Author(s): Warlito M Galita* and Wenceslao M Valerio

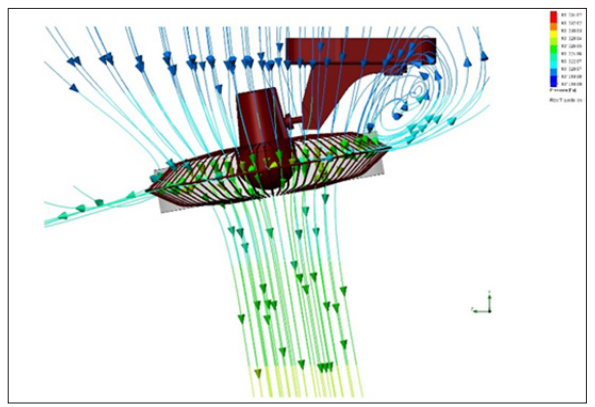

The major objective of the study was to design and develop a motion activated and temperature-controlled electric fan. It is the most practical and affordable way of keeping areas cool especially during hot and humid months. In the Bulacan State University, many electric fans installed in lecture rooms are left unattended even after class hours. This translates to unnecessary fire risks and/or excessive electric consumption of the University. It is in this light that the researchers developed a device that presents an opportunity for the development of intelligent appliances that can save on electricity consumption due to its innovative and eco-friendly features. Various designs were put forward and a careful consideration of each plan was done, with special considerations to the need for innovative appliances that can be very useful in terms of energy efficiency and environment-friendliness through an integrated multi-dimensional sensor system.

The study utilized the developmental research method in the fabrication of the project. The focus on the procedures and processes involved analysis, development and evaluation of the project and in validating the project. The steps involved in this method include the following: (1) studying research findings pertinent to the project; (2) developing the project based on the findings; (3) field testing of the project, and (4) revising the project.

The project was developed in sixty (60) working days, where prototypes were subjected to a dry run and simulation period of two (2) weeks continuous operation. The actual operation cycles of the prototypes in accordance with the varying room temperatures throughout the day was also observed during this period, testing them on a varied number of parameters, namely: operation time, turn on times in terms of fan speed control mode and motion sensitivity tests.

Evaluation results revealed that the project functioned according to its lofty expectations where it was determined that it was the appropriate design that integrated the most practical and adaptable configuration for the intended application. It is in this line that intelligent or smart ventilation systems have now matured, providing a cost-effective approach to managing hot and humid conditions.

Over the past decades, the world has seen an unprecedented rise of energy consumption. All over the world, vast amounts of energy are being consumed due to the fast pace of industrialization happening today. It is for this reason that governments around the world have institutionalized energy conservation programs in their respective constituencies.

Energy conservation is the reduction or removal of unnecessary or unwanted energy use. Energy conservation plays a significant role of lessening climate change. It helps the replacement of non-renewable resources with renewable energy. Energy conservation is often the most inexpensive solution to energy shortages, and it is more environmentally kind alternative to increased energy production.

In the Philippines alone, energy conservation has been the mantra among various government agencies. This why Republic Act 11285, otherwise known as the “Energy Efficiency and Conservation” is a law institutionalizing energy efficiency and conservation, enhancing the efficient use of energy, and granting incentives to energy efficiency and conservation projects. This Act aims to guide the Philippines in building an energy-efficient nation, and in making energy efficiency and conservation a way of life for all Filipinos. Energy efficiency will advance the country’s economic development and help ensure energy security, optimal energy pricing and sustainable energy systems.

It is in this light that each individual is enjoined to lend a helping hand in energy conservation. In fact, one of the key strategies to promote efficient energy use in the countries all over the world is to implement the minimum energy performance standards (MEPS) with emphasis on Space Cooling and Refrigeration [1].

MEPS is a specification, containing a number of performance requirements for an energy-using device, that effectively limits the maximum amount of energy that may be consumed by a product in performing a specified task. It is usually made mandatory by a government energy efficiency body especially for various types of office and home appliances.

One popular appliance that ensures cooling in the dwelling place of most Filipino households is the electric fan. It is the most practical and affordable way of keeping the house cool especially during hot and humid months. Even in schools, electric fans are commonly found to ventilate the premises and keep students comfortable during their stay in the classrooms.

Conventional electric fans nowadays come in different shapes and sizes. They come in many colors and features and even some with timers. However, one important function that has been always overlooked in the design of an electric fan is the motion and temperature sensor that can automatically turn on and off, depending on the presence of people inside the premises.

In the Bulacan State University (BulSU) for instance, many electric fans installed in lecture rooms are left unattended even after class hours. This translates to a hazardous scenario wherein overloading of the electric lines due to overheating may occur and may lead to unnecessary fire risks and/or excessive electric consumption of the University.

If the BulSU aims to achieve the goal of a sustainable and energy- efficient campus, one of the crucial steps is the implementation of smart technologies that will minimize or mitigate electricity consumption.

It is in this light that the researchers developed a device that will present an opportunity for intelligent appliances that can save on electricity consumption due to its innovative and eco-friendly features.

Energy consumption behavior can be defined as the total energy use of the occupant from both human and physical characteristics. It can be safely said that buildings or classrooms themselves do not use electricity, but the people occupying them [2].

This is in consonance with the previous findings that universities’ increased energy consumption are a function of the electricity usage and lifestyle behavior of its students as the main contributory factors. Such a relatively uncontrolled phenomenon has contributed to a situation of energy wastage among the students [2-5].

Although the subject of energy conservation has been studied before, various trends in energy consumption studies has shifted towards creating a high level of awareness among researchers regarding the global warming problem and to devise various ways and means to reduce energy consumption. It is in this line that this research was conceptualized to be able to address the rising cost of energy in view of the dwindling supply of fossil fuels that is used to generate electricity.

In the Philippines and in most hot and humid countries, the electric fan is one of the most popular electrical appliances due to its cost effectiveness and low power consumption advantages. In fact, according to Vijay it is a common appliance available today and widely used in many applications. It is also one of the most sensible solutions to offer a comfortable and energy efficient. In fact, the fan has been long used and still available in the market. However, conventional electric fans use manual switches to control speed manually [6-7].

Due to changes in climate and other similar fields, many researches focused on automatic temperature control system application in various applications. For example, Johnson developed an automatic temperature controller for multi-element array hyperthermia systems, along with multi-loop automatic temperature control system design for fluid dynamics. Its automatic temperature control for transport airplanes and design of automatic temperature control system on laser diode of erbium-doped fiber source are also being put forward as innovative schemes. Such advances in technology has triggered the development of more advanced control mechanisms to benefit everyday appliances like the electric fan [8].

Roy, et. al. stated that today in the era of Intelligent Systems; a smart fan is very much essential to the concept of “Smart Homes”. They noticed that most circuits developed to tracks the presence of person in a room was using infrared (IR) and passive infrared (PIR) sensors as the tracking sensor. However, performance of IR sensors has traditionally been limited by their poor tolerance to light reflections such as ambient light or bright object colors, while PIR sensors have tolerance problems with temperature limit values [9].

On the other hand, ultrasonic distance sensors do not have gaps in the coverage zone like IR and PIR sensors and overall detection range is comparable to that of a PIR sensor. Thus they developed an ultrasonic sensor electric fan to measure the distance between the human and based on the pre-defined set points that varied the speed of the prototype.

Such advances in technology has triggered the development of more advanced control mechanisms to benefit everyday appliances like to electric fan. In incorporating these aforementioned literature and studies, the researchers came up with an innovative design in the present investigation.

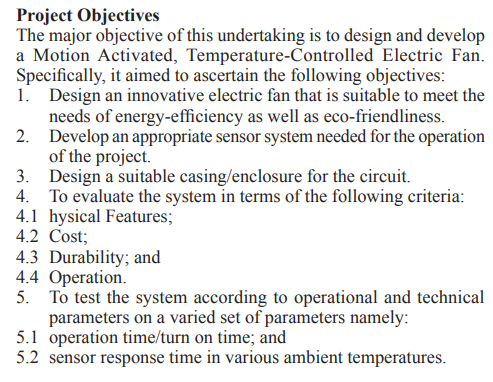

The study was guided by the input, process, and output (IPO) model or framework as shown in Figure 1. The various concepts, related literature, as well as the tools and equipment used in the construction of the project and expenses incurred in the fabrication of the project served as the INPUTS of the study. On the other hand, the project design, sourcing of needed materials, fabrication, field testing and troubleshooting the technical problems served as the PROCESS of the study. Finally, the OUTPUT of the study is the fabricated Motion Activated Temperature Controlled Electric Fan.

Figure 1: Conceptual Model

The study utilized the developmental research method in the fabrication of the project. As Richey and Klein (2005) stated, developmental research tends to systematically build knowledge grounded in data derived from practice. It is a way to launch new procedures, techniques, and tools based upon a precise analysis of specific cases. As such, developmental research can either create generalizable conclusions or statements of law or produce context-specific knowledge that serves a problem-solving function that enhances the study’s credibility [10].

The focus on the procedures and processes involved analysis, development and evaluation of the project and in validating the project. The steps involved in this method included the following:

(1) studying research findings pertinent to the project;

(2) developing the project based on the findings;

(3) field testing of the project, and

(4) revising the project.

The step by step fabrication procedure is described as follows: Firstly, all of the needed spare parts and supplies for the project were purchased and prepared immediately. This was followed by the assembly of all the sensor circuit sub-assembly, which is composed of the motion and temperature sensors. After this step, the Arduino board was interconnected with its corresponding LCD bar display and the appropriate wiring connections of the circuit sub-assemblies, will be done. Four (4) relays was included in the wiring of the circuit prior to its connection to the electric fan motor. Correspondingly, the source code or program software will be loaded unto the Arduino microcontroller to complete the assembly of the electronic control circuit.

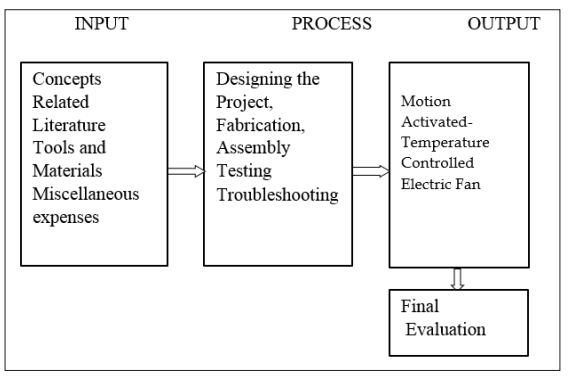

The next procedure was fabricating the suitable chassis needed to enclose and secure all of these circuit sub-assemblies properly in in place. Careful consideration was given to this procedure to ensure that there are no sharp edges and proper mounting and layout of the circuits will be done. After the preparation of the chassis, the actual testing of all the circuit sub-assemblies through an actual dry run of the project will be conducted to ensure its functionality. Figure 2 shows the functional block diagram of the project.

Figure 2: Functional Block Diagram of the Project.

Around sixty (60) working days was consumed in the preparation and fabrication of the project, which is good for the fabrication of three (3) prototype units. The reason for this is for the researchers to facilitate effectively product testing. Upon completion of the project, all prototypes were subjected to a dry run and simulation period of two (2) weeks continuous operation. The actual operation cycles of the units in accordance with the varying room temperatures throughout the day was also observed during this period. An audio-video presentation in time-lapse form was prepared as a documentation procedure of the actual demonstration of the operation of the prototypes.

The prototypes was tested on a varied number of parameters, namely: operation time, turn on times in terms of fan speed control mode and motion sensitivity test.

To test its operation time, the prototypes were tested for a period of one (1) week continuous operation. The various malfunctions or glitches observed were noted and documented. The testing of its fan speed control mode were done to limit the fan speed automatically based on the ambient temperature conditions inside the classroom. The following technical parameters as shown in the Table 1 below:

|

Speed Setting |

Actual Activation Temperature (In Degrees Celsius) |

Running Time |

|

1 |

24-25 |

0 |

|

2 |

26-27 |

2hr 7mins |

|

3 |

28-29 |

5.2 mins |

|

4 |

30 and above |

0 |

Based on the table above, the average running time of the speed setting no. 2, with an actual average temperature of 26-27 °C, is about 2 hours and 7 minutes. While the speed setting of 3 remains open for 5.2 minutes only. The location of the temperature sensor may affect the results of the experiment as it was placed in the middle of the room. Thermal variations between Speed settings 2 and 3 were found, with an average of 12 seconds at intermittent intervals. These glitches in the speed-temperature setting were possibly attributed to the wind turbulence between the fan and the ceiling. That may be the repeatability and sensitivity of the thermal sensor used. Furthermore, its technical performance and reliability of speed-temperature set-up are adaptable to any weather conditions.

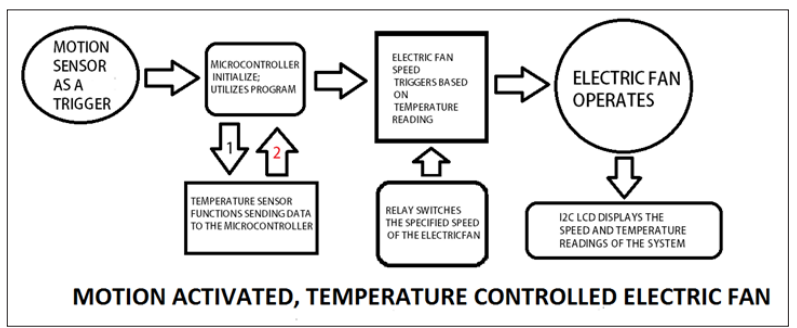

To investigate the source of temperature fluctuation, the researchers used computer aided simulation using the Flow Simulation software. It was found that the turbulence was made in between the fan’s mounting, ceiling and the fan’s housing, as shown in Figure 3.

Figure 3: Flow Simulation of air movement across a fan

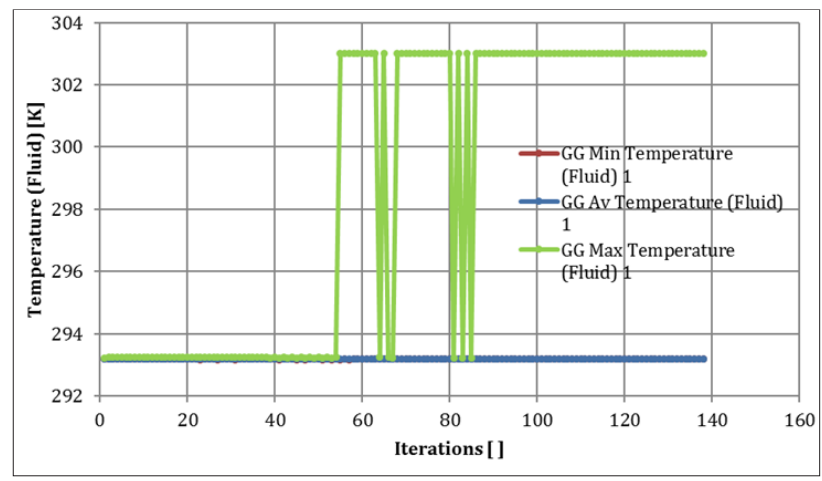

Meanwhile, the variation of temperatures likewise were simulated with a minimum temperature of 20.18°C (293.18°K) and a maximum temperature of 30°C (303°K) at the set nominal fan speed of 10 rad/s (600 rpm). These data was recorded by the software and plotted in a diagram with respect with the number of iterations, as shown in Graph 1.

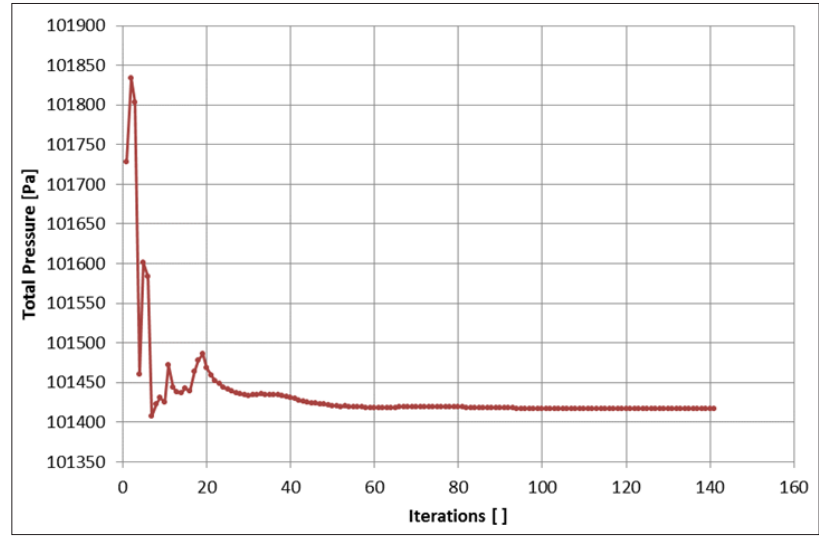

Graph 1: Shows the simulated minimum and maximum temperature of air flowing in fan With the maximum total pressure of 101,416.6325 Pa, the data was plotted using the said software and is shown in Graph 2. The pressure dramatically dropped by 0.369 Pa before it crosses to fan blades, which has minimal effect in the temperature of air flow.

Graph 2: Total Pressure recorded with the number of iterations Thus, it can be concluded that the location of temperature sensor greatly affects the accuracy of its reading. With the aid of flow simulation, it is easier to understand the air flow within the fan’s surrounding and the sensor can be placed with minimal or without the turbulence.

On the other hand, the motion sensor’s sensitivity will be undertaken by utilizing individuals that will be entering the room in various aspects. Various distances between the subject and the motion sensor were tested to observe its response time. Three experiments were performed to ensure that any technical fluctuations or glitches were recorded. In this set-up, the subject was required to move in front of the motion sensor at a distance of 0.25, 0.5, 0.75, and 1 meter, respectively. It was observed that the system has a delay with an average of 2.583 seconds and a distance of 0.25 meters has the fastest response time. On the other hand, for a one-meter setting, the delay reached 5 seconds. it is also important to locate the motion sensor to a maximum detection of 0.75 meters. It should not exceed the recommended distance to ensure that further delay in the operation may not occur. Table 2 summarizes the various conditions that were observed in testing the project.

|

Trials |

Distance From Sensor (Meters) |

Response Time (S) |

|

1 |

0.25 Meter |

2 |

|

2 |

2 |

|

|

3 |

2 |

|

|

1 |

0.5 Meter |

3 |

|

2 |

3 |

|

|

3 |

2 |

|

|

1 |

0.75 Meter |

2 |

|

2 |

3 |

|

|

3 |

2 |

|

|

1 |

1 Meter |

5 |

|

2 |

3 |

|

|

3 |

2 |

After testing the prototypes on a varied number of parameters aforementioned, an objective evaluation was undertaken by the researchers to test its acceptability and performance in terms of the pre-determined criteria set forth in the conceptualization of the study. Shown in Table 3 is a 5-point Likert scale that was used to quantify responses of the evaluators, with 5 being the highest and 1 being the lowest [11].

|

Scale |

Verbal Interpretation |

|

4.21-5.00 |

Highly Acceptable |

|

3.41-4.20 |

Very Acceptable |

|

2.61-3.40 |

Moderately |

|

|

Acceptable |

|

1.81 – 2.60 |

Unacceptable |

|

1.00 – 1.80 |

Highly Unacceptable |

|

|

Unacceptable |

Summary of Findings

As reflected in Table 4, all evaluation criteria set forth at the outset of the study were given favorable ratings of “Very Acceptable” by the panel of evaluators in terms of (1) Physical Features (Mean=4.75); (2) Cost (Mean=4.47); (3) Durability (Mean=4.70) and (4) Operation (Mean=4.75).

|

Criteria |

Mean |

Interpretation |

|

1. Physical Features |

4.75 |

Highly Acceptable |

|

2. Cost |

4.47 |

Highly Acceptable |

|

3. Durability |

4.70 |

Highly Acceptable |

|

4. Operation |

4.75 |

Highly Acceptable |

|

Overall mean |

4.67 |

Highly Acceptable |

In addition, it was determined that it was the appropriate design that integrated a practical and adaptable design for a wide variety of applications. Finally, the project also functioned according to expectations, with the electric fan being able to respond appropriately wiht the various changes in temperature and detected motions.

On the basis of the findings of the study, it was determined that it was the appropriate design that integrated a practical and adaptable design for a wide variety of applications. Finally, the project also functioned according to expectations, with the motion and temperature sensing was easily monitored with the use of this device. The response of the device to the varying levels of of stimuli translated to appropriate adjustments in the electric fan speed as initially set out in the study, underscoring the importance of smart sensing technologies that are both cost effective and energy efficient. All in all, the project was evaluated by the panel of experts as “Highly Acceptable”.

In light of the significant findings derived from the development of this project, the following are the recommendations: