Author(s): A Marangoni

The competitiveness of plastic pipes vs. non plastic pipes for water and sewer networks relies on both a superior performance to cost ratio and environmental benefits that can be offered to the utility industry, across the whole lifecycle of these networks. In order to help the European pipe network owners in selecting most cost-efficient pipe materials, lifecycle cost data comparing PVC-U vs. non plastic pipe materials have been regularly generated and updated since the late 2000’s. These data have been generated using the Total Cost of Ownership (TCO) tool, an analysis meant to uncover all the lifetime costs that follow from owning certain kinds of assets. These analyses consider the costs to purchase pipes, install, operate, maintain and dismantle the pipeline. Significant benefits have been evidenced for PVC-U in both the water and the sewer networks. The analyses have demonstrated that the removal and landfilling of PVC-U pipes after use is a significant TCO contributor. The cost benefits of PVC pipe recycling vs. other end of life scenarios (landfilling, incineration) have been estimated in monetary terms, using the Cost Benefit Analysis (CBA) methodology defined by the OECD, and applied on PVC pipes used in water and sewer networks in Germany and Italy.

The utility sector is a pillar of the economic system in many countries, providing basic services both to citizens and enterprises. Plastics pipes are key elements driving the technical and environmental performance of water and sewer networks. The competitiveness of plastic pipes vs. non plastic pipes relies on both a superior performance to cost ratio and environmental benefits that can be offered to the utility industry, across the whole lifecycle of these networks.

Up to date lifecycle cost calculations across the whole lifecycle of the water and sewer pipe networks are critical to help the owners to make informed decisions in selecting pipe material. Lifecycle cost data comparing PVC vs. non plastic pipe materials have been regularly generated and regularly updated in Germany and Italy since the late 2000’s, using the Total Cost of Ownership (TCO) tool [1].

Managing the end of life of pipes has become increasingly strategic and the recyclability of the pipe material has become a key decision factor for the European utilities. Several studies have shown that PVC-U material stabilised with a Ca-Zn stabiliser, could be mechanically recycled up to 8 times without losing their performances [2]. The amount of pipes & fittings recycled in the VinylPlus® framework, reached 82,344 tons in 2020 [3]. The evaluation whether to recycle a product should consider several technical, financial as well as environmental elements. The Cost- Benefit Analysis (CBA) methodology defined by the OECD has been found to be able to evaluate the balance between many of these elements for the recycling of PVC pipes [4].

CBA: Cost-Benefit Analysis

Ci,y : Sum of all direct and indirect costs incurred during year y for life cycle stage i

DI: Ductile Iron

DR: Nominal Discount Rate

IR: Inflation Rate

GRP: Glass-fiber Reinforced Plastic

LCSi : Life Cycle Stage i

PV(LCSi): Present Value of the costs of Life Cycle Stage i

TCO: Total Cost of Ownership

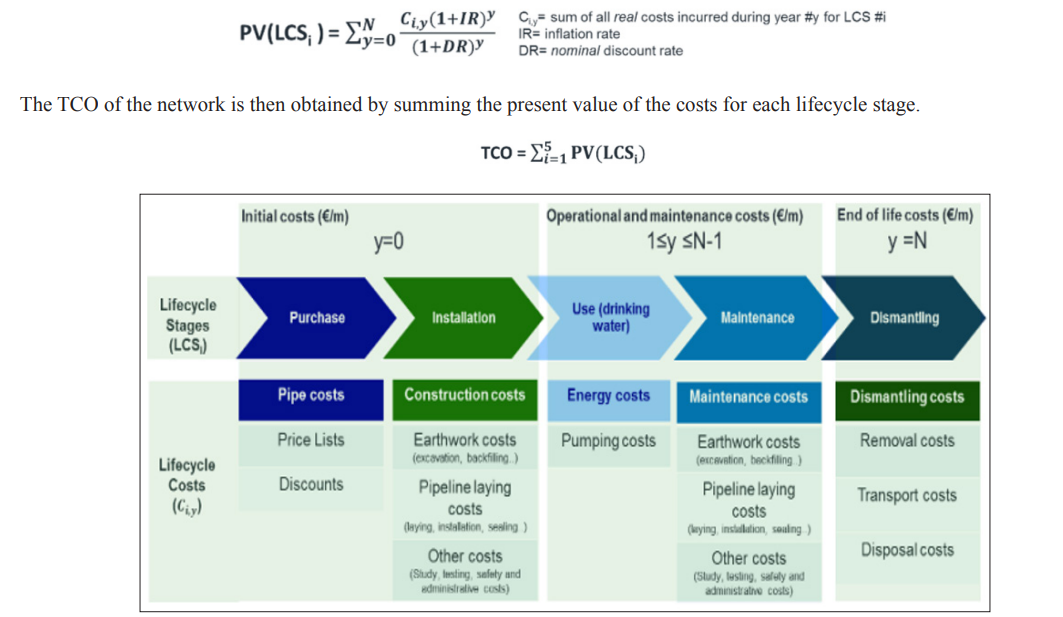

The TCO of an infrastructure asset, like a pipe network, is calculated by collecting all the direct and indirect costs incurred by an owner over the entire life cycle of the asset. A quantitative cost model has been developed with 5 life cycle stages (LCSi) as shown in Figure 1.

The Purchase and Installation stages cover the first year of the asset (year 0). The Use and Maintenance stages cover the service life of the network from year 1 to year N-1. This model assumes that the pipe network will have to be substituted at the end of its service life. A dismantling stage covering the removal of the old pipe, the transport of old pipe to disposal location and the landfilling of old pipe, has also been defined (year N). For each of these stages, a set of direct and indirect costs (Ci,y) in €/meter of network (€/m) have been defined. A present value (PV) of the costs for each life cycle stage i (PV(LCSi)), is computed by summing the future costs, adjusted for inflation (inflation rate= 1.5%) and discounted at an annual rate with a nominal discount rate taken as the Weighted Average Cost of Capital (WACC) of the network owner (1% in Germany, 3% in Italy).

The TCO of the network is then obtained by summing the present value of the costs for each lifecycle stage.

Figure 1: Quantitative Life Cycle Cost Model

Pipe costs have been determined by consulting price lists obtained from pipe manufacturers and engineering consultancies. The typical discount rates applied for pipes in Italy and Germany have been accounted for. For construction costs incurred during the installation stage, average cost rates were rigorously determined for each of the earthwork, pipeline laying and overhead operations. Field cost studies based on tender specifications and interviews with installers were carried out for each of these operations. Significant discrepancies were observed for these averages depending on the site location (urban vs. rural), type of paving or local regulation. Installation costs include dismantling and disposing of old pipes. Energy costs of the operational stage of the water networks were determined using the hydraulic analysis published in 2017 by the PVC Pipe Association [5].

Average annual energy consumptions were determined and converted into energy costs by using national energy prices. The maintenance costs that were taken into consideration for the water and sewer networks exclusively refer to the repairs needed after failure. Annual maintenance costs were estimated by multiplying the estimated cost for one repair by an annual failure rate. Average annual failure rates were estimated for each material covered in this study based on available data from the Utah State survey, as well as data for water and sewer networks available in Italy and Germany [6-8]. Due to a lack of data, the failure rate for GRP was assumed to be the same as for PVC-U. The repair costs in

Italy and Germany were estimated using the same methodology as for the installation. Some costs rates, like those related to the earthworks, are typically higher because of the shorter sections processed.

TCOs were calculated in Italy and Germany for a range of pipe diameters (63 to 315 mm for the water networks, 250 to 630 mm for the sewer networks) and pipe materials typically used in the existing networks of these countries. For the water networks, PVC-U was compared to Ductile Iron (DI) in both countries and, in Italy, to Glass-fiber Reinforced Plastic (GRP) as this material is increasingly used there for larger diameter pipes. For the sewer networks, PVC-U was compared to concrete and clay in both countries and to 3-layer PVC-U in Germany. 3-layer pipes with an inner solid layer of recycled PVC-U are increasingly used in Germany. A wide range of dig-up reports prove that a service life of over 100 years is feasible for PVC-U pipes, therefore a service life of 100 years was adopted as a baseline scenario for the water networks [9]. A service life of 50 years was selected for the sewer networks.

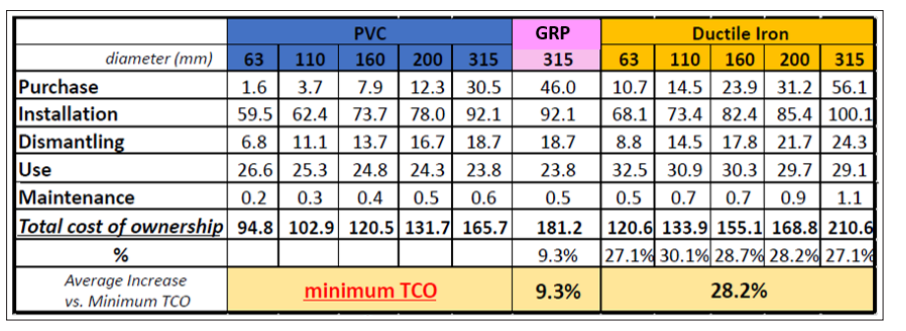

For the Italian water networks, the TCO results from Table 1 show that GRP and DI pipes are, by averaging across the different diameters, 9.3% and 28.2% more expensive, respectively.

Table 1: Total Cost of Ownership (TCO) estimates for Italian water networks made of homogeneous PVC, Glass-Fiber Reinforced Plastic (GRP) and Ductile Iron Pipes

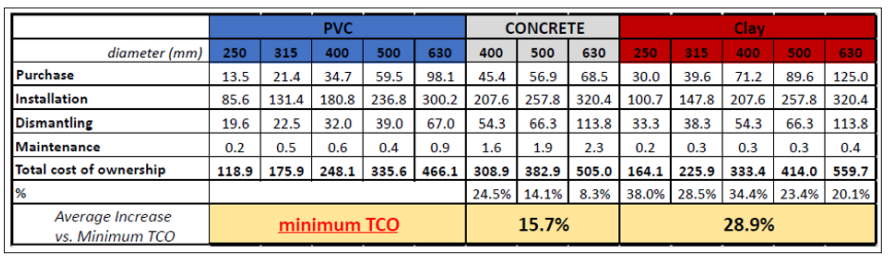

For the Italian sewer networks, the results from Table 2 show that concrete is on average 15.7% more expensive; clay is 28.9% more expensive.

Table 2: Total Cost of Ownership (TCO) estimates for Italian sewer networks made of homogeneous PVC, Concrete and Clay Pipes.

From Table 1 and Table 2, it can be concluded that main cost contribution is from the installation. This cost is, on average, 57% in water networks and 68% in sewer ones. Material costs represent for the water pipes from 2-3% up to 27% of the TCO, depending on the pipe material. For small diameter PVC-U water pipes, this contribution is negligible (< 2%). For sewage networks, the weight of material cost is higher than drinking water (10%-20%) due to bigger diameters and higher technical requirements (e.g. resistance to corrosion). Dismantling costs are account for 10-20% of the TCO.

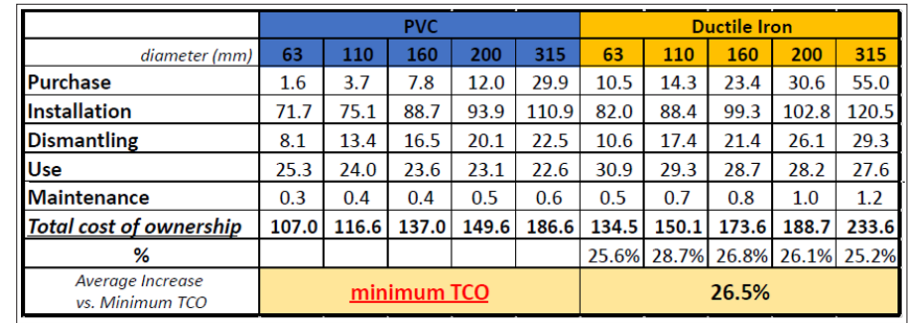

For the German water networks, the TCO results from Table 3 show that DI is, on average, 26.5% more costly.

Table 3: Total Cost of Ownership (TCO) estimates for German water networks made of homogeneous PVC and Ductile Iron Pipes

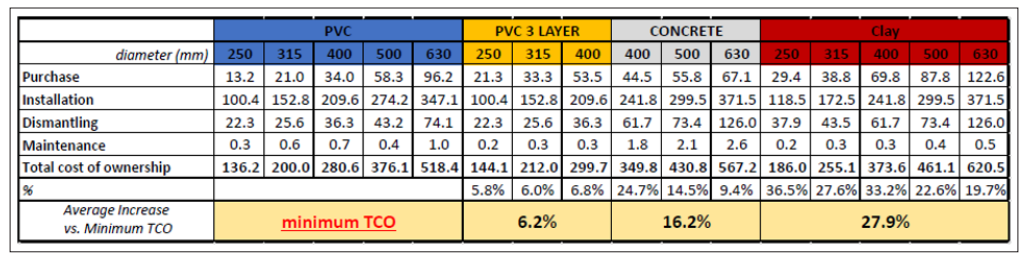

In the German sewer networks, Table 4 shows that cement and clay are, on average, 16.2% and 27.9% more expensive, respectively.

Table 4: Total Cost of Ownership (TCO) estimates for German sewer networks made of homogeneous PVC, 3layer PVC, Concrete and Clay Pipes

Installation contributes, on average, to 56% of the TCO in the water networks and 68% in the sewage ones. For water pipes in Germany, materials contribution ranges from 1.5% of TCO up to 24%, as diameter grows. Dismantling costs account for 10-20% of the TCO.

As removal and landfilling of the pipes at the end of the service life have been shown to be important TCO contributor, cost-benefit analyses (CBA) have been performed to compare landfilling with other end of life management scenarios, such as recycling and incineration.

The CBA approach allows to examine the direct and indirect impacts of a project for the community as a whole. The CBA aims to verify that the costs incurred for a project are lower than the corresponding benefits. The analysis is based on the comparison of different scenarios of carrying on (or not) a project. For the purposes of this study, the CBA examines the direct and indirect impacts of PVC pipes recycling vs. other end of life scenarios. The impacts considered are both economic as well as environmental.

On one hand, the CBA considers the costs of recovering, separating and treating PVC pipes at their end of life. On the other hand, the study accounts for the pipe waste disposal savings, the value of the recovered pipe material, the carbon emission savings, the positive economic and employment fall-outs from the recycling business. For the financial items, the study takes into account costs (or missed benefits) as well as benefits (or avoided costs) of PVC pipes recycling. For the environmental features, the investigation carries out a monetary evaluation both of environmental costs (or missed benefits) and of the benefits (or avoided costs) allowed by the recycling process.

The analyses have been done for Italy and Germany, considering country-specific peculiarities, in terms of adopted products, financial figures, as well as specific waste management practices. Analyses have been done in Italy and Germany on homogeneous PVC-U pipes, an on 3-layer PVC-U pipes in Germany. 1 ton of PVC-U pipe is assumed as the functional unit; this allows to conduct CBA analyses independently from the pipe diameter. The items expressed in different units of measure have been parametrized according to the functional unit. Two different scenarios are compared for the end of life of pipes: recycling vs. incineration for Germany and Italy, recycling vs. landfill for Italy. All costs-benefits balances assume an adequate territorial coverage for the PVC pipes collection and recycling sites. An increase in the distance could reduce the net benefit of recycling, even if it will remain positive.

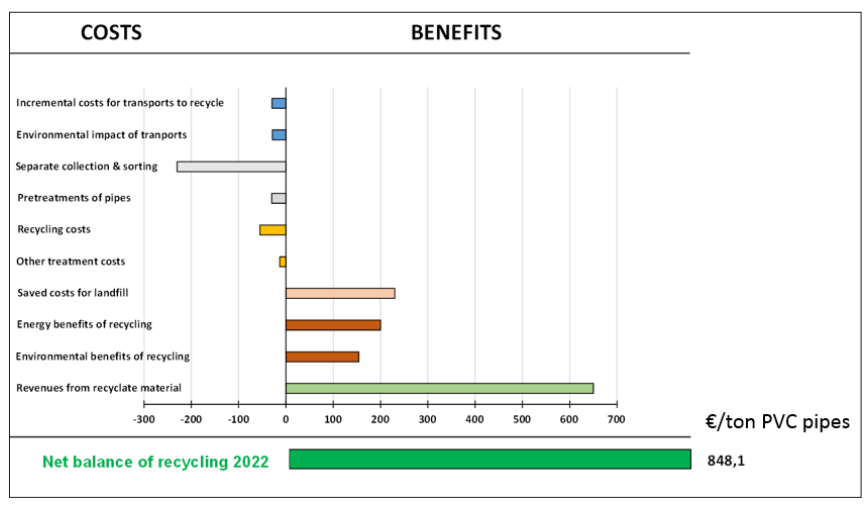

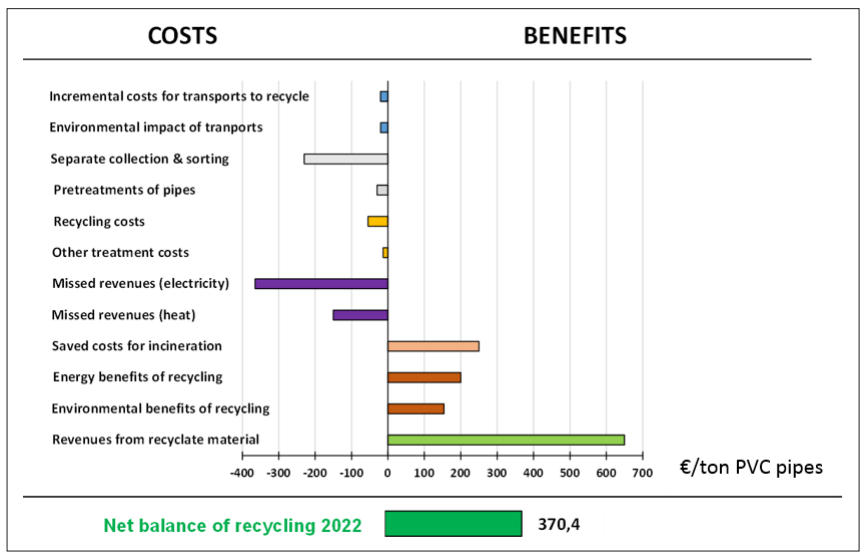

Figures 2 and 3 show the results of the cost-benefit analyses comparing, respectively, recycling vs. landfilling, and recycling vs. incineration for homogeneous PVC-U pipes. Recycling in both cases shows a net positive balance. The net benefits for recycling vs. landfilling are in the range of 850 € per ton of pipe.

Figure 2: CBA for Homogeneous PVC-U Pipes in Italy: Recycling vs. Landfilling

Figure 3: CBA for Homogeneous PVC-U Pipes in Italy: Recycling vs. Incineration

The net benefits for recycling vs. landfilling are greater than recycling vs. incineration due to the energy recovered (electricity and heat) during incineration.

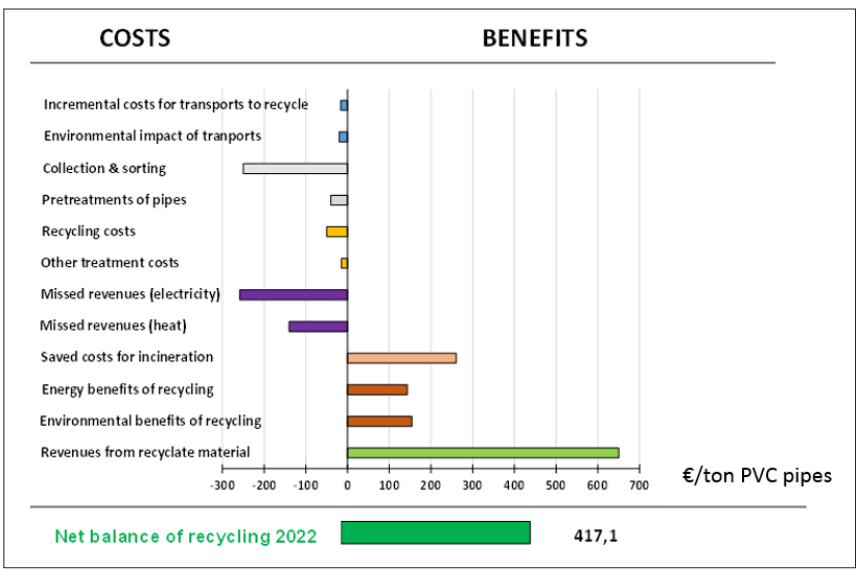

For Germany, only one alternative scenario is considered; recycling is compared to incineration. The reason for this choice is the ban in this country of the landfilling of wastes. Materials with high caloric value have to be pre-treated, recycled or incinerated with energy recovery.

Figure 4 shows the CBA results for homogeneous pipes show that the net balance of PVC recycling vs. incineration is also positive in Germany.

Figure 5 for 3-layer pipes show a slight reduction in the net benefit vs. the homogeneous pipes. Reason is that these pipes contain an inner layer of previously recycled PVC, whose market value is lower.

Figure 4: CBA for Homogeneous PVC-U Pipes in Germany: Recycling vs. Incineration

Figure 5: CBA for 3-layer PVC-U Pipes in Germany: Recycling vs. Incineration

In all cases considered in the TCO study, the PVC-U pipes are best TCO performer vs other non-plastic materials. The main cost contribution is from the installation. Materials always represent a small share of the TCO. The removal and landfilling of PVC-U pipes after use is a significant TCO contributor.

For all cases considered, the CBA results show a positive net positive balance for PVC pipes recycling vs. landfilling or incineration. In all cases investigated, the revenues from recycled material make up the main benefits. Collection and sorting are the main costs. This result should push for more and more PVC recycling in the pipes industry. On the other hand, utilities active in building and renovating water and sewer network, should take into account the recycling easiness of PVC pipes in their procurement choices. The current discussion about the inclusion of incineration under the EU Emission Trading System could further increase the net benefit of recycling vs. incineration. The dramatic increase of energy prices recently suffered in Europe could affect the estimations but in principle it cannot significantly change the overall evaluation.

The author wishes to thank PVC4Pipes for having financially supported this study and accepted to disclose the results.