Author(s): Alan Ok*, Ken Jung, Himanshu Ramesh Lamba and Juan Carlos Verardo

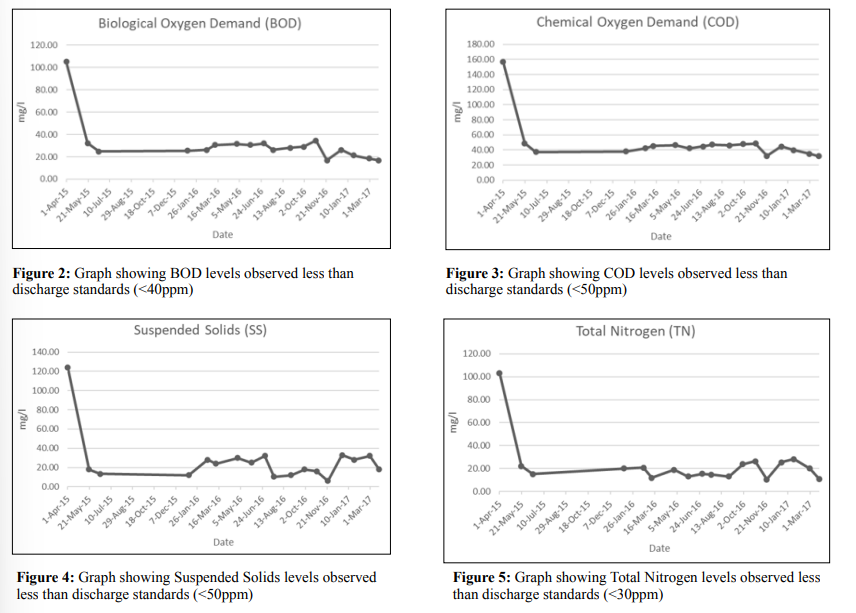

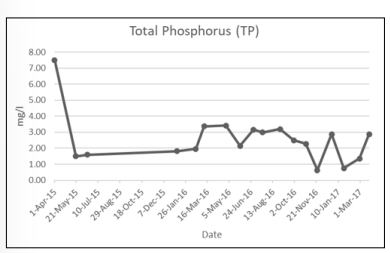

Bioaugmentation Technology was implemented in a South Korean slaughterhouse in order to meet stricter effluent standards. In the two years since introducing Bioaugmentation into the effluent treatment process, BOD, COD, SS, TN, and TP levels were maintained below required standards. The slaughterhouse has been able to reduce dosing costs associated with Bioaugmentation while sustaining improved effluent quality. With the help of Bioaugmentation, overall plant stability was improved, and previously proposed plant expansion proved to be unnecessary, resulting in significant capital avoidance.

One of the main concerns that arise from the pig industry is the pollution of air and water. The water pollution is caused by not implementing proper disposal or treatment methods of pig manure. Pig manure waste which is highly concentrated with nitrogen and phosphorus nutrients causes significant pollution. This waste when discharged untreated is also a cause of eutrophication of lakes [1]. Typical wastewater analysis for the industrial pig slaughterhouse wastewater includes chemical oxygen demand (COD), biological oxygen demand (BOD), total nitrogen (TN), total phosphorus (TP) and total suspended solids (TSS). To avoid any negative effects on aquatic life, it is important that the wastewater from the slaughterhouse should be treated before it is released into natural water bodies [2].

Addressing the treatment of industrial wastewater for reuse presents decision-makers with challenges, marked by various hurdles. Inefficient treatment options, high-cost implications, inadequate infrastructure, limited financial support, and a lack of technical know-how contribute to the complexity of this task. The existing conventional methods not only fail to deliver economic advantages to industries but also come with certain disadvantages.

The severity of the challenge is heightened by the uncontrolled release of untreated industrial wastewater into open drains, lakes, and rivers. This not only leads to environmental pollution but also poses significant health risks to the surrounding areas. The need for innovative and sustainable solutions is evident to overcome these complex issues and ensure the responsible management of industrial wastewater [3].

Wastewater treatment is achieved through a sequential integration of diverse physical unit operations, as well as chemical and biological unit processes. The efficiency of a treatment plant is dependent not only on its appropriate design and construction but also on effective operational management and maintenance practices [4]. Biological treatment plays a vital and essential role in the operations of every wastewater treatment facility [5]. Poor performance in biological treatment could be attributed to a deficiency in the abundance of a particular microorganism. In some instances, despite the presence of strains capable of carrying out similar functions and the common occurrence of metabolic versatility in environmental bioprocesses, it is more likely that the degradation of a specific target contaminant can only be achieved by a very precise mixture of microorganisms [6]. Bioaugmentation refers to augmenting beneficial microorganisms in a polluted environment that has the ability to breakdown complex organic compounds. Bioaugmentation offers an affordable solution for wastewater treatment, is easy to implement, and demands no complex hardware installations [7].

The slaughterhouse in South Korea examined in this study processes approximately 1,600 pigs on a daily basis. In order to comply with the wastewater discharge standards at this production site, a Bioaugmentation program was implemented. The primary objective of this study was to examine how bioaugmentation influences various parameters in wastewater, aiming to avoid the need for additional expenses related to plant expansion and validate if Bioaugmentation can sustain the long-term performance of the plant. This study focuses on key effluent measurements throughout the entire duration of the bioaugmentation program

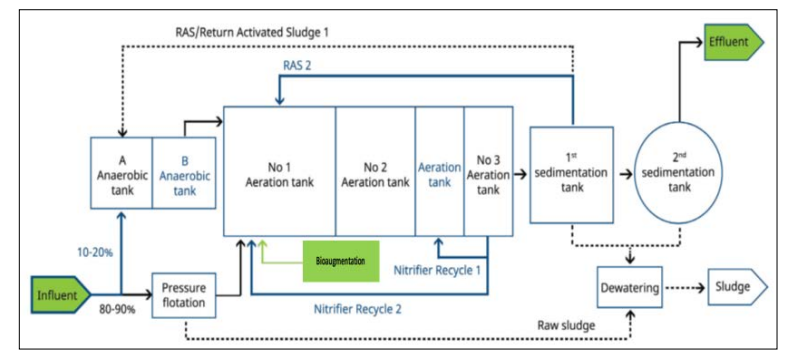

Figure 1: Wastewater Treatment Plant Design

Bioaugmentation technology was drip-fed continuously in the Aeration Tank No.1. Refer to figure 1. The bioaugmentation technology used in this study is a dextrose-based product in powdered form, completely soluble in water. For ease of dosing, the product was mixed with water in a 1000L tote every week and dosed continuously in aeration tank No.1, around the clock.

The findings from the study are showcased through tables and graphs provided below.

| BOD (mg/l) | COD (mg/l) | SS (mg/l) | TN (mg/l) | TP (mg/l) | |

|---|---|---|---|---|---|

| Discharge Limit | 40.0 | 50.0 | 40.0 | 30.0 | 4.0 |

| Initial Value | 105.0 | 156.8 | 124.0 | 103.2 | 7.5 |

| 6 Weeks | 32.1 | 48.8 | 18.0 | 22.1 | 1.5 |

| 10 Weeks | 24.8 | 37.2 | 13.5 | 15.3 | 1.6 |

| Reduction | 76% | 76% | 89% | 85% | 61% |

| Date | BOD (mg/l) | COD (mg/l) | SS (mg/l) | TN (mg/l) | TP (mg/l) |

|---|---|---|---|---|---|

| 1-Apr-15 | 105.00 | 156.80 | 124.00 | 103.20 | 7.50 |

| 20-May-15 | 32.10 | 48.80 | 18.00 | 22.13 | 1.50 |

| 15-Jun-15 | 24.80 | 37.20 | 13.50 | 15.30 | 1.60 |

| 6-Jan-16 | 25.40 | 38.10 | 12.00 | 20.18 | 1.81 |

| 19-Feb-16 | 26.20 | 42.10 | 28.00 | 20.74 | 1.96 |

| 9-Mar-16 | 30.50 | 45.20 | 24.00 | 11.86 | 3.37 |

| 28-Apr-16 | 31.50 | 46.20 | 30.00 | 18.80 | 3.42 |

| 30-May-16 | 30.50 | 42.00 | 25.00 | 13.11 | 2.16 |

| 30-Jun-16 | 32.00 | 44.50 | 32.00 | 15.31 | 3.16 |

| 21-Jul-16 | 26.10 | 47.00 | 10.50 | 14.74 | 2.98 |

| 30-Aug-16 | 27.90 | 46.00 | 12.00 | 13.06 | 3.20 |

| 30-Sep-16 | 29.00 | 47.90 | 18.00 | 23.84 | 2.49 |

| 28-Oct-16 | 34.50 | 48.50 | 16.00 | 26.32 | 2.28 |

| 23-Nov-16 | 16.80 | 31.90 | 6.00 | 10.42 | 0.63 |

| 26-Dec-16 | 26.20 | 44.50 | 33.00 | 25.52 | 2.87 |

| 23-Jan-17 | 21.20 | 39.80 | 28.00 | 28.16 | 0.75 |

| 28-Feb-17 | 18.50 | 35.00 | 32.00 | 20.15 | 1.36 |

| 22-Mar-17 | 16.80 | 31.70 | 18.00 | 10.87 | 2.88 |

| % Reduction | 70.63% | 69.06% | 78.49% | 77.73% | 65.99% |

Figure 6: Graph showing Total phosphorus levels observed less than discharge standards (<4.0ppm)

This South Korean slaughterhouse has been able to maintain effluent compliance standards using Bioaugmentation Technology for more than 2 years now. The study provided a solution to meet stricter discharge limits without the need for plant expansion. Effluent BOD, COD, SS, TN, and TP levels were reduced to be compliant with standards within six weeks of initial Bioaugmentation. This rapid success led to the adoption of Bioaugmentation into the water treatment program of the slaughterhouse. Bioaugmentation Technology has allowed the plant to operate within their discharge requirements and has contributed significantly to plant stability.

Bioaugmentation is an effective long-term treatment solution for improving effluent quality and plant stability. Extended use of Bioaugmentation at this South Korean slaughterhouse led to consistent reductions in effluent BOD, COD, SS, TN, and TP. The implementation of long term Bioaugmentation eliminated the need for proposed plant expansion, resulting in significant capital avoidance.