Author(s): Juhani Pylkkanen

Water is a pure substance that carries a huge load during its natural cycle on the earth, in the bio systems, in washing and cleaning, as well as in agricultural and industrial processes. Water gets rid of the load by evaporation caused by solar heat, and leaves it in the ponds, lakes and seas. In spite of modern waste water treatment these dumps of the water cycle become worse, and energy and chemicals consumption of the treatment has increased steadily. The waters and eco systems suffer increasing amount of drug and pharmaceutical residues, nutrients, various poisons, many other chemicals and micro plastics. Further, the natural water cycle functions as a major climate cooling element together with the photosynthesis. A lot of evaporation cool has lost by extension of civilization, open area building and construction, and underground sewerage systems.

A new integrated water clarification method and device named OxTube for various water matrices and recycling is presented here. The clarification is hermetic and consists of four seamless phases; (1) separation of dissolved ingredients, (2) molecular activation, (3) clarification reactions, and (4) replacement dissolving. It separates dissolved gases like radon, carbon dioxide, hydrogen sulfide and hydrocarbon, and dissolved solids like iron, manganese, calcium, fluorine and phosphorus. The molecules are activated and clarification reactions happen immediately by suction or feed of clean air, oxygen or ozone. The clarified water is aerated or oxygenated right after the clarification. All this happens within a second or few seconds depending on water volumes to be clarified. The integrated clarification is based on the fact that water itself is pure, it just picks up and transfers’ easily heavy load. The treated water can be recycled and discharged in to nature with full nature respect. The treated water can be led to the natural water cycle by spraying it on ground and plants for solar vaporization which means climate cooling, and load of the oceans can be reduced significantly.

Health and wellness impacts of clean air can be dissolved in to the water such a way that exchange of slag and air gas between bio systems and the water initiates immediately in wet contact. Comparable iron gets rusted right away in this treated water but it could take years in dry air.

Present water treatments need a new perspective and environmental respect. In the present water cycle the seas and oceans are rubbish dumps. Rain and waste waters with their load are led or pumped thousands of kilometers as fast as possible in to the huge rubbish dumps through the huge underground sewer network. Climate cooling by water evaporation is reduced significantly. Water and ingredients recycling is little. Present technologies and increasing power consumption in waste water treatment create unsatisfied results. Further, the sewer network causes serious floods. Many serious problems, disasters, awful smell and serious microbe growth can be avoided by the water clarification and wide area water buffers with solar evaporation. Water and natural water cycle are necessary for the bio systems as well as the climate balance.

Water is a pure substance that carries a huge load during its natural cycle on the earth, in the bio systems, in washing and cleaning, as well as in agricultural an industrial process. Water gets rid ofthe load by evaporation caused by solar heat, and leaves it in the ponds, lakes and seas. In spite of modern waste water treatment these dumps of the water cycle become worse, and energy and chemicals consumption of the treatment has increased steadily. The waters and eco systems suffer increasing amount of drug and pharmaceutical residues, nutrients, various poisons, many other chemicals and micro plastics. Further, the natural water cycle functions as a major climate cooling element together with the photosynthesis. A lot of evaporation cool has lost by extension of civilization, open area building and construction, and underground sewerage systems.

OxTube Integrated water clarification process, design criteria, related devices, some practical case studies and combined treatment processes are presented here. The clarification consists of four seamless treatment phases and as the fifth step a firm gas bubble generation in the flow as follows:

There have been and are still the following guiding principles on the development and related research:

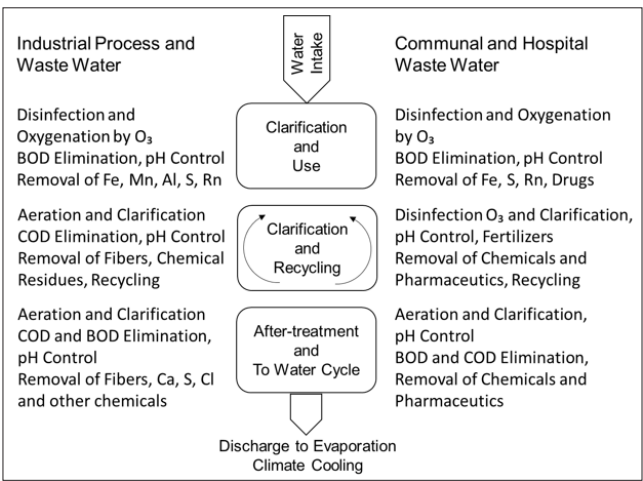

Figure 1 summarizes the development principles. The Integrated Clarification fulfils these development and design principles in several areas but it needs further development and research in many challenging applications. Separation of dissolved ingredients functions well but to remove these is challenging in certain substances like chlorine and salt.

Figure 1: Water Recycling Integrated in to the Natural Water Cycle. There are Several Recycling and Evaporation Systems. Water Picks up Heavy Load that is to be Released Where Caused and There are Only Two Acceptable Options – Recycling or Evaporation to the Water Cycle [1-3].

The new hermetic water treatment process called OxTube and some of its applications are presented briefly here. Focus is set on water purification, waste water clarification, recycling and impact transfer via water in wet contact. However, the integrated clarification is suitable for treatment of all the kinds of water matrices. OxTube Machine presented in Chapter 3 is the basic water treatment device and module that can be modified easily for various tasks, water matrices and installations, and it fulfils the guiding development principles set in Chapter 1 which is the most important. Further, experiences on high impact transfer of the treated water on to biologic tissues in wet contact are presented briefly.

In order to clarify water all, the way the following main criteria are identified:

The following solutions of several alternatives were developed after analysis and test runs:

The channels are designed such a way there is no discontinuities that might cause disturbances in the clarification and dirt sticking in the nozzle. The losses are minimized.

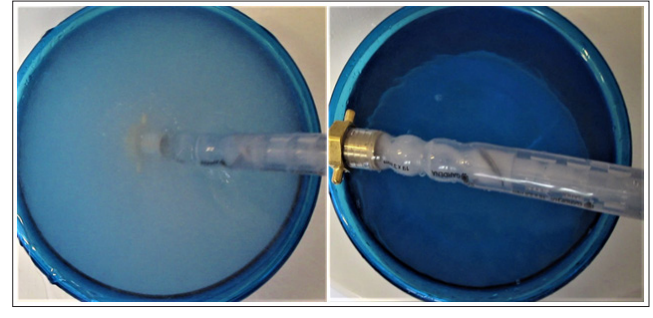

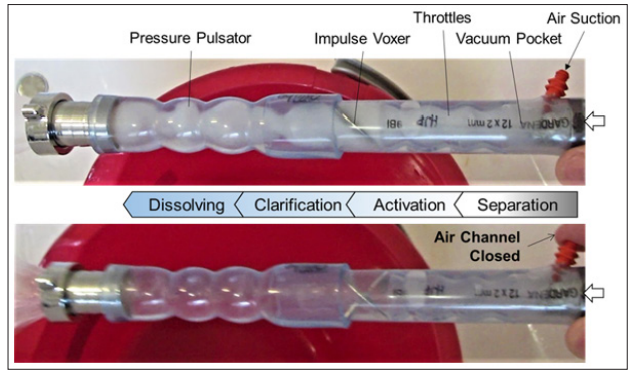

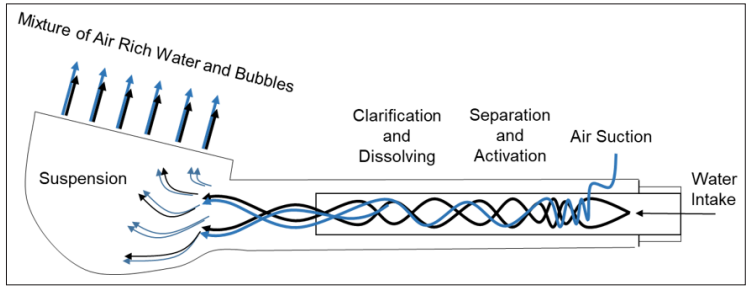

The vacuum pocket sucks gases and possible chemicals, and mixes them effectively and evenly in the water flow. Figure 3 and 4 illustrate the effective suction and even mixing. The mixture of water and air is evenly foggy as it can be seen in Figures 2 and 3. Spray of the mixture of water and air is firm and coherent as it can be seen in Figure 4. Air suction is great, it can be over ten times higher in volume than the water flow, and the gravity decreases respectively. No additional energy is needed.

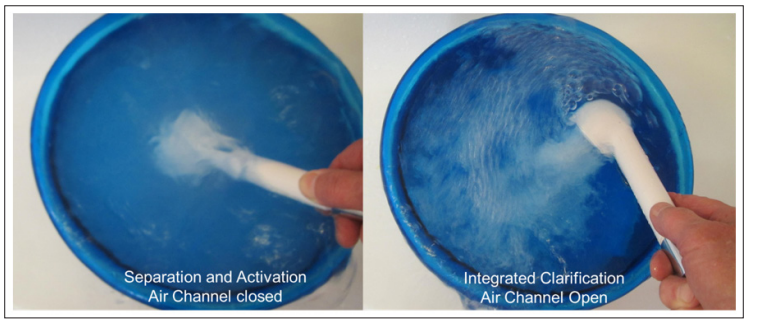

Figure 2: Efficiency of Oxtube Integrated Clarification with Air; Left Swiss Alpen Tap Water When Only the Soluble Ingredients Separation and Molecular Activation Performed, Right the Integrated Clarification at the Same Condition. The Separation, Activation, Clarification and Replacement Dissolving are Performed Seamlessly Within a Second in OxTube [1,2,4].

Figure 3: OxTube Integrated Water Clarification Illustrated Visually with Air Suction. The Integrated Clarification is Performed within Less than a Second [1,2,4].

Figure 4: Performance Of Oxtube Integrated Clarification in Gas Suction and Mixing as Well in Clarification and Replacement Dissolving is Great and Efficient. No Additional Energy is Needed in The Integrated Clarification. Height of the Mixture is Nine Times Higher than the Plain Water has in The Exact Same Condition of Water Intake [1]. Energy Consumption of Fountains is Reduced to One Third.

OxTube Machine is the key module in the integrated clarification with low power consumption. The treatment doesn’t need any additional energy, but side processes like ozone and chemicals generation and feed might need power. Some solutions installed in pressurized piping might need compressed air. However, this is possible to avoid by the system design.

OxTube Machine performs seamlessly all the clarification phases described in Chapter 1 and illustrated in Figure 3.

Bubble generation and mixing with the water is visualized in Figure 4. Height of the outtake spray increases nine times when the air channel is open. Gravity of the mixture turns respectively light in the nozzle. The spray of the mixture stays coherent all the way up which is an essential feature of OxTube Machine. The light gravity mixture of air and water can be sprayed in large area for evaporation cooling.

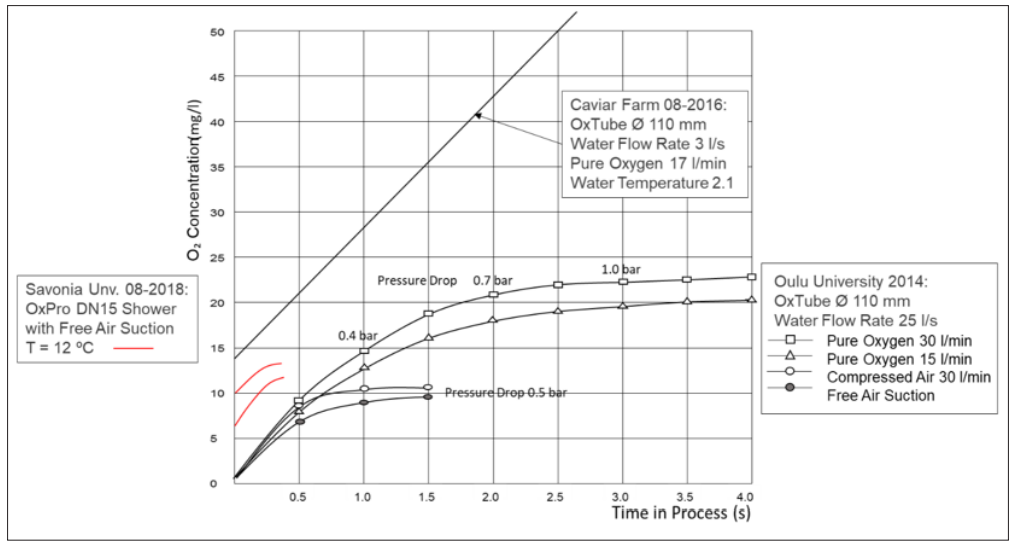

Figure 5 shows the oxygenation efficiency of OxTube Machine at early-stage development [5]. Since 2016 separation of dissolved ingredients has improved and gas suction increased by factor of 5.Losses are measured today in terms of mass flow due to huge gravity drop and change from incompressible to compressible liquid in the nozzle zone. The mass flow losses are measured to be less than 2 percent.

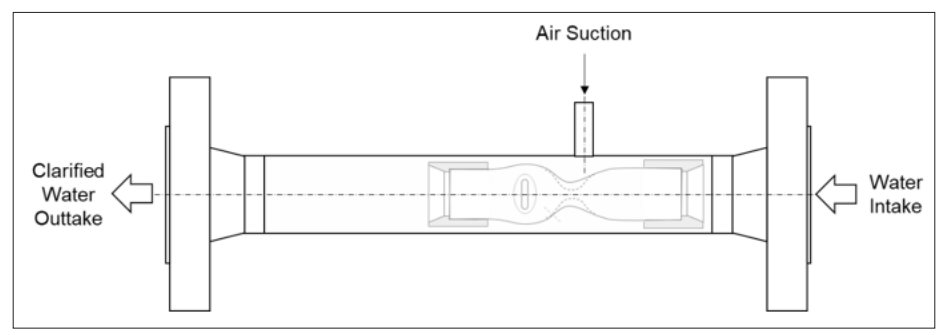

OxTube Machine is presented in Figure 6. It consists of DuOx Nozzle, suspension chamber, air suction nipple, outer tube and fitting flanges. In the small sizes the flanges are replaced by standard thread fittings. All the fittings are metal-to-metal tight fits, there are no individual seals at all. Welding is minimized, only the flanges have to be welded to the outer tube. The structure is very compact and easy to keep clean.

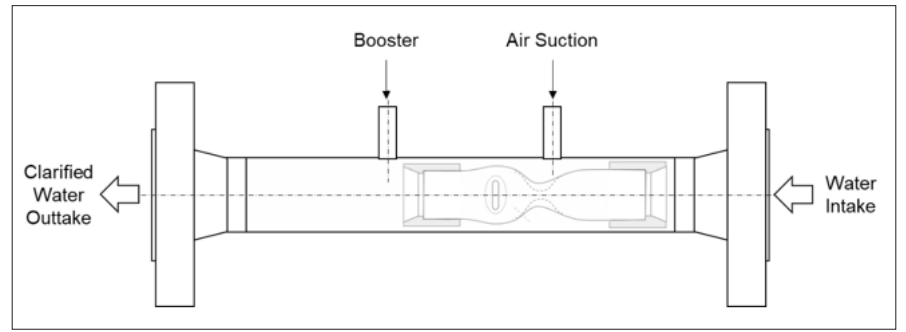

OxTube Machine is easy to modify and optimize for various water matrices and treatments in one. Figure 7 shows the Machine modified to realize heavy gas removal and water clarification in one. There is a booster nipple for pressured air feed that removes separated heavy gases like radon and carbon oxide.

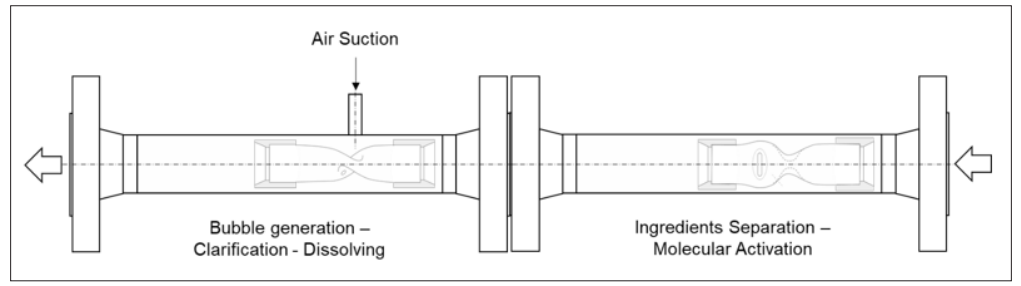

Two OxTube Machines in serial would combine so that the first one performs separation and activation, and the second one clarification, dissolving and bubble generation, Figure 8 Clarification performance is improved particularly in very challenging cases. Further, a booster can be applied in the second machine when heavy gases are involved in the integrated clarification.

There are many other possibilities to figure various combinations of the same modules in order to create the best and fastest solution to meet environmental and economical requirements. Clarification, disinfection and oxygenation of a water matrix can be combined in one OxTube Machine by ozone or mixture of ozone and air feed. The growing environmental problems, microbe variation and growth, and drug residues, are eliminated at the same time with water clarification.

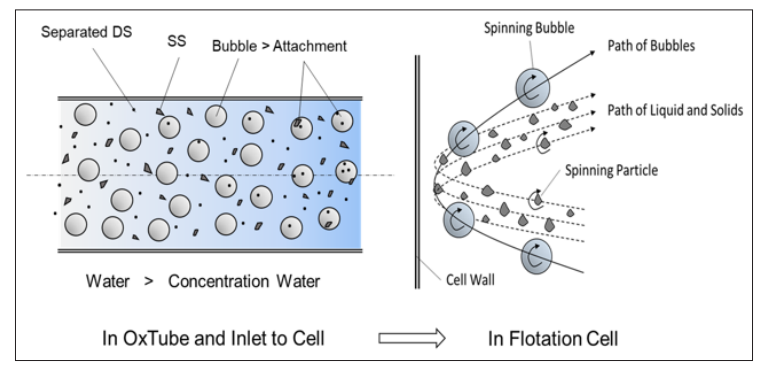

OxTube Machine separates dissolved ingredients but to remove them from the mixture needs further attention. As said OxTube Machine generates huge number of overdosed bubbles by gas suction and clarification reactions which can be used for flotation (Figure 12 and 13). Collision probability of particles and bubbles is high and attachment is identified to be good, so the flotation is a natural way of particle removal, it’s a build-in feature of OxTube Machine. Particle attachment happens in OxTube Machine and Fitting Modules before the flotation cell, and efficiency is improved all over. All the filtering methods can be applied in particle removal after the separation and clarification.

Figure 5: Oxygenation Efficiency of OxTube Machine in Early-Stage Development [5]

Figure 6: OxTube Machine with Gas and Chemicals Suction is Compact Including Standard Fittings. It can be Installed in Various Water Treatment Systems. Pressure Norm is up to PN40 [1,2].

Figure 9 shows the efficiency of the integrated clarification according to a hundred real test runs completed with an industrial waste water. Turbidity of the clarified waste water turned to 0.0 NTU within retention of 30 minute. Only OxTube Machine, a pump and an open outtake vessel were used, no filters. The treated water was identified recyclable for industrial purposes. In order to recycle it for household purposes an ozone disinfection and sand filtering, and related verifications are needed.

Figure 7: OxTube Machine with Suction and Booster Nipple. The Module is the Same as in Figure 6 added by Booster Nipple [1].

Figure 8: Combination of two OxTube Machine, The First One in Line is Responsible for Dissolved Ingredients Separation and Molecular Activation, and the Second One Bubble Generation, Clarification and Replacement Dissolving [1,2].

Figure 9: OxTube Test Runs of an Industrial Waste Water Resulted Turbidity of 0.0 NTU. The Clarified Water is Recyclable in Industrial Process Use [1-3].

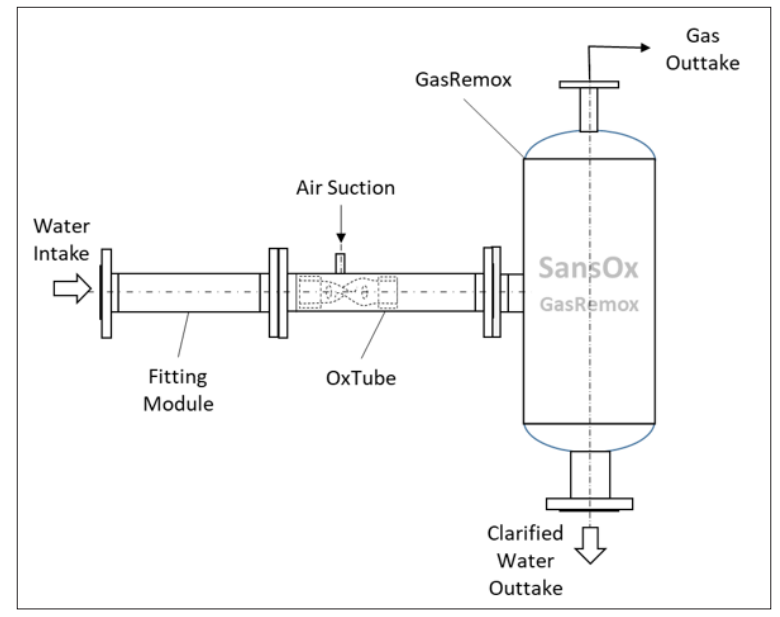

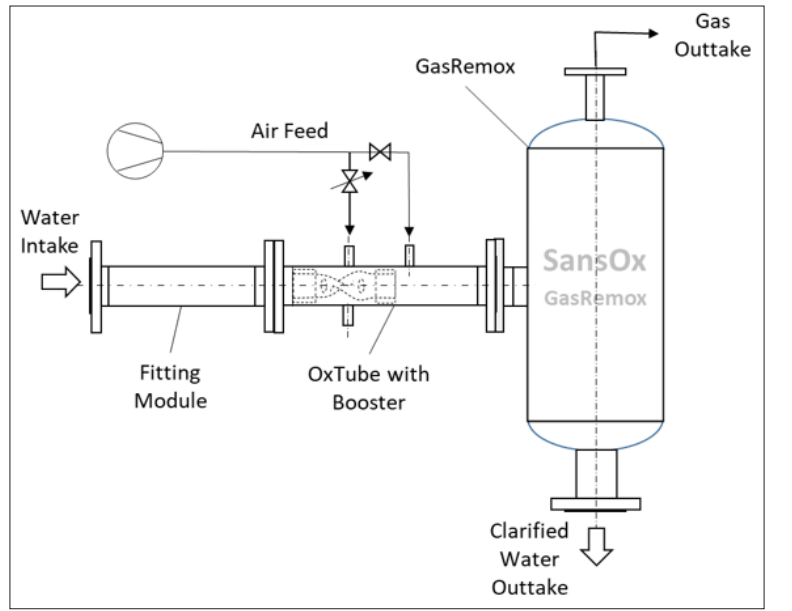

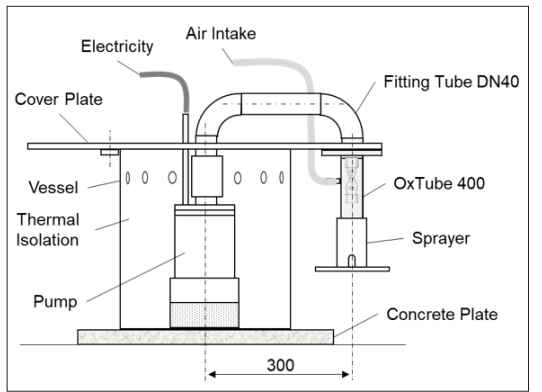

There are many ways and combinations to apply the integrated water clarification technology and removal of separated water load. The basic Water Treatment Unit called WTU is presented in Figure 10. It consists of OxTube Machine, gas removal by GasRemox and Fitting Module. It is developed for industrial process waters, intake water from lakes and groundwater wells, and pre-treated communal waste waters. All kinds of OxTube Machines and modular combinations can be applied in WTU. Only the most challenging water clarification cases are presented here.

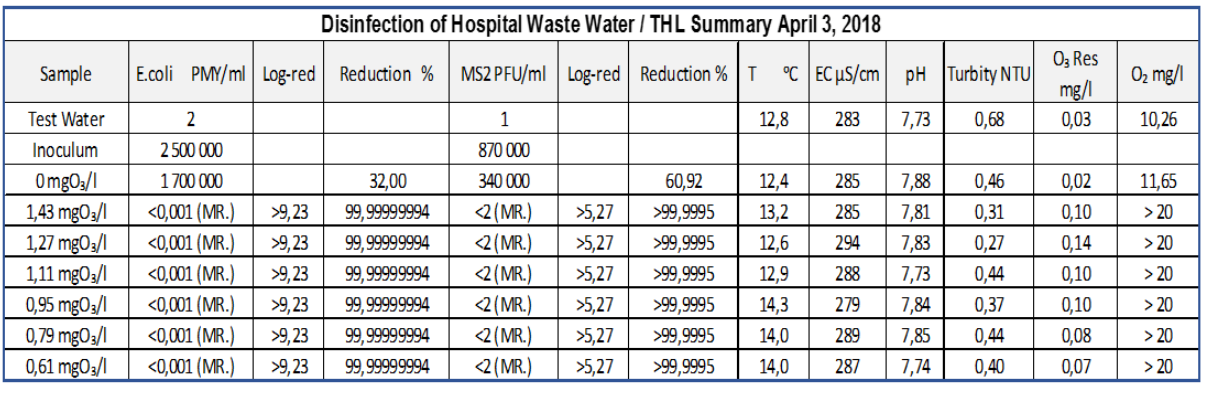

Disinfection of various water matrices including communal and hospital waste water can be disinfected by feeding ozone instead of air. Table 1 presents results in the case of disinfection of a hospital waste water. Microbe reduction of 100 percent was achieved together with clarification and oxygenation of over 20 mgO2/l. Ozone residues were measured negligible.

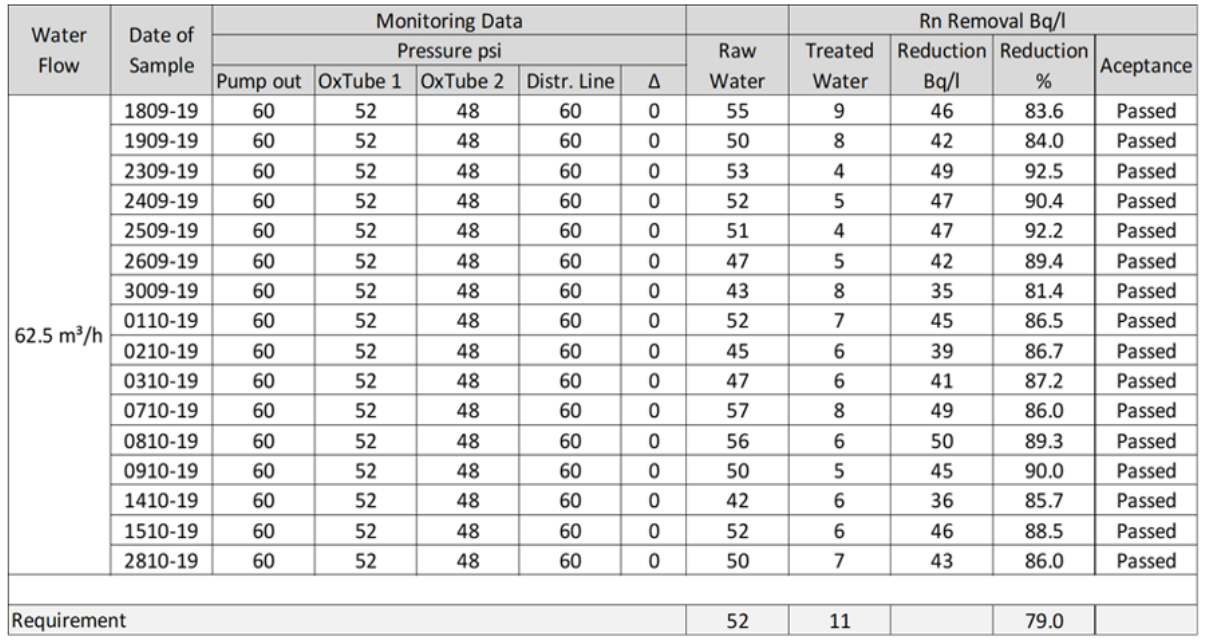

Heavy gas removal facility is presented in Figure 11. It is applied in radon gas removal in intake of ground water. Performance of the Rn removal can be seen in Table 2. In this case two WTU facilities with a compressor were installed in the present ground water intake after the pump. The intake water is clarified and aerated at the same time with Rn removal.

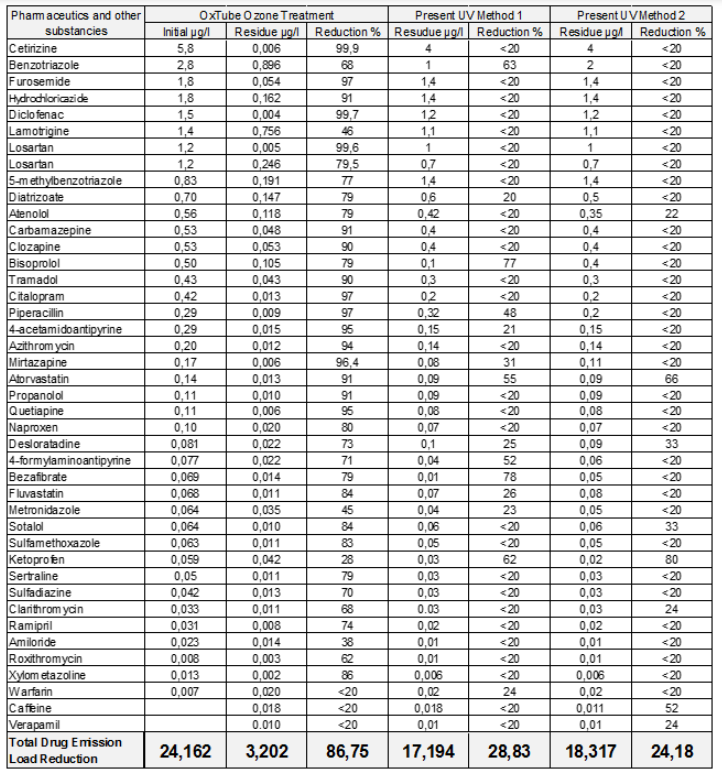

OxTube efficiency in removal of residues of pharmaceutics and some chemicals from a city waste water is presented in Table 3 including comparison to two present systems. Pharmaceutical and drug residues are a fast-growing disaster in natural waters and ground. About 90 percent of these residues were split, clarified and removed only by one run through OxTube Machine to an open vessel without any filters. Two runs result 99 percent reduction. The city waste water was clarified and oxygenated at the same time with removal of the drug residues. The present waste water purification systems separate only 1/4 of OxTube performance. There are many chemicals used decades and led in to the nature and food chains like DDT, aldrin, chlordane, chloroform, bromoform and hexachlorobenzene. The present treatment systems are not able to eliminate these hazardous chemical residues.

Figure 10: Water Treatment Unit for the Most of Water Integrated Clarification Cases. It Consists of Oxtube Machine, Gas Removal Gasremox and Fitting Module. Microbe Reduction Of 60 Percent Was Achieved with Air Suction And 100 Percent with Ozone Feed [1].

Figure 11: Water Treatment Unit of Heavy Gas like Rn and CO2 Removal. Compressed Air is used in Separation, Heavy Gas Blow- Up and Water Clarification [1,2].

Table 1: Disinfection Efficiency of the Integrated Water Clarification of OxTube: 100 % Reduction of E. coli and MS2 achieved with O3 feed of 2 l/min within 0.7 second, Oxygen Concentration Raised over MR 20 mgO2/l, no Significant Ozone Residues / Savonia University of Applied Sciences in Kuopio [6]

Table 2: Radon Gas Removal by Two WTUs with Compressed Air and Boosters from A Ground Water Intake. The WTU Concept is Presented in Figure 11 [1].

Table 3: Removal of Pharmaceutics and Some Other Substances from the Purified City Waste Water of Kuopio Finland with OxTube Integrated Clarification Treatment within a Second. Complex Molecular Structures of the Pharmaceutics Are Split in Separation Phase Before Activation and Clarification [4, 6].

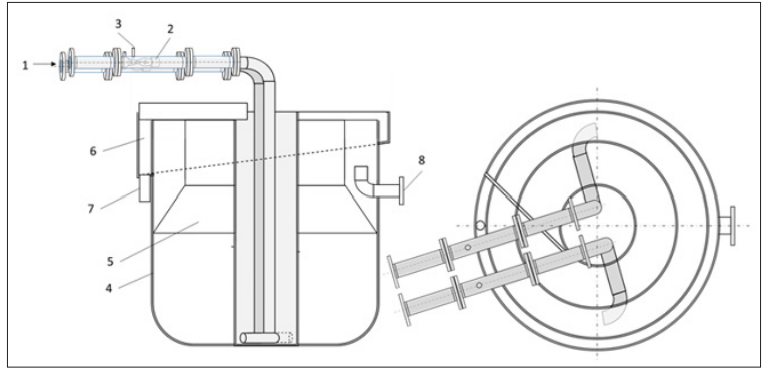

OxTube Machine can be integrated in flotation systems like VoxFlot as shown in Figure 13. OxTube Machine generates a lot of bubbles and even mixture of water and bubbles in the hermetic tube condition as illustrated in Figure 12. Meeting probability of particles and bubbles is high, and particle attachment happens already in OxTube and the following tubes before the flotation cell [4,7,8]. Two head vortex flow of water and bubble mixture is generated in VoxFlot flotation cell that improves particle attachment and extents bubbles path to surface. The Bubble Trap speeds the vortex flow and push out a foam with particles on to the water surface. The clarified water is taken out behind the bubble trap where no bubbles nor particles exist.

Water clarification, disinfection, oxygenation and particle removal by flotation can be combined by feeding ozone or mixture of ozone and air through the OxTube Machine.

The bubble flow through OxTube Machine and two head vortex flow decrease the unit size significantly compared to a straight flow flotation with diffusers. Chemicals feed if necessary is completed directly in OxTube Machine. Further, there are no rotational components involved. These features means reduced capital and operational costs [8].

Figure 12: OxTube Machine Generates Bubbles and Even Mixture in The Hermetic Tube Condition. Meeting Probability of Particles and Bubbles is High, and Particle Attachment Happens already in OxTube and the Following Tubes Before the Flotation Cell [1,4,7].

Figure 13: VoxFlot Combined Clarification, Disinfection and Flotation; 1. Water Intake, 2. OxTube Water Clarification, Disinfection and Bubble Generation 3. Gas Intake, 4. Flotation Cell, 5. Bubble Trap, 6. Foam Collector, 7. Foam Outtake, 8. Clarified and Disinfected Water Outtake. The Gas Fed is Ozone or a Mixture of Air and Ozone. VoxFlot is Presented in References [1,4,7,8].

Natural waters are more or less waste water sumps already today. Rivers, channels, dikes and drainpipes function as drains of the nature water cycle. Ponds, lakes and seas function as sewage basins. Pollution load of waters has increased and became more hazardous particularly in population centers where the water and rain are led fast to drains and sewage basins of the water cycle. Energy consumption of waste water treatment has increased significantly but it is deficient. Evaporation is reduced tragically which means significant loss of climate cooling power, more floods and increased desert area. It’s urgent to refresh waters and food chains.

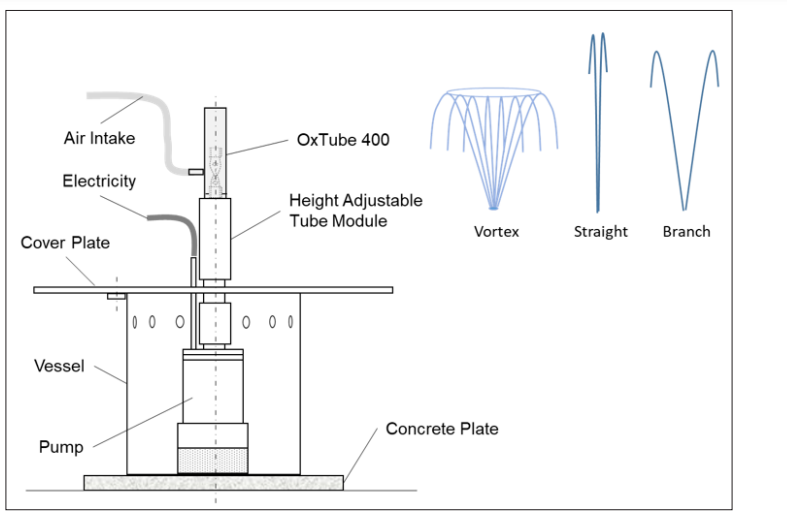

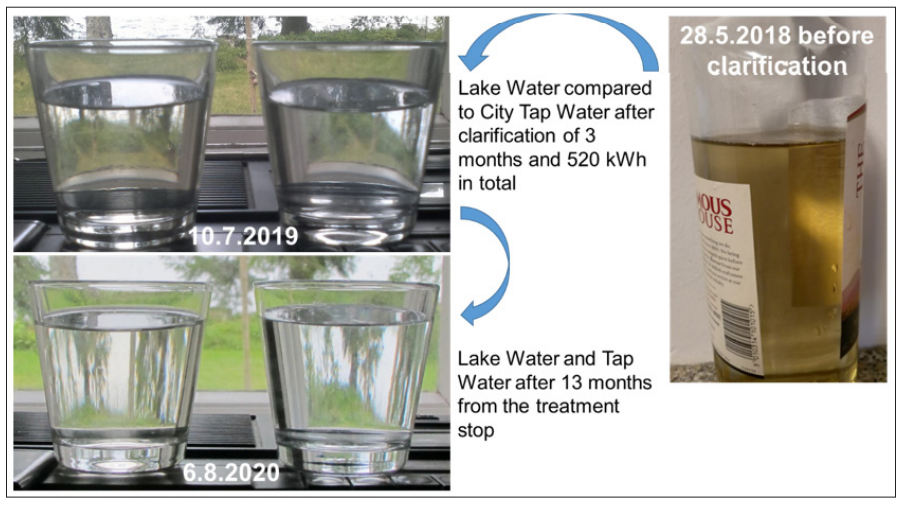

The OxTube Machine and its integrated water clarification presented in Chapter 3 can be utilized easily many ways and positions of the water cycle. Two examples are presented in Figures 14 and 15 just giving an idea how easy it could be. Water Clarifier has all the functions of OxTube Machine. The combined water clarifier and fountain performs integrated water clarification and landscaping by water spray. Both of the examples are easy to install and movable. Their energy consumption is found negligible. Figure 16 shows clarification of a lake of 2.3 km² with a small clarifier ClariOx shown in Figure 14.

Figure 14: Water Clarifier ClariOx Refreshes Waters by Clean Air without Chemicals. Energy Consumption is Little [1,2]

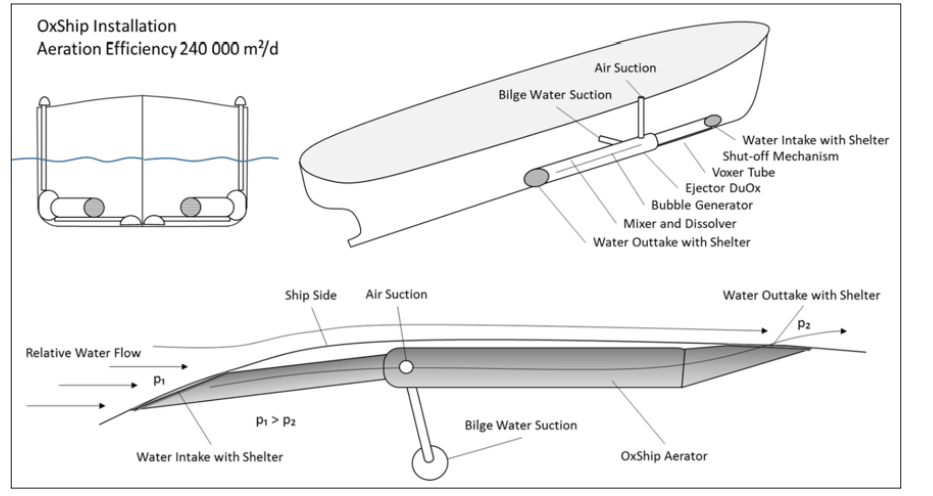

Further, the integrated water clarification can be applied in all kinds of water transport vehicles without any additional energy consumption. Kinetic energy of the vehicles in motion can be used for the treatment. Flow resistance can be kept the same or even reduced by proper design. A ship would clarify sea water in depth of 4-meter 240 000 cubic meter a day. Figure 17 shows an integrated ship installation.

Figure 15: Combined Water Clarification and Fountain [1,2]

Figure 16: Clarification of a Lake Of 4.5 Km Long And 0.5 Km Wide. Water Became Clear, and Plants and Food Chains Recovered

Figure 17: OxShip Installation. A Cruising Ship can Clarify Sea Water of 240 000 m³/d in Depth of 4 m. Without Additional Fuel Consumption [2]

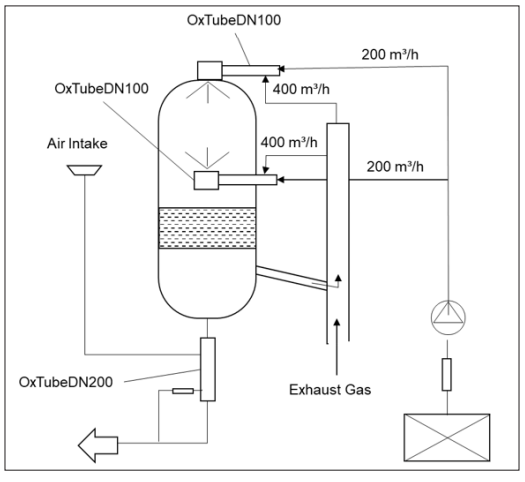

OxTube Machine can suck and mix gases in the water stream over ten times of water in volume NTP. Exhaust gases can be sucked and mixed in water of flowing tube condition, and sprayed for collection and recycling. Figure 18 presents an exhaust gas washing and collection system for ships that can be engine based. The system can be scaled down to small ships and boats, and even to trucks and cars. The water can be clarified and recycled back to the washer or to the sea water clarification by OxShip presented in Figure 17.

Figure 18: OxTube Sucks and Mixes Exhaust in the Water Stream by Forming a Foggy Mixture in the Hermetic Tube Condition

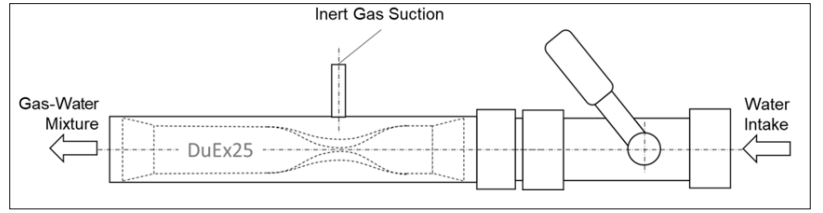

DuEx Nozzle is modified from DuOx of Oxtube for fire hydrants, and it can be integrated in extinguishing syringes as shown in Figure 19. It sucks and mixes gases over ten times of water in volume. Gases could be air, or an inert gas like nitrogen, CO? or the fire smoke. DuEx Nozzle generates a coherent mixture of gas and water as shown in Figure 4. Energy and water consumption can be reduced significantly with air suction, and further, extinguishing efficiency improved with an inert gas suction or feed. Suction of the fire smoke can be utilized.

Figure 19: Extinguishing Syringe with DuEx Nozzle. The Inert Gas Could Be Co2, N2 or The Fire Smoke. Water and Energy Consumption are to be less Compared to Present Extinguishing Syringes.

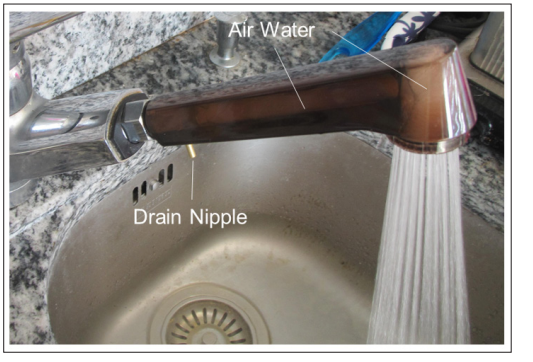

OxPro down scaled from OxTube treats the water in flowing condition in its hermetic tube. It splits molecular and ionic structures, activates and separates soluble ingredients in the water, and replaces these by air gases that are sucked by vacuum in the nozzle zone. Figures 20a and 20b illustrate the four phase treatment of OxPro. The water is clarified and air gas dissolved in OxPro Tap and Shower hand set. Further, lot of air bubbles are generated and mixed in the water flow.

Health and wellness impacts of the OxPro treated water are discussed briefly in reference [3]. Over 500 individuals and professionals have been used so far OxPro treated Water for various tissue deceases and orally in order to improve metabolism. The treated Water transfers impacts of clean air immediately in to tissues like skin, nails and hair, and orally to metabolism in the wet contact. Further, surface tension of the water treated is reduced which enhances the interaction between the water and bio tissues. Naturally, substances in general can be dissolved in the water such a way that improves the interaction and impact transfer. DuOx Nozzle can be integrated easily in various devices like in shower and tap devices as shown in Figures 20a 20b, and 21. A movable kitchen tap is presented in Figure 22.

The OxPro treated water was mixed-in in a fish aquarium about one third of its volume. In couple of days the fishes turned brighter in color and more social in behavior, and further, algae disappeared and plant leaves turned from dark brown to green. It’s said, plain tap water would kill fishes.

Figure 20a: Demonstration of OxPro Tap with Swiss Household Water. Separation of Dissolved Ingredients and Molecular Activation without Air Suction on the Right, and Integrated Clarification on the Left. OxPro Tap is shown in the Middle

Figure 20b: Demonstration of OxPro Shower. Separation of Dissolved Ingredients and Molecular Activation without Air Suction on the Left, and Integrated Clarification on the Right

Figure 21: OxPro Machine can be Integrated in Hand and Over-Head Shower Devices. The Water is Clarified, Air gases Dissolved in it and a Smooth Spray of Air Bubbles and Water Generated

Figure 22: OxPro Kitchen Tap

OxTube Integrated Water Clarification is found to meet the environmental and economic guiding principles and criteria listed in Chapter 1. It has been applied successfully in removal of pharmaceutics, radon gas, calcium, manganese and iron from various water matrices, and disinfection with ozone of a hospital waste water. More than 40 different pharmaceutical residues in total over 24 µg/l were removed 90 percent by OxTube Machine with Integrated Clarification within a second in one through run [6]. Radon removal from 57 to 8 Bq/l is achieved continuously in five installations of ground water intakes at Water Plants. Disinfection of a hospital waste water with ozone resulted 100 percent microbe reduction, and clarification and oxygenation of the waste water at the same time. Reduction of viruses of 60 percent was achieved just by air suction without any other gas and chemicals feed. Two runs with air might result about 80 percent reduction. Microbe growth and variation is reduced with just clean air suction and eliminated with ozone feed [9].

OxTube Machine and Water Treatment Unit can be installed in various positions in present treatment processes and facilities of various water matrices. It can be applied in pre-treatment, removal of the water load, clarification and oxygenation and disinfection of various waste water matrices. Further, discharge water can be treated with the environment respect.

The four phase clarification and bubble generation of OxTube Machine can be applied in all the areas of water purification and recycling described in Figure 1. Volumes of 0.1 to 600 m³/h with one OxTube Installation can be clarified and returned to the natural water cycle with full environment respect. OxTube Machine can be integrated in and combined with present water systems. The DuOx nozzle can be integrated in hydro turbines combined power generation and water treatment. Combined fountain and water treatment by integration of DuOx Nozzle reduces energy consumption in to half or more and the nature loves it according to fountain tests completed. DuOx Nozzle improves fire extinguishing, saves water and reduces damages by feed of an inert gas like nitrogen and carbon dioxide, or smoke from the fire (see Figures 4 and 19). Irrigation and fertilizing can be combined by means of exact spot farming. The integrated clarification should be started at all the water intakes already due to fact that waters content already too much waste, drug residues, radon and micro plastics. Seas and oceans - refuse dumps of the water cycle - can be refreshed by integrating OxTube Machines in ship structures. A cruising ship can treat sea water of 240 000 cubic meter a day without additional fuel consumption. There are more opportunities to be solved by water treatment in respect of the nature.

During the research and test runs in product development the clarified water was found a bit slippery and its surface tension reduced. It has a significant impact on skin, hair and nails, and taste and mouth hygiene as well. Further, eczemas and various wounds recovered fast without additional medical care, and signs of metabolism improvement was reported by people and professionals involved in test runs. Pure air and water have certain health features, and mixing and dissolving these deeply together the healthy impacts and transfer speed are multiplied in wet contact.