Author(s): <p>Siyka Demirova* and Hristo Hristov</p>

In this report we look at the one of the most important and rapid evolving business aspects such as the E-Logistics and its interaction with the Information Flows, used in the industrial systems. The goal is to define the correct structure, the right place for the interaction, as well as the basics of building complete logistics system and its interaction with the information flows in the frame of the organization.

Information flows in the logistics. Concept, characteristics and options for interaction between the different information flows in the logistics.

Information flows in logistics refer to the movement of data and communication within the supply chain to ensure the efficient and effective management of goods and services. These information flows play a crucial role in coordinating various activities such as inventory management, transportation, warehousing, and order processing.

Characteristics of information flows in logistics include real-time tracking, visibility, accuracy, and timeliness. Real-time tracking allows for monitoring the status of shipments and inventory levels, while visibility provides stakeholders with insights into the entire supply chain process. Accuracy ensures that the information exchanged is reliable and error-free, while timeliness ensures that data is shared promptly to support decision-making.

By optimizing the interaction between different information flows in logistics, organizations can enhance operational efficiency, reduce costs, improve customer satisfaction, and gain a competitive advantage in the market [1].

The structure that builds the logistics information flow, represents the information system organized within the logistics information, acting in the direction of a certain and sought solution, as a mandatory condition for the data to have a common source or a common receiver. A typical structure of the logistics information flow is as shown in Figure 1.

Figure 1: Structure of the Logistic Information Flow

Modules are system blocks for processing information, such as accepting orders or allocating material resources according to those orders. The Data files appear as data for the infrastructure of the information system, in which information is stored, divided into functionally homogeneous groups. Management and data entry represent a type of interface through which the logistics system is fed from external sources, or those elements of the logistics chain that make decisions within the organization itself or are performed by suppliers external to the company. Reports contain information about logistics operations and interwoven functional relationships. Communication channels, which are also channels for information exchange, ensure the interaction of the elements of the information system both within the company and with the surrounding environment. The flow of logistics information passes through modules as shown in Figure 2.

Figure 2: Logistics Information Flow

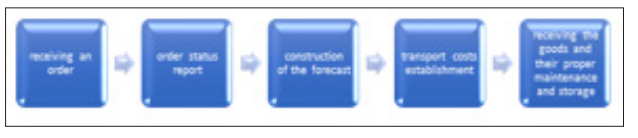

The files containing data and information ensure the interaction between the components within the logistics system. The core database that serves to inform distribution operations consists of the following files: order data, resource and inventory inventory data, receivables, and data required for distribution needs planning. The data management and input module are included in the data processing process, in cases where information is received from outside the LIS or when a strategic decision needs to be made. This usually happens in situations (Figure 3):

Figure 3: Stages in Processing Logistics Information

The report consists of multiple, summary, detailed and related references that represent the information support for logistics operations. The movement of the information flow connecting all these components is carried out through communication channels. Important for logistics is the methodological importance of determining the interaction between material and information flows [2]. The flow of materials generates an information flow, and the rules of movement of the material flow are precisely defined. Modern information technologies change the sequence of interaction between material and information flows, and thus several options for their interaction are being determined.

The interaction between different information flows in logistics is essential for ensuring the smooth and efficient operation of the supply chain. Information flows in logistics encompass various aspects such as inventory management, transportation planning, order processing, and warehousing. These different flows of information need to interact seamlessly to enable effective coordination and decision-making throughout the supply chain.

One key aspect of interaction between information flows in logistics is data sharing and integration. This involves ensuring that relevant information is shared in real time between different stakeholders, systems, and processes within the supply chain. By integrating systems and sharing data, organizations can improve visibility, accuracy, and timeliness of information, leading to better decision-making and operational efficiency [3].

Another important aspect of interaction between information flows in logistics is communication and collaboration. Effective communication among stakeholders, such as suppliers, manufacturers, distributors, and customers, is crucial for aligning on goals, sharing insights, and resolving issues in a timely manner. Collaborative planning and decision-making processes help in optimizing resources, reducing lead times, and enhancing overall supply chain performance.

Furthermore, the use of technology and digital tools plays a significant role in facilitating interaction between different information flows in logistics. Technologies such as supply chain management systems, transportation management systems, and data analytics platforms enable organizations to streamline processes, automate tasks, and gain actionable insights from data. These tools help in connecting different information flows, improving data accuracy, and enhancing communication across the supply chain [4].

Overall, effective interaction between the different information flows in logistics is vital for achieving operational excellence, reducing costs, enhancing customer satisfaction, and gaining a competitive edge in the market. By focusing on data sharing, communication, collaboration, and technology integration, organizations can optimize their supply chain processes and drive business success [5].

Electronic logistics, also known as e-logistics, refers to the use of electronic technologies and systems to streamline and optimize the processes involved in the transportation, storage, and distribution of goods. This includes the use of electronic data interchange (EDI), RFID technology, GPS tracking, and other digital tools to enhance efficiency, visibility, and coordination in the supply chain. By leveraging electronic logistics solutions, businesses can improve inventory management, reduce transportation costs, and enhance overall operational performance [6].

In logistics, information flow refers to the movement of data and information throughout the supply chain to facilitate the efficient and effective management of goods and services. AI, or artificial intelligence, plays an important role in improving the flow of information in logistics. AI technologies, such as machine learning and predictive analytics, can analyze vast amounts of data in real time, enabling logistics professionals to make more informed decisions. These technologies can optimize route planning, inventory management and demand forecasting, resulting in improved operational efficiency and cost savings. In addition, AI-powered systems can automate various tasks such as order processing, shipment tracking, and warehouse management. This automation reduces manual errors, speeds up processes and improves overall accuracy. AI also enables the integration of various data sources, such as IoT devices, sensors and GPS systems, to provide real time visibility and tracking of goods throughout the supply chain. This visibility helps identify bottlenecks, optimize delivery routes and ensure timely and accurate deliveries. Overall, AI improves the information flow in logistics by providing real-time data analysis, task automation, integration of data sources and improved visibility across the supply chain. This leads to increased efficiency, cost savings and better customer satisfaction.

The logistics highly-automated information system (E-LIS) is a new type of system, which is characterized as a system of interconnection of computer technologies and artificial intelligence (AI) with the actions of logistics processes within the organization. It is the logistics system in combination with the information system that provides available correct information for organizing and implementing the planning and execution of logistics operations, thus forming and defining the essence of E-LIS (highly automated logistics information systems). The logistics highly automated information system (E-LIS) is a basic and defining element of the company’s information system. It is considered as an element of the company’s information system due to the fact that it can only function if it is at the same E-level as the company itself. Therefore, the digitalization of logistics activities, as an element of the overall company development, is also considered as a complex solution through the digitalization of all company activities. Figure 4 shows the sequence of solving logistics tasks.

Figure 4: Methodological Consistency in Solving a Logistical Problem

The logistics highly automated information system (E-LIS) is a basic and defining element of the company’s information system. It is considered as an element of the company information system due to the fact that it can only function if it is on the same E-level as the organization or company. Therefore, the digitalization of logistics activities, as an element of the overall company development, is also considered as a complex solution through the digitalization of all company activities. The inability or unwillingness of the organization to install E-LIS as an integral part of company processes leads to the inability of the company to follow modern trends and processes, making it unstable to the processes in its surrounding environment. The internal-structural interrelationships are examined and arranged by significance and belonging according to certain signs to E-LIS. Here are also the interrelationships of the logistics of the material flow, such as the possibility of using a digital logistics information system related to the material flow in the company. This includes building a logistics virtual model in virtual reality with a mirror image - software implementation. External connections are related to the types of logistics systems, including the connections with external suppliers and customers.

The principle of logistics information processes as a hybrid element of the cyber production system refers to the integration of information technology and physical operations in the logistics area. It recognizes that logistics operations no longer rely solely on physical processes, but are also highly dependent on the effective management and use of information.

In this context, logistics information processes play a crucial role in optimizing the flow of materials, information, and resources throughout the production process. By leveraging digital technologies and data-driven insights, businesses can enhance efficiency, visibility, and coordination in their supply chain operations. This integration of logistics and information processes as a hybrid element within the cyber-production system enables organizations to adapt to changing market demands, improve decision-making, and drive overall operational performance [7-9].

In a cyber-manufacturing system, logistics information processes include the collection, analysis and dissemination of data throughout the supply chain. This includes activities such as order processing, inventory management, transportation planning and tracking of goods. By leveraging information technologies such as AI, IoT and cloud computing, logistics organizations can streamline their operations and improve overall efficiency. These technologies enable real-time data exchange, task automation and advanced analytics, enabling better decision-making and optimization of logistics processes.

The hybrid nature of logistics information processes means that physical operations and information management are interconnected and interdependent. For example, real-time tracking of shipments using GPS technology provides valuable data that can be used to optimize delivery routes and improve customer service. In addition, the integration of information processes in the cyber manufacturing system enables better coordination and cooperation between the various stakeholders in the supply chain. This includes suppliers, manufacturers, distributors and customers accessing and sharing relevant information to ensure smooth and efficient logistics operations.

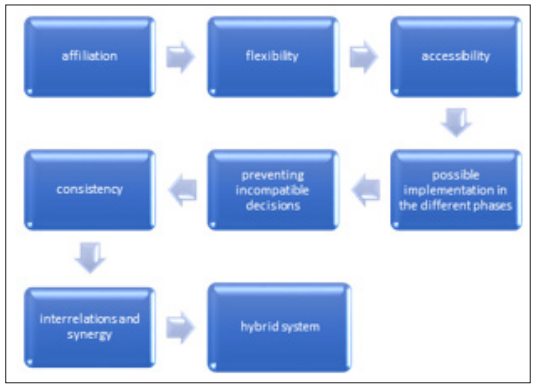

In summary, the principle of logistics information processes as a hybrid element of the cyber manufacturing system recognizes the critical role of information technology in modern logistics. It emphasizes the integration of physical operations with information management to achieve improved efficiency, coordination and optimization throughout the supply chain [10,11]. The components of the Internet of Things and the Internet of Services enable the gradual construction of an automated hybrid logistics system, as well as a drastic expansion of its scope. Logistics information systems (LIS), already built on the basis of computer technologies, like other automated management systems, are constantly improve. This leads to the mandatory condition that when designing them, it is necessary to provide an additional opportunity to constantly increase the number of objects for automation, as well as the opportunity to expand the composition of functions and the number of tasks that are performed by the information system [12]. Determining the stages of creating the system, namely the selection and setting of priorities when setting tasks, has a consequential impact on the subsequent development of the logistics information system, as well as on the effectiveness of its functioning. Figure 5 explains the function of this system, as well as the method of construction.

Figure 5: Step-by-step Construction of Hybrid LIS

The principle of logistic information processes as a hybrid element of the cyber-production system refers to the integration of logistics and information technology within the production system. This concept involves the use of digital tools and technologies to optimize the flow of materials, information, and resources throughout the production process. By leveraging data analytics, automation, and real-time communication, organizations can enhance efficiency, reduce costs, and improve overall performance. The seamless integration of logistics and information processes is essential for achieving a competitive edge in today’s digital economy.

The study showed that the interaction between logistics flows and electronic systems is key to the development of any company. Critical to the success of any new business venture is the security of systems and the interaction between logistics flows within the organization. The presence of these effective interactions is the main factor that defines a good logistics organization, because if the logistics service is not up to the level, the tasks set before the organization or the units cannot be fulfilled. Basing the entire supply chain of a company on the principles of interaction between information flows and electronic logistics enables the sustainable development of logistics processes and makes the organization itself develop in parallel with the direction of development of the needs of end users and the surrounding environment.

The interaction between information logistics flows in the industrial system and the external E-Logistics chain is crucial for ensuring seamless operations and efficient supply chain management. Information logistics flows within the industrial system involve the exchange of data, communication, and coordination of activities to support production processes and decision making. On the other hand, the external E-Logistics chain encompasses the flow of information, goods, and services between different entities in the supply chain, including suppliers, manufacturers, distributors, and customers.

Effective interaction between these two components is essential for optimizing inventory management, reducing lead times, improving visibility, and enhancing overall supply chain performance. By integrating information logistics flows within the industrial system with the external E-Logistics chain, organizations can achieve greater transparency, collaboration, and responsiveness in their operations. This integration enables real time data sharing, streamlined communication, and better coordination of activities across the entire supply chain network, ultimately leading to increased efficiency and customer satisfaction.