: Conference Series 930: 012044.

2. J Junaidi, S Hestukoro, I Roza, D Morfi Nst, Weriono (2018) Process Analysis of High Speed Steel Cutting Calculation (HSS) with S45 C Material on Universal Machine Tool. Int.

J. Innov. Sci. Res. Technol 3: 447-456.

3. J Junaidi (2020) Working process of TU 3a CNC frais machine using software system. Int. J. Eng. Technol 9: 658.

4. J Junaidi (2022) Effect of Heat Treatment on Aluminum 5083 on Impact Test. in sem 23-29.

5. Junaidi, Weriono, I Roza (2018) Irrigation Water Debit Analysis that will be used on Micro Power Plant in SEI. Rampah Sub-District of Serdang Bedagai Regency. Int. J. Innov. Sci. Res. Technol 3: 311-317.

6. Ratlalan RM (2019) Variasi Kecepatan Putaran Dan Kedalaman Gaya Potong Mesin Bubut Gedee Weiler LZ 330 G Terhadap Permukaan Baja Karbon ST 37. J. Rekayasa Mesin 14: 113-120.

7. I Gusandi Panjaitan, Junaidi, FA Kurniawan (2022) Analisis Pemeliharaan Cgr (Compact Gas Ramp) Menggunakan Metode Reliability Centered Maintenance (Rcm) Di Pltmg Balai Pungut-Duri Online 17: 257-261.

8. B Anwar, Yofianus Limbong Kelen, A Muhammad Idkhan (2020) Pengaruh Kecepatan Putar Terhadap Nilai Kekasaran Hasil Pembubutan Baja St 37. J. Rekayasa Mesin 1-14.

9. Junaidi, T Siagian, Irfansyah Siregar, H Lubis (2018) Characteristics of St.37 Steel Materials with Temperature and Time on Heat Treatment Test using Furnace. Int. J. Innov. Sci. Res. Technol 3: 49-53.

10. Junaidi, A Abdirullah, Bhagaskara Teguh Samudra (2019) Characteristic Analysis of Knaf Fiber with Impact Loading for Design with Specifications Size 80 / 20.70 / 30.60 / 40.50

/ 50.40 / 60. Tek. Mesin Unhar 1: 1-7.

11. Agus Syahabuddin (2019) Analisis Perawatan Mesin Bubut CY-L1640G Dengan Metode Reliability Centered Maintenance (RCM) DI PT. Polymindo Permata. J. Rekayasa Mesin 2: 2620-5793.

12. Junaidi, Soni Hestukoro, Ahmad Yanie, Irfansyah Siregar, Eddy Eddy (2018) Analysis Effects of Exposure time on Long Steel Stainless Steel Material Proper which Experience Stress Corrosion Cracking. in AISTSSE https://eudl.eu/doi/10.4108/ eai.18-10-2018.2287411.

13. DS Agus Suprihanto, Dwi Basuki Wibowo (2010) Pengujian Lelah Siklus Rendah Besi Cor Kelabu. Rotasi 12: 1-4.

14. Fahim Barok Al Azib (2017) Pengaruh Variasi Kecepatan Potong, Gerak Makan, Dan Kedalaman Potong Pada Mesin Bubut Terhadap Tingkat Keausan Pahat Hss. J. Rekayasa Mesin 1-10.

15. M S E Bougoffa, M N Bachir bey, C Benouali, T Sayah, M Fellah, et al. (2021) Dry Sliding Friction and Wear Behavior of CuZn39Pb2 and AA7075 Under Industrial and Laboratory Conditions. J. Bio- Tribo-Corrosion 7: 38.

16. Junaidi (2019) Analisa Perhitungan Gaya Potong Pada Proses Pembubutan Terhadap Material Dengan Pahat Carbide Menggunakan Karakteristik. In Semnastek Uisu 2019: 226- 232.

17. A I Junaidi, Fadly Kurniawan Nasution, Din Aswan Ritonga (2021) Analisis Karakteristik Pelek Mobil Avanza G Toyota Akibat Terjadinya Tubrukan Dengan bus Tangki Menggunakan Metode Uji Perlakuan Panas dan Impak. in Seminar Nasional Teknologi Edukasi dan Humaniora 2021, ke-1 1022-1038.

18. Junaidi (2021) Karakteristik Instalasi Equipment Deodorizer Di Proyek Cpo Plant. in Semnastek UISU 146-150.

19. MBP Junaidi, Anggri Abdirullah (2020) Implementasi Analisis Karakteristik Komposit Serat Knaf Menggunakan Metode Uji Impak Untuk Beberapa Jenis Rincian Ukuran Kecil. JMEMME 4: 94-101.

20. Junaidi (2020) Menganalisis Cetakan Pasir Pada Proses Pengecoranaluminium Daur Ulang Terhadap Struktur Mikro Dan Kekerasancoran Pulli Menggunakan Karakteristik. in Semnastek UISU 169-173.

21. Junaidi (2019) Analisa Karakteristik Over Size Terhadap Pengaruh Hasil Pengukuran Keausan ,Keovalan Dan Ketirusan Pada Blok Selinde. Piston 4: 40-43.

22. A Waskito, S Lubis, W Swadana, M M Hariadi, Junaidi (2020) Analisa Karakteristik Sudut Chamber dan Gaya Tekan Akhir Terhadap Kekuatan Tarik dan Porositas Sambungan Las Gesek Pada Paduan Al-Mg-Si. Tek. Mesin Unhar 1: 1-7.

23. A Yani, Junaidi, M Irwanto, A H Haziah (2019) Optimum reactive power to improve power factor in industry using genetic algortihm. Indones. J. Electr. Eng. Comput. Sci 14: 751-757.

24. T Riyadi (2011) Cara Kerja Dan Troubleshooting Sistem Bahan Bakar Isuzu Panther 4JA1-L. in Tugas Akhir, Semarang: Universitas Negeri Malang 1-70.

25. Junaidi (2018) Karakteristik Material Baja St.37 dengan Temperatur dan Waktu Pada Uji Heat Treatment menggunakan Furnace. J. Uhamzah 8: 43-49.