Analysis of the Influence of Fractured Reservoir Heterogeneity and Injection Rate on Oil Displacement Effect

© 2021 Zhang Yun, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Based on the characteristics of actual fractured heterogeneous reservoirs, similarity criteria are designed. This paper carried out physical experiments considering the fracture density and matrix permeability. The heterogeneity of fractured reservoirs and the displacement effect under different injection rates of displacement fluids are studied. The results show that under the same injection rate, the degree of recovery decreases with the increase of permeability. The average reduction range of different displacement fluids is 6-20%. The degree of recovery increases as the injection rate increases. But the increase will be reduced, and different injection media will be different. This research provides a reliable basis and guiding significance for the rational combination of development layers and the determination of a reasonable injection rate.

Introduction

Fractured reservoirs generally develop fractures, and their heterogeneity is strong [1]. In the early stage of development, the heterogeneity has a great influence on the development effect, especially after the implementation of water injection development, the heterogeneity of the reservoir itself is aggravated, resulting in serious water channeling and low recovery [1,2]. In order to improve the recovery rate of heterogeneous reservoirs, tertiary oil recovery technology has been developed in China. However, due to most of the high cost and other reasons, it is difficult to promote and apply on a large scale [3]. The dual role of oil, and the advantages of wide gas source, low cost, clean and environmental protection, safety and reliability, and wide application range have attracted wide attention at home and abroad in recent years [3-5]. Studies have shown that the heterogeneity and injection rate of fractured reservoirs are important factors affecting the technology, but there are few studies on this factor at present, so combined with the actual reservoir temperature and pressure system (68.9°C, 19.6 MPa) and the effective permeability of the reservoir (75.6-3879.4×10-3μm2) [6-11]. The heterogeneity and injection rate of fractured reservoirs were studied through laboratory experiments using a double-tube model. On the basis of water flooding, nitrogen/nitrogen foam technology was used. To further improve the impact of crude oil flooding effect, it has important guiding significance and basis for the implementation of nitrogen/nitrogen foam in heterogeneous reservoirs to improve oil recovery.

Similarity Criterion Design for Physical Experiment of Fractured Reservoir

In the process of the three-phase flow of oil, water, and gas in the fracture medium, the physical variables and their meanings that may be involved are shown in the following table 1 [12,13]. The design of the physical model should satisfy geometric similarity, motion similarity, and dynamic similarity. Similarity design should be carried out on the characteristic parameters of fractured reservoirs, and the sequence of well opening, production time and fluid production in the experimental process should be similar to actual production. For geometric similarity, fractures in fractured reservoirs are the main flow channels, and similar designs should be carried out around the fractures.

Table 1: The physical quantities and their dimensions involved in fluid flow physics experiments

|

Classification |

Number |

Physical Quantity |

Symbol |

Dimension |

|

Classification Number Physical |

1 |

quality |

M |

[M] |

|

2 |

time |

T |

[T] |

|

|

3 |

length |

L |

[L] |

|

|

Quantity Symbol Dimension |

4 |

Water phase viscosity |

Μw |

[ML-1T-1] |

|

5 |

Oil phase viscosity |

Μo |

[ML-1T-1] |

|

|

6 |

Vapor viscosity |

μg |

[ML-1T-1] |

|

|

7 |

Water phase density |

ρw |

[ML-3] |

|

|

8 |

Oil phase density |

ρo |

[ML-3] |

|

|

9 |

Gas phase density |

ρg |

[ML-3] |

|

|

10 |

Water velocity |

vw |

[LT-1] |

|

|

11 |

Oil phase flow rate |

vo |

[LT-1] |

|

|

12 |

Gas flow rate |

vg |

[LT-1] |

|

|

13 |

Water mass flow |

Qw |

[MT-1] |

|

|

14 |

Oil phase mass flow |

Qo |

[MT-1] |

|

|

15 |

Gas mass flow |

Qg |

[MT-1] |

|

|

16 |

Pressure, capillary pressure |

P, Pc |

[ML-1T-2] |

|

|

17 |

Acceleration of gravity |

g |

[LT-2] |

|

|

|

18 |

Permeability |

K |

[L2] |

|

19 |

crack density |

nf |

[L-1] |

|

|

20 |

Absolute roughness of crack |

e |

[L] |

|

|

21 |

Crack spacing |

B |

[L] |

|

|

22 |

Crack opening |

b |

[L] |

|

|

23 |

Well diameter |

rw |

[L] |

|

|

24 |

Interfacial tension |

σ |

[MT-2] |

|

|

25 |

Statistical wetting angle |

θ |

1 |

|

|

26 |

Fluid compressibility |

CL |

1 |

|

|

27 |

Rock compressibility |

Cr |

1 |

|

|

28 |

Oil phase flow coefficient |

Kro |

1 |

|

|

29 |

Water phase flow coefficient |

Krw |

1 |

|

|

30 |

Gas flow coefficient |

Krg |

1 |

|

|

31 |

Oil saturation |

So |

1 |

|

|

32 |

Water saturation |

Sw |

1 |

|

|

33 |

Gas saturation |

Sg |

1 |

|

|

34 |

Coordination number |

ξ |

1 |

|

|

35 |

Filling degree |

η |

1 |

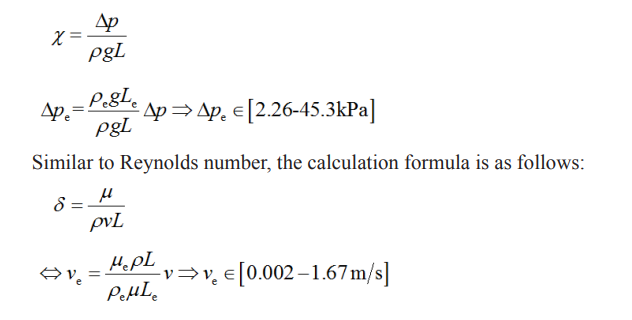

In the dynamic similarity, due to the development of large fractures, the fluid flow velocity is high, and the fluid flow is similar to the pressured pipe flow. Therefore, the model similarity design should satisfy the Reynolds number equal. In addition, the ratio of pressure to gravity affects the oil-water distribution in the displacement process to a certain extent, and the cubic law under multiple fractures mainly describes the fluid flow characteristics in the fractures, but from the perspective of similar theoretical design, the same In physical simulation, it is difficult to realize multiple similarity criteria at the same time, and can only focus on partial simulation. Therefore, the Reynolds similarity criterion should be satisfied, and the model and experimental parameters should be adjusted to make the physical simulation as close as possible to satisfy the pressure to gravity ratio and the cubic law under multiple fractures; other important parameters such as the coordination number (connected by the reservoir) The number of fractures) is used as a reservoir characteristic parameter for similar design. Based on analysis and integration, similar criteria that can reflect the main characteristics of reservoir development are determined, as shown in Table 2.

Table 2: The physical quantities and their dimensions involved in the oil-water-gas three-phase flow in the fracture medium

|

category |

Number |

Similarity Criteria |

Physical meaning |

|

Movement and power are similar |

1 |

ΔP / (ρgL) |

Ratio of injection pressure to gravity |

|

2 |

μ / (ρvL) |

Similar to the Reynolds number, the ratio of inertial resistance to viscous resistance |

|

|

3 |

Q / (ρvL2) |

The relationship between injection volume and flow |

|

|

4 |

(vμL) / (nfb3ΔP) |

The law of cube under multiple cracks |

|

|

Similar geometric |

5 |

ξ |

Coordination number |

|

6 |

η |

Filling degree |

|

|

feature parameters |

7 |

rw/L |

Ratio of wellbore radius to reservoir thickness |

The fracture density, coordination number, and filling degree are as close to the actual reservoir as possible, and the main requirements are: the ratio of pressure to gravity, the similar Reynolds number, and the characteristics of fracture distribution.

The two physical quantities mainly used in the experiment are:

The ratio of pressure to gravity is similar, and the calculation formula is as follows:

Physical Experiment of Heterogeneous Fracture Model

Experiment of Oil Displacement Effect

The density of crude oil in the test area is 0.91 g/cm3, the viscosity of crude oil under reservoir conditions is 7.98 mPa.s; CaCl simulated formation water, with a salinity of 30288 mg/L; anionic compound foaming agent DQ-XA03.

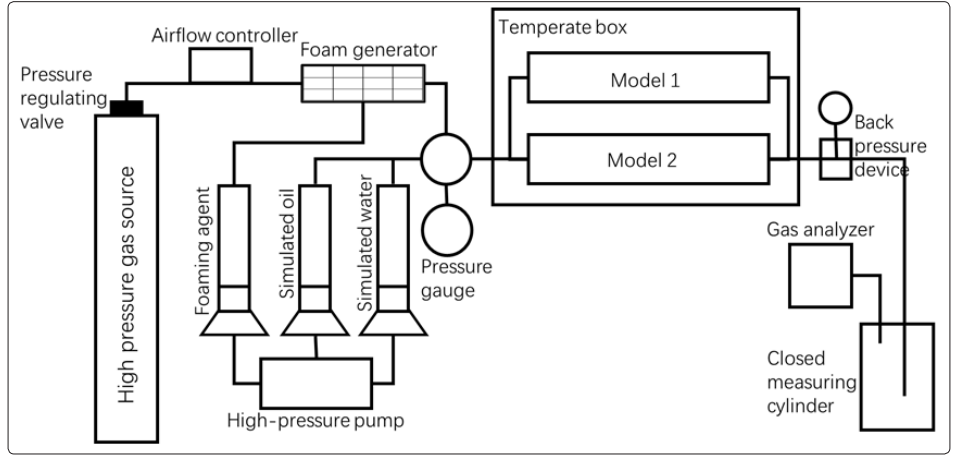

The experimental flow chart (Figure 1) mainly includes a nitrogen injection system, a displacement system, and a measurement and detection system. The injection system is mainly composed of a nitrogen high-pressure tank, a high-pressure pump, an intermediate container, a flow meter, and a pressure reducing valve; the displacement system is mainly composed of a thermostat and a high- temperature and high-pressure crack-etched sand-filled pipe (middle crack, surrounding sand); The measurement and detection system is mainly composed of a back pressure valve, a detector, and a closed measuring cylinder. Model 1 contains 2 cracks, and model 2 contains 6 cracks.

Figure 1: Experimental flow chart

Experimental Principle and Steps

Fill the models with different fracture densities according to the experimental requirements; use the dual-tube model to simulate the heterogeneity of the reservoir (different fracture densities, different model permeability), in the optimal nitrogen foam (formation water foaming agent solution concentration is 0.5wt %, the gas-liquid ratio is 1:1), to study the influence of reservoir heterogeneity and injection rate on the displacement effect of nitrogen/nitrogen foam [14-17].

First, establish the irreducible water saturation field for different fracture density models (sand fill and fracture density are different to achieve different permeability models); secondly, connect the models according to the experimental requirements; finally, perform corresponding displacement experiments under the reservoir temperature and pressure system ( Water flooding → nitrogen foam flooding → nitrogen flooding → subsequent water flooding) until no oil is produced at the outlet end, record the relevant parameters and analyze them.

Analysis of Reservoir Heterogeneity Oil Displacement Effect

The Influence of Reservoir Heterogeneity on Displacement Effect

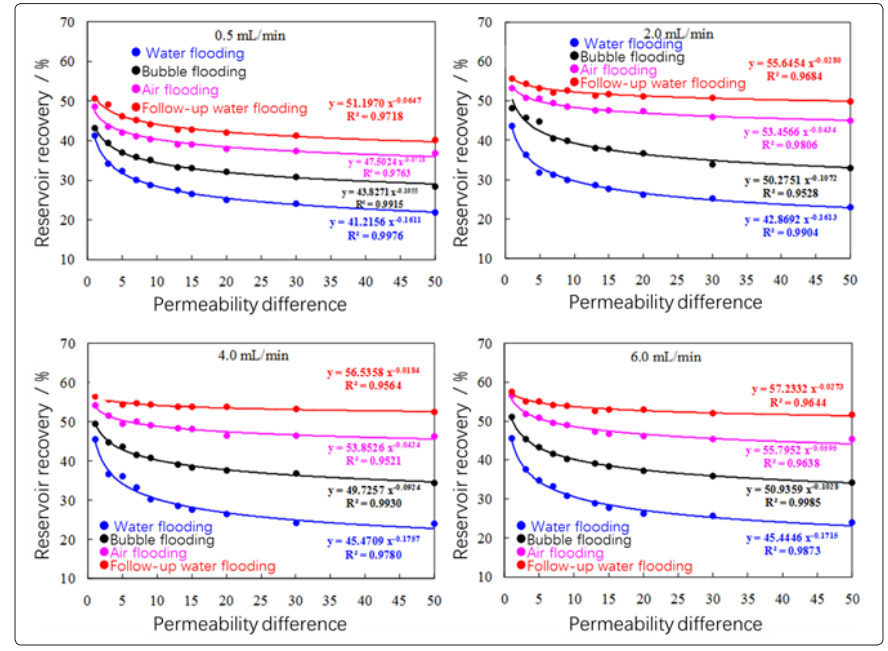

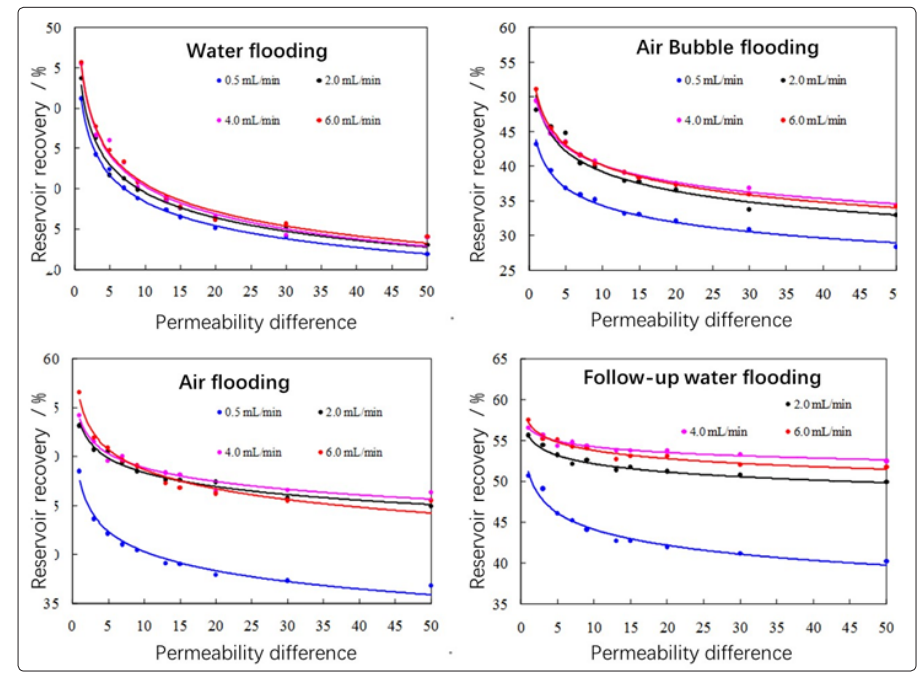

Figure 2: The relationship curve between the permeability difference and the degree of recovery under different injection rates

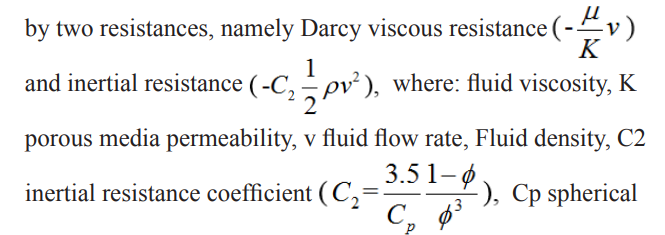

Studies have shown that reservoir heterogeneity is one of the important factors affecting the effect of nitrogen/nitrogen foam displacement. Figure 2 shows the relationship between different permeability levels and recovery levels at an injection rate of 0.5- 6mL/min. It can be seen from the experimental results that at the same injection rate, when the permeability difference increases (1→50), the recovery degree of water flooding, nitrogen foaming, nitrogen flooding and subsequent water flooding all decrease, but each range is different, namely 0.5 When mL/min is reduced by 19.28%, 14.80%, 11.70%, and 10.50% respectively; when 2.0mL/min is reduced by 20.68%, 15.15%, 8.25%, and 5.70%;when 4.0mL/min Decrease by 21.60%, 15.10%, 7.85%, and 4.10% respectively; at 6.0mL/min, decrease by 21.66%, 16.82%, 11.10% and 5.81% respectively; under the same injection rate, the recovery degree varies with As the permeability difference increases, it decreases. The reason for the analysis is that: when the displacement fluid flows in porous media, it is mainly affected

particle diameter or non-spherical equivalent diameter [8].Under the same injection rate of the same displacement fluid, the resistance in different permeable layers is also different, that is, the resistance factor in the high-permeability layer is smaller, and the relative amount of displacement fluid passing through is relatively large, resulting in a relatively large amount of ineffective displacement fluid. Eventually lead to lower crude oil recovery. Nitrogen foam system has the performance of “plugging water but not oil” and “blocking high but not low”, that is, improving the heterogeneity of the reservoir, changing the flow direction of subsequent displacement fluid, increasing the amount of displacement fluid entering the low-permeability layer, and reducing The amount of ineffective displacement fluid increases the oil displacement efficiency; in addition, the nitrogen in the nitrogen foam system can also react with crude oil at low temperature to further improve the oil recovery. Subsequent water flooding can still improve oil recovery, mainly because the heterogeneity of the reservoir has been improved to a certain extent. Through the experimental results, combined with the actual production process of the oilfield, it is possible to combine the development layers according to the reasonable permeability difference, increase the oil displacement efficiency, and achieve the purpose of improving the oil recovery.

Influence of Injection Rate on Displacement Effect

Another important factor that affects the nitrogen/nitrogen foam displacement effect is the injection rate. Figure 3 shows the recovery degree curve at the injection rate of 0.5-6mL/min under different displacement fluids. It can be seen from the experiment that the injection rate is within a certain range (0.5-6.0mL/min), under the same permeability level difference, the recovery degree increases with the increase of the injection rate, but the increase will be reduced; where the injection rate When the rate is 2.0mL/ min, the degree of recovery increases the most, with 2.5% for water flooding, 7.90% for nitrogen foam flooding, 9.50% for nitrogen flooding, and 8.78% for subsequent water flooding. The analysis shows that when the displacement fluid flows in the porous medium, the Darcy viscous resistance and the inertial resistance both increase with the increase of the fluid velocity, that is, the scouring ability of the displacement fluid increases with the increase of the injection rate, so it can Carrying out more crude oil leads to an increase in the degree of recovery; however, when the injection rate of the displacement fluid increases, the time for the displacement fluid to rush along the large channel is shortened, resulting in a decrease in the degree of recovery. On the whole, the final recovery factor still increases with the increase of the injection rate of the displacement fluid. Combining the actual production process of the oil field, the optimal injection rate of the reservoir is determined, and the crude oil recovery rate is accelerated to achieve the best economic benefits.

Figure 3: The relationship between injection rate and recovery degree under different displacement fluids

Conclusion

- The heterogeneity of fractured reservoirs has a significant effect on nitrogen/nitrogen foam displacement. At the same injection rate, the degree of recovery decreases with the increase of the permeability difference (1→50), and the degree of recovery of water flooding, nitrogen foam, nitrogen flooding and subsequent water flooding all decrease, respectively, with an average decrease of 8 and 17.1 , 9.7, 6.5 percentage points.

- The injection rate is within a certain range (0.5-6.0mL/min), and under the same permeability level difference, the recovery degree will increase with the increase of the injection rate, but the increase will be reduced; the injection rate is 0 The degree of recovery increased the most at mL/min, with water flooding by 2.5%, nitrogen foam flooding by 7.9%, nitrogen flooding by 9.5%, and subsequent water flooding by 8.7%.

- The ultimate recovery factor is related to factors such as reservoir heterogeneity and displacement fluid injection The development strata can be optimized and a reasonable injection rate can be determined according to the experimental results to achieve the best economic benefits.

References

- An Guirong, Qu Yaguang, Sha Yanhong, et (2013) Analysis of the influence degree of reservoir plane heterogeneity on waterflooding development effect [J]. Drilling & Production Technology 36: 45-47.

- Zhang Wei, Fan Guangmei (2013) The impact of reservoir heterogeneity on oilfield development: Taking M area of Ansai Oilfield as an example [J]. China Petroleum and Chemical Standards and Quality 15: 185-186.

- Pu Haiyang, He Zhong (1996) The influence of the heterogeneity of the longitudinal permeability of the oil layer on the recovery effect of steam flooding [J]. Petroleum Exploration and Development 23: 50-53.

- Wang Jiexiang, Li Na, Sun Hongguo, et (2008) Experimental study on nitrogen foam flooding of heterogeneous reservoirs for enhanced oil recovery [J]. Petroleum Drilling Technology 36: 4-6.

- Wang Jiexiang, Zhang Qi, Li Aishan, et al. (2003) Laboratory experiment study of nitrogen injection flooding [J]. Journal of China University of Petroleum (Edition of Natural Science) 27: 73-75.

- Alvarez J M, Rivas H J, Rossen W R (1999) Unified Model for Steady-State Foam Behavior at High and Low Foam Qualities [C]. Spe56825 4: 3-6.

- Wu Zhongzheng, Li Huabin, Guo Chengfei, et (2015) The effect of permeability difference on nitrogen foam flooding effect [J]. Oilfield Chemistry 32: 83-87.

- Bi Yiquan, Liu Liqin (2000) Study on the heterogeneity and sensitivity of Zheng408 glutenite reservoir in Wangzhuang Oilfield [J]. Petroleum Exploration and Development 27: 42-44.

- Masoud Hadipoor, Hadi Taghavi, Hamed Taghavi (2020) Experimental investigation of CO2 injection performance in heterogeneous reservoirs: Parametric analysis [J]. Petroleum Science and Technology 38.

- Guo Xiao, Du Zhimin (2004) The influence of heterogeneity on the productivity of horizontal wells [J]. Petroleum Exploration and Development 31: 91-93.

- Energy-Oil and Gas Research; Reports from Chinese Academy of Sciences Describe Recent Advances in Oil and Gas Research (Characteristics and the Formation Mechanism of the Heterogeneous Microfractures In the Tight Oil Reservoir of Ordos Basin, China) [J]. Energy & Ecology 2020.

- Deng Yinger, Liu Ciqun (1999) The influence of injection rate on the development of low-permeability oilfields [J]. Journal of Southwest Petroleum University (Natural Science Edition) 21: 21-24.

- Li Zhenpeng (2009) Research on single-phase fluid flow characteristics in porous media channels of pebble bed [D]. Harbin Engineering University.

- Tang Junwei, Jia Ailin, He Dongbo, Wang Weihong, Fan Lihong, Bai Quanming, Liu Discussion on development technology of Sulige gas field with low permeability and strong heterogeneity [J]. Petroleum Exploration and Development, 2006, 33(1): 107-110.

- Abhinav Kumar, Vikas Mahto, Sharma VP (2020) Reinforced preformed particle gel: Synthesis, characterization and performance evaluation for water shut-off jobs in heterogeneous reservoir [J]. Journal of Petroleum Science and Engineering 193.

- Li Qiuyan, Yue Xiang’an, Zhang Lijuan, Husein Maen (2020) Production performance by polymer conformance control in ultra-low permeability heterogeneous sandstone reservoirs produced under their natural energy [J]. Journal of Petroleum Science and Engineering 193.

- Nanotechnology-Nanoparticles (2020) Reports from Imam Hossein University Highlight Recent Findings in Nanoparticles (Flooding numerical simulation of heterogeneous oil reservoir using different nanoscale colloidal solutions) [J]. Technology News Focus.