Author(s): <p>Laxminarayana Korada* and Satyaveda Somepalli</p>

This paper explores the transformation of proactive maintenance in the power transmission industry through the adoption of 5G technology and drones. Traditional reactive maintenance methods are compared to proactive maintenance strategies, highlighting the benefits of predictive control and constant monitoring enabled by technological advancements. The role of 5G technology in enhancing drone capabilities, enabling real-time data analysis, and supporting predictive maintenance is discussed. Furthermore, the impact of drone technology on safety, efficiency, and cost-effectiveness is analyzed. Integrating 5G and drones for proactive maintenance offers numerous advantages, including enhanced worker safety, accident prevention, cost savings, and optimized resource allocation. Case studies and success stories illustrate the positive impacts of these technologies on operational efficiency, safety, and cost management. However, challenges related to technical, regulatory, data privacy, and security aspects must be addressed for successful implementation. Future trends and innovations in 5G, drone technology, AI, and machine learning are anticipated to significantly enhance predictive maintenance capabilities.

The power transmission industry is highly significant for the delivery of electrical power from the generation point to the consumer. This infrastructure needs to be well sustained to avoid cases of halting services or cases of accidents. The changes in maintenance have been realized with the introduction of 5G technology and drones in proactive maintenance. The following article will shed light on how these technologies are adopted to improve safety, maintain operational continuity, and reduce costs – primarily in remote and high-risk environments.

The change being experienced in the power transmission industry from the historical system of reactive maintenance to proactive maintenance does not merely represent a change of functioning but is in fact an indicator of a change in the strategy. While reactive maintenance can maintain equipment in response to their failure, it causes rises in repair costs, increased safety hazards, and unplanned downtime [1]. While, on the other hand, proactive maintenance is a systematic approach to consistent, scheduled prevention to prevent premature failures. This type of thinking is backed by technology, which makes it possible to have constant monitoring and predictive control thus ensuring a reliable power supply together with reduced disruptions [2].

Traditionally, maintenance techniques have been substantially reactive-oriented in the sense that they attended to failed equipment then embark on rectifying it. Sustaining single points can be expensive and unproductive as unplanned outages are detrimental to the provision of service and can lead to major financial losses [3]. Some of the strategies that have been proposed include the preventive, predictable, and condition-based maintenance strategies seek to address the above problems by solving them using data and analytics to predict equipment failures [3].

Technological advancements like IoT, AI, and smart sensors have been the key enablers for any shift to a predictive maintenance solution. These technologies help in gathering and analyzing large amounts of data which in turn helps the power transmission companies to forecast future problems and plan maintenance activity [4].

Several advantages arise from proactive maintenance. It reduces the probability of the occurrence of unplanned downtimes in the electric power plant hence improving its reliability and availability. It also lengthens the time before main equipment requires a replacement, enhances safety features, optimizes energy usage, and supports sustainable cost reduction in the future [4]. Moreover, since proactive maintenance aids in avoiding equipment failures, it also contributes to minimizing the environmental effects caused by power transmission operations.

A preventative maintenance perspective in the power transmission business cannot be overemphasized. It is an effective strategy that not only provides for the proper functioning of the power plants but also for the sustainable and efficient development of the electric power industry. The role of proactive maintenance will only be more important in the future and maintaining the quality and solidity of the global power systems.

Power transmission line maintenance is a critical task that requires high-speed data transmission and real-time analytics. With the introduction of 5G technology, power transmission companies can now leverage their high-speed, low-latency capabilities to enhance drone performance, enable real-time data analysis, and support predictive maintenance. In this revised content, we will focus on the benefits and applications of 5G technology in power transmission line maintenance.

The integration of 5G technology in drones used for power transmission line maintenance provides several advantages. First, 5G enables high-resolution image and video transmissions, allowing for detailed inspections of power transmission lines. Second, 5G's low latency supports real-time data transmission, providing instant feedback to pilots and maintenance crews. Third, 5G increases drone autonomy, enabling longer flight times and greater distances covered, ultimately improving overall efficiency [5].

5G technology has made significant strides in enabling real-time data analysis for power transmission line maintenance. Its high- speed, low-latency characteristics allow for rapid data transmission between drones and ground stations. As a result, maintenance teams can quickly analyze incoming data, identify potential issues, and initiate corrective action promptly [6]. Additionally, 5G's massive device connectivity feature enables simultaneous data collection from multiple drones, further streamlining the data analysis process.

One of the most promising aspects of 5G technology is its ability to support predictive maintenance. By continuously collecting data from drones and analyzing it in real-time, machine learning algorithms can identify trends, anomalies, and potential failure points. Moreover, 5G's fast data transmission rates accelerate the training of these models, increasing accuracy and reliability. Ultimately, this leads to reduced downtime, lower maintenance costs, and improved power transmission line availability [7].

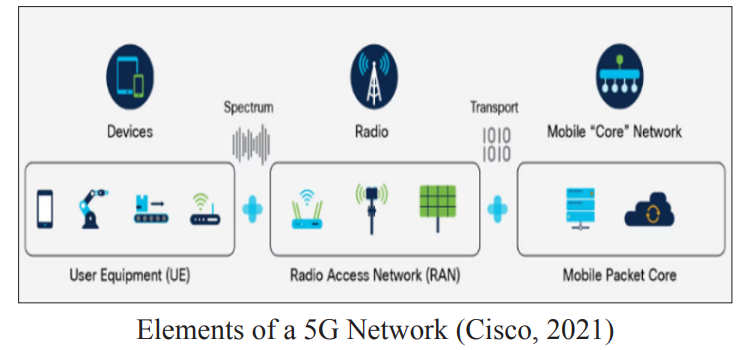

5G technology uses Massive MIMO (Multiple Input Multiple Output), beamforming, and mm-Wave (millimeter wave) frequency bands to achieve its impressive performance levels. Together, these techniques provide increased capacity, coverage, and spectral efficiency, supporting high-speed, low-latency communications required for power transmission line maintenance. For instance, Ericsson's 5G solution architecture comprises three main elements: Radio Access Network (RAN), Transport Network, and Core Network. Each element works together harmoniously to deliver reliable, secure, and high-performance 5G connectivity (Ericsson, n.d.).

By implementing 5G technology, power transmission companies stand to benefit from substantial cost savings and resource optimization. According to a report published by Accenture, utilities leveraging digital technologies like 5G could potentially save $8 billion annually in maintenance costs alone (Accenture, 2017). Furthermore, 5G's ability to support remote monitoring and diagnostics enables field personnel to address emerging issues remotely, reducing travel requirements and associated expenses. Consequently, adopting 5G technology in power transmission line maintenance promises significant improvements in productivity, efficiency, and financial performance.

Drones are progressively becoming essential maintenance equipment in a variety of industries, including power transmission. Drones equipped with sophisticated sensors and high-definition cameras can observe infrastructure from above, making it simpler to analyze transmission lines, towers, and substations. But because it does not require human staff or equipment to physically move across high slopes or over precarious cliffs, this aerial technique is not only quicker and less expensive than the conventional ground- based approaches, but it is also less dangerous [7].

Improved data analysis systems, more resilience and independence, and improved flight control have all been hallmarks of drone advancement in recent years. The drones that are currently in use may fly autonomously next to the transmission line and gather visual data, such as pictures that are essential for identifying wear and tear, corrosion, or any other factor that could cause the system to collapse [8].

Drone utilization reduces the risks of falls and electrical hazards that come with manual inspections. Power companies may do comprehensive and frequent inspections with drones, resulting in better-maintained infrastructure and fewer unplanned outages. Drones can also reach places that human inspectors would find dangerous or inaccessible, guaranteeing a thorough maintenance schedule [8].

Drone inspections are not just safer, more efficient, and cost- effective. They decrease the need for costly and time-consuming scaffolding, cranes, and helicopters. Drone data can be processed to prioritize maintenance chores, optimize resource allocation, and avoid costly emergency repairs [8].

Proactive maintenance in the power transmission business has advanced significantly with the integration of 5G communication with drone technology. 5G's low latency and high-speed data transfer considerably improve drone operations precision by enabling in-depth real-time monitoring and analysis. In order to prevent power outages and ensure the safety of the infrastructure, this synergy is especially useful for performing maintenance tasks like detecting corrosion on metal structures and monitoring vegetation encroachment near power lines [9].

Drones can now send sensor data and high-resolution photos quickly thanks to 5G technology, facilitating quick analysis and decision-making. This capacity is crucial for seeing any problems before they become serious enough to cause equipment failure or service outages. Drones are used in this capacity to lessen the need for labor-intensive and potentially dangerous manual inspections [9].

Drones equipped with 5G networks can conduct predictive analytics, utilizing gathered data to anticipate possible difficulties and plan maintenance before they materialize. Since proactive maintenance can reduce downtime and increase the lifespan of power transmission equipment, it is more effective than reactive maintenance.

There are several obstacles to maintenance in isolated and difficult- to-reach locations, ranging from logistical problems to the high expense of sending out human labor. These problems can be effectively solved by combining 5G technology with drones, which makes it possible to access real-time data and analytics without requiring human intervention. This method greatly lowers the expenses and hazards related to manual inspections while also increasing the effectiveness and safety of maintenance operations [10].

The use of drones, supported by the robust connectivity provided by 5G networks, allows for the inspection and monitoring of power transmission infrastructure in areas that are otherwise difficult to access. This includes regions with rough terrain, extreme weather conditions, or those that are geographically isolated [11].

Advanced sensor-equipped drones can gather detailed data that can be transferred over 5G networks for real-time analysis. This capacity is essential for seeing possible problems before they become serious, enabling prompt maintenance, and averting expensive outages [10].

The integration of 5G technology and drone capabilities in proactive maintenance is transforming the power transmission industry. This combination leads to a multitude of benefits, including enhanced worker safety, potential lifesaving by preventing accidents, cost savings from averting major repairs, and optimized resource allocation.

The use of drones for maintenance tasks significantly reduces the need for workers to perform hazardous inspections at great heights or in dangerous conditions. Coupled with the real-time data transmission capabilities of 5G, drones can quickly relay information to safety personnel, leading to improved response times and potentially saving lives [12].

By enabling more frequent and thorough inspections, 5G and drones help in identifying potential hazards before they lead to accidents. This proactive approach to maintenance can prevent incidents that could disrupt service and pose risks to public safety [13].

Proactive maintenance using 5G and drones can lead to substantial cost savings. By detecting issues early, companies can avoid the high costs associated with emergency repairs and unplanned outages. Additionally, the data collected can be used to perform predictive analytics, further reducing maintenance costs over time [14].

With the detailed insights provided by drone-collected data, power transmission companies can better allocate their resources. This includes prioritizing maintenance tasks, deploying crews more efficiently, and managing inventory more effectively [13].

The implementation of 5G and drone technology in the power transmission industry has led to significant improvements in operational efficiency, safety, and cost management. Several case studies have documented the success stories of power transmission companies that have embraced these technologies.

One notable case study involves a power transmission company that reported a marked reduction in downtime after integrating 5G-enabled drones into their maintenance operations. The drones provided rapid diagnostics of the transmission lines, leading to quicker response times and less time spent on repairs. This not only improved the safety records by minimizing the exposure of maintenance crews to high-risk environments but also enhanced the overall reliability of the power supply [15].

Testimonials from various companies have underscored the positive impact of 5G and drone technology on operational continuity and safety. For instance, a testimonial from a power transmission operator described how the real-time data provided by drones enabled the company to pre-emptively address potential issues, thereby avoiding outages and ensuring a continuous power supply [16].

The deployment of 5G and drone technologies in the power transmission industry is not without its challenges. Technical and regulatory hurdles must be navigated to ensure successful implementation, particularly in the areas of data privacy and security during real-time monitoring.

One of the primary technical challenges is ensuring robust cybersecurity measures are in place to protect the data transmitted by drones over 5G networks. The high-speed connectivity and low latency of 5G are advantageous for real-time monitoring, but they also open up potential vulnerabilities to cyber-attacks, which could compromise sensitive infrastructure data [17].

Ensuring data privacy and security is paramount, as drones collect and transmit large volumes of potentially sensitive data. The integration of machine learning and artificial intelligence in 5G networks can enhance security protocols, but it also raises concerns about data protection and the potential for unauthorized access [18].

Regulatory challenges include compliance with aviation and spectrum-use regulations, which can vary significantly by region. The use of drones for maintenance in the power transmission industry must adhere to these regulations to avoid interference with other airspace users and communication services [17].

Power transmission businesses can take a multifaceted approach to overcoming these obstacles, which includes:

The power transmission industry is on the cusp of a technological revolution, with emerging trends in 5G, drone technology, and AI and machine learning poised to significantly enhance predictive maintenance capabilities. These innovations promise to improve system reliability, optimize maintenance schedules, and reduce operational costs.

The deployment of 5G networks is expected to improve the communication capabilities of drones, enabling them to transmit high volumes of data with minimal latency. This will allow for more sophisticated analysis and real-time decision-making, which is crucial for predictive maintenance [19].

AI and machine learning are set to play a pivotal role in predictive maintenance. These technologies can process and analyze vast amounts of data collected by drones and sensors, identifying patterns that indicate potential failures. Machine learning algorithms can predict when and where maintenance should be performed, leading to more efficient use of resources and reduced downtime [19].

The integration of AI in predictive analytics will enable the development of more accurate models for predicting equipment failure. This will not only enhance the reliability of power transmission systems but also extend their lifespan and reduce maintenance costs. AI-driven predictive maintenance can lead to a more proactive approach, where issues can be addressed before they escalate into major problems [19].

Incorporating video recognition technology into drones significantly enhances their capabilities in the power transmission industry. This subset of computer vision allows drones to perform complex tasks such as object detection, activity recognition, and scene understanding. These tasks are integral to identifying and interpreting content within video frames, which is essential for enhanced maintenance operations.

Finding and identifying things inside video frames is the task of object detection in video recognition. This technology allows drones to identify anomalies or modifications to the power transmission system, such as overheated or broken portions. Drones with activity recognition capabilities can comprehend and report on actions that take place in their area of vision, which is very helpful for keeping an eye on the status of projects and guarantee that safety procedures are being followed [20].

Scene comprehension is recognizing the context of the scene in entirety, in addition to identifying specific objects or actions. This implies that drones can evaluate the state of the infrastructure in its surroundings for power transmission maintenance, considering elements like the weather, the vegetation around it, and other possible risks [8].

Drone maintenance operations become more accurate and efficient when video recognition technology is integrated. Large areas may be swiftly surveyed by drones, giving operators access to real- time data that helps them make wise judgments. Additionally, this technology eliminates the need for labor-intensive and potentially hazardous manual inspections [8].

One major development in the proactive maintenance of power transmission lines is the employment of video recognition technology in drones. The power transmission industry's maintenance operations will become even more efficient, safe, and cost-effective as this technology develops.

The use of 5G technology together with drones in power transmission and distribution is a revolution in the way maintenance is done as outlined below: Transition from the reactive to Predictive Maintenance supported by technologies like IoT, AI, and now 5G and drones enables the more reliable and efficient supply of power. With high-tech cameras and sensors mounted on drones, and the help of 5G which supplies high-speed data at low latency, drones are used for real-time monitoring and predictive analysis. This makes it possible for power transmission companies to plan for any problems that are likely to arise regarding the equipment and conduct maintenance before mishaps occur- reducing instances of planned outages and increasing the durability of crucial facilities.

The benefits of these technologies include, for instance, lower downtime, better health of their employees and significant savings. The fact that 5G will allow for precise inspection in remote areas and complex terrains highlights the importance of combining the two technologies. Still, the advantages outweigh the disadvantages: cybersecurity, data privacy, and regulatory compliance constitute some of the hurdles. These challenges can be minimized by the power transmission companies through engaging proper encryption, better cybersecurity measures, and strong association with the authorities.

Looking ahead, the outlook for the application of predictive maintenance in the power transmission business is bright. Maintenance operations will continue to progress due to advancement in Artificial Intelligence and Machine learning as well as video recognition technology in the drones. Over time these technologies will become more crucial in the maintenance of integrity and reliability of power supply systems across the world. The utilization of 5G and drones is not only a technological solution but the necessity for the proper functioning of the power transmission system that contributes to the sustainable development goals.