Enhancing Supply Chain Efficiency and Performance Through ERP Optimisation Strategies

Author(s): <p>Purna Chandra Rao Chinta*, Krishna Madhav Jha, KishanKumar Routhu, Vasu Velaga, Chethan Sriharsha Moore and Suneel Babu Boppana</p>

Abstract

As the supply chain environment has become very complex, there is a need for integration of ERP systems into Supply Chain Management. ERP enables enhanced management of material, information and financial flows in supply chains to meet important societal demands like demand volatilities, globalisation and sustainability, as analysed in this paper. The areas selected, production planning, inventory, and financial control, are evaluated to determine how ERP can improve operations and communication. Middleware and specific IT solutions for integration are mentioned, as well as problems in technical & organisational integration and data handling. The study also outlines measures of enhancing visibility, demand and real time decision making. A comprehensive review of the literature outlines the current trends, challenges and development in the integration of ERP-SCM. The results provide a solid basis for further research and improvements by highlighting the revolutionary potential of ERP systems to improve operational excellence and supply chain agility.

Introduction

There are many types of customers and players in the chain of supply, such as the suppliers of raw materials, producers, the middlemen, and the end users. Ideally, the whole system of material, information, and financial flows should occur in the organisation in an optimal manner. Products also circulate through the material flow in and out, from the suppliers to the consumers and back to the supplier for things such as repair, servicing, and returns. The information flow guarantees order and critical data and progress updates, closely related to goods flow. The last category is the financial flow which comprises payments, credits and financial transactions that are characteristics for maintaining operations.

In this interconnected landscape, Large software applications called ERP systems are utilised by organisations to manage their corporate operations. Software providers usually create ERP systems as bundled apps [1]. ERP encompass a wide range of functions, including but not limited to planning, auditing, finance, engineering, human resources, manufacturing, inventory management, and order processing. By enabling data entry once and accessibility by all users, this centralised and shared database system connects the whole organisation. There is also another smart way of completing business activities with fast and correct action. An all-inclusive and easily available master record may be created when manufacturers employ ERP in conjunction with supply chain execution [2].

An ERP-based supply chain system functions as an integrated approach to delivery scheduling, overall planning, and metrics- driven performance evaluation [3]. These systems are used to consistently define, predict, and improve supply chain functions as activities. Despite the importance of ERP systems in the practice of SCM, they belong to the family of methodologies designed to enhance efficiency [4]. Other approaches can also be used alongside ERP in resolving issues of operational scheduling and inventory problems [5].

Motivation of the Study

Correct management is gaining prominence because of the growing number of links within the supply chain, as well as the need to come up with decisions promptly. Consequently, ERP Systems, which enable the linking and control of most business activities, can be used to solve existing failures and enhance performance. The purpose of this paper is to identify the key ways for the optimization of ERP systems to improve supply chain velocity, responsiveness and flexibility in order to sustain business operations in a volatile and complex environment.

Structure of the Paper

The paper is structured as follows: Section II covers supply chain management (SCM), including components, challenges, and metrics. Section III explores ERP systems and their optimization modules. Section IV examines ERP-SCM integration, methods, and challenges. Section V reviews key literature, and Section VI concludes with findings and future directions.

Overview Of Supply Chain Management (SCM)

The term "Supply Chain Management" (SCM) refers to the practice of systematically coordinating and managing the activities of a network that links producers, wholesalers, retailers, and consumers to guarantee the smooth movement of products, data, and money. It covers the whole process, from obtaining raw materials to delivering completed goods to customers. Consequently, effective SCM emphasizes work improvement, cost control, and customer satisfaction to meet the solutions to problems like fluctuating demands, globalization, and sustainability issues. As a result of using better technologies and performance indexes, SCM helps decision-makers reduce threats and risks and gain competitive advantages in changing markets [6].

Key Components of a Supply Chain

Several interrelated parts make up a healthy supply chain:

- Suppliers: Assemble the necessary components or raw ingredients for manufacturing [7].

- Manufacturers: Execute a series of manufacturing steps to transform these inputs into final goods [8].

- Warehouses: Store goods until they are needed for distribution, ensuring a buffer between production and demand.

- Logistics Providers: Manage the transportation and delivery of products to various stakeholders, ensuring timely and efficient movement.

- Retailers: Sell the final products directly to consumers, acting as the final link in the supply chain [9].

- Customers: The end-users who purchase and consume the

Challenges in Managing Supply Chains

Managing supply chains involves navigating a complex array of challenges:

- Demand Variability: Fluctuations in customer demand can lead to inefficiencies such as overstocking or stockouts, impacting service levels and costs [10].

- Globalization: Operating across multiple countries introduces complexities related to diverse regulations, cultural differences, and extended logistics networks [11].

- Technological Advancements: Rapid technological changes necessitate continuous adaptation to maintain competitiveness and operational efficiency.

- Sustainability Concerns: There is a growing need to adopt environmentally responsible practices, which can complicate sourcing and production processes [12].

- Risk Management: Robust contingency planning is necessary because supply networks are susceptible to interruptions caused by natural catastrophes, geopolitical crises, and other unpredictable occurrences [13].

Metrics for Measuring Supply Chain Efficiency

To evaluate and enhance supply chain performance, organisations employ various key performance indicators (KPIs):

- Inventory Turnover Ratio: Measures the efficiency of inventory management by showing the frequency of sales and replacements over a certain time frame.

- Order Cycle Time: A good indicator of how quickly the supply chain responds to consumer demands is the average time it takes to complete an order [14].

- Fill Rate: Represents the percentage of customer demand met without backorders, assessing the ability to satisfy demand promptly [15].

- Supply Chain Cycle Time: Calculates the total time required to produce and deliver a product to the customer, encompassing all stages from order to delivery [16].

- Cash-to-Cash Cycle Time: The time it takes to get from paying for ingredients to getting paid for finished goods is an indicator of liquidity [17].

- On-Time Delivery Rate: Indicates dependability by keeping tabs on the proportion of orders delivered by the specified date.

- Freight Cost per Unit Shipped: Assesses the cost efficiency of transportation by measuring shipping costs relative to the number of units delivered.

Enterprise Resource Planning (ERP) Systems

ERP system is a way for a manufacturing, distribution, or service organisation to efficiently plan and handle the resources required to receive, process, distribute, and account for client orders. A vendor- provided software package solution can facilitate this kind of integration by facilitating the smooth integration of all data moving through the business, including accounting, customer, financial, and human resources records [18]. The development of better computer systems and ERP system installation in manufacturing company operations relies heavily on IT infrastructure. It is considered that businesses using ERP systems may have several control and operating centres. Hence EDI, the Internet, intranets, and data warehousing are some of the enabling technologies that allow for cross-locational online data transmission [19]. This emphasises that ERP software consists of several software modules chosen according to the manufacturing units' economic and technological feasibility.

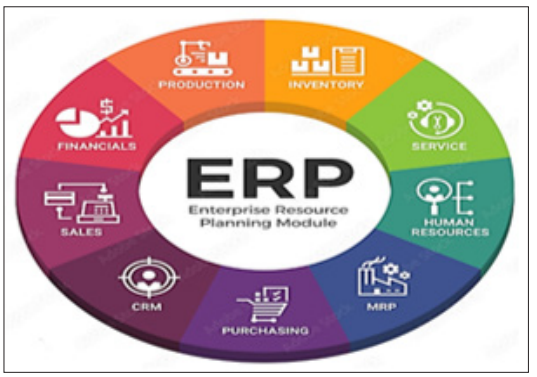

Figure 1: Enterprise Resource Planning Modules

ERP Modules for Supply Chain Optimization

Here are the typical basic modules that are included:

- ERP Production Planning Module: the goal here is to maximise the use of production capacity, components, parts, and materials by analysing past production data and projecting future sales [20].

- ERP Purchasing Module: It simplifies the acquisition of necessary raw materials by automating the steps of finding possible vendors, negotiating pricing, placing orders with vendors, and handling associated billing.

- ERP Inventory Control Module: makes it easier to keep the warehouse stocked with the right items by tracking inventory needs, creating goals, offering replenishment methods and choices, keeping tabs on item consumption, settling inventory balances, and reporting inventory status [21].

- ERP Sales Module: Order scheduling, placement, shipment, and billing are its primary Sales are the lifeblood of every organisation thus this is crucial.

- ERP Marketing Module: It's useful for generating leads, running a direct mailing campaign, and keeping up with consumer preferences.

- ERP Financial Module: ERP software systems rely on this module to compile financial data from several departments and provide reports like the balance sheet, general ledger, trial balance, and quarterly financial statements [22].

- ERP Human Resources (HR) Module: Every employee's contact information, compensation details, attendance, performance review, and promotion history is meticulously recorded in the comprehensive personnel database. Maximising the value of every employee's skillset depends on it [23].

- ERP in CRM: centralise customer data to improve sales marketing and service interaction. Tracks customer communication, lead management, and sales forecasts.

- Material Requirement Planning MRP: Ensures that materials and components are available for production. Coordinates production schedules, supplier deliveries, and raw material planning [24].

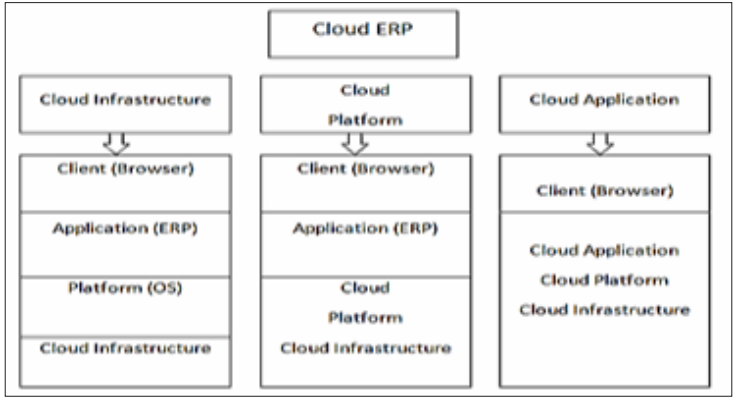

Types of Enterprise Resource Planning

An ERP system can be hosted on-premises or in the cloud. The ERP system's host servers are not located on-premises at the end user's business when the system is hosted in the cloud. If the software's license is purchased by the end user. Platform as a Service (PaaS), Infrastructure as a Service (IaaS), and Software as a Service (SaaS) are the three categories.

Figure 2: Types of ERP

- Platform as a Service (PAAS): The term PaaS refers to the capacity to utilise cloud infrastructure built with developer languages, libraries, services, and devices supported by providers in user-generated or purchased applications.

- Infrastructure as a service (IaaS): Providers of infrastructure IaaS allows users to access and use fundamental computer resources such as processing power, data storage, networks, and applications.

- Software as a Service (SaaS): Cloud computing enables software programs to be made available to customers through Thin client interfaces, like web clusters or program interfaces, make the applications accessible from a variety of client devices. Overspending and overruns are commonplace in ERP projects. To steer clear of these issues during ERP adoption efforts.

Three Key Areas Covered by the ERP Systems

- Customer Relationship Management (CRM) - It enables the administration to centralise all client data, so ensuring its accessibility to all corporate divisions as required. Until after a deal has been made, CRM tracks all aspects of the marketing and sales process involving the customer.

- Supply Chain Management System (SCM) - the administration of manufacturing material delivery procedures, including transportation, storage, and inventory control, through the use of a SCM system.

- Human Resource Management System (HRMS) - performs duties inside the organisation while including all facets of human resource management.

ERP Integration in Supply Chain Management

ERP competency is the fundamental prerequisite for integrating SCM with ERP, and it may act as the foundation for SCM. The ERP and SCM have a great deal of potential to enhance business performance. The ERP system meets the needs of SCM by integrating all facets of corporate organisation and offers several advantages. ERP focuses on optimising the physical distribution and information flow inside a single organisation. The whole supply chain is affected by the movement of money, information, and physical goods. Manufacturing management, HRM, financial management, operations management, SCM, and other key organisational tasks are all covered by ERP. Inventory management, logistics, production, and supply chain planning are all facets of the supply chain that SCM encompasses [25]. ERP system integrators have begun to integrate supply chain management apps into ERP systems, seeing the importance of ERP's modular improvements for SCM.

Methods of Supply Chain in ERP

Three different approaches exist for integrating ERP and SCM:

- All SCM Processes can be Modified to Embrace ERP Functions: Smaller supply chain settings can make this strategy work, but larger supply chains will find it impossible to implement. In addition to this, it becomes more difficult to handle the rights and securities associated with schemas and module owners.

- SCM as a Middleware for ERP: this necessitates the development of programmatic interfaces between different subsystems in order to incorporate the SCM capabilities into the second level of ERP The one and only negative of this strategy is that the advantages of ERP-SCM integration are sometimes undervalued compared to the costs of creating these links.

- Use SIS (Specialised Integration Software): thirdly, SIS software can be used for integration. Two subsystems' functioning and integration can be mapped Consequently, an ERP may transform into a data distribution facility, information repository, and business service framework with the help of SIS [26].

Challenges of ERP Optimizaation for Supply Chain

There are several distinct obstacles in the areas of technology, organisation, and data that arise when attempting to integrate AI with ERP systems:

Technical Challenges: Problems arise when trying to integrate AI tools with preexisting ERP systems when huge amounts of computing resources are required, and when trying to guarantee that AI models are compatible with the design of the ERP program.

Organizational Challenges: The process of integration could be very much affected by resistance to change within the organisations. It is possible for the employees to be afraid of using artificial intelligence technology or to fear that they might soon be replaced by robots. Furthermore, there might not be enough qualified workers to properly oversee and operate AI systems.

Data-Related Challenges: Large amounts of high-quality data are necessary for AI systems to operate at their best. Maintaining data cleanliness, uniformity, and correctness may be quite difficult. Furthermore, incorporating AI requires managing concerns about data security, privacy, and regulatory compliance.

Multi-Scale Challenges: Finding a supply chain's ideal structure and functioning requires coordination across its many geographical and temporal dimensions. It is difficult to model this cooperation. Supply chain and provide further difficulties for modelling. Lastly, a technological difficulty that has to be addressed is the solution of large-scale, complicated, multi-scale supply chain models. The emergence of the Big Data movement highlights this requirement even more.

Multi-Objective and Sustainability Challenges: The design criteria or objectives in the articulated design optimisation model are another key component in supply chain design. Multi-scale difficulties mostly concern the construction of supply chain design models or the limits of the generated models.

Algorithmic and Computational Challenge: Algorithmic and computational hurdles result from large-scale, complicated issues caused by optimising the design and operations of extensive, intricate supply chains. Research demands can only be satisfied with the creation of efficient computing techniques, such as new decomposition methods, optimisation algorithms, and computational tools [27].

Strategies for ERP Optimization in Supply Chains

- Inefficient Demand Forecasting: Improve demand forecasting accuracy, Reduce inventory holding costs, minimise stockouts, and improve customer satisfaction through better supply-demand alignment.

- Quality Control Issues: Decrease product defects by 15%. Lower production waste minimised recalls, and enhanced brand reputation due to improved product quality.

- Production Optimisation: Increase production efficiency, Reduce manufacturing costs, faster time-to-market, and enhanced capacity.

- Lack of Real-time Visibility Discover the complete supply chain in real-time. Improved decision-making based on real- time data, shorter response times to interruptions, and shorter processes overall.

- Lack of Real-time Visibility: Discover the complete supply chain in real-time. Improved decision-making based on real- time data, shorter response times to interruptions, and shorter processes overall.

Inadequate Product Traceability

Implement end-to-end product traceability for recalls within 4 hours. Minimized liability, enhanced customer safety, and faster recall resolution.

Data Silos

Do away with data silos and combine information from different sources. Enhanced cross-departmental cooperation, more accurate data, and better data-driven decisions [28].

Literature Review

This section presents a comprehensive literature review on enhancing supply chain efficiency and performance through ERP optimization strategies. Additionally, Table I summarizes the key aspects of the reviewed literature discussed in this section.

In this study, Gosavi and Thakare choosing an ERP is a difficult decision, and there isn't a set guideline. The most important but sadly overlooked technical optimisation plan articulation becomes a counting coin element once an ERP is chosen based on the volume of deployment and the vast physical and human resource set supporting it in the industry. To offer a full logic provision that is encapsulated in an algorithm that will support and aid in post- selection optimisation and intelligent, customised selection [29].

In this study, Asadujjaman, Alam and Moni suggest a change to the ERPS protocol that would allow adaptive modulation in an ERPS-protected microwave access network, which would increase efficiency, dependability, and throughput. To ensure that our suggested adjustment is successful, we offer a mathematical model. The suggested upgrade was achieved, according to the simulation findings [30].

In this study, Sharma and Gupta ERP is the industry that manufactures aeroplanes. The size of operations and the degree of mobility required for the development of an aeroplane are the most striking aspects of this business. Aircraft production planning necessitates managing intricate and interconnected processes based on a global supply chain network. Big aircraft manufacturing companies see ERP as a strategic management tool that gives them a competitive edge, helps them decrease operational costs, and simplifies procedures [31].

In this study, Suroso, Budhijana and Delfiani in order to investigate the impact of ERP systems on business outcomes, with an emphasis on the relationship between system and information quality, employee performance, user happiness, and system users as intermediaries. The findings demonstrate that system quality affects employee performance in two ways: directly and indirectly. The impact of information quality on employees' performance has also been found to be minimal. Both the number of users of the system and their level of satisfaction with it serve as intermediaries between the quality of the information and the performance of the employees [32].

In this study, Lopez, Luna and Talavera first implemented AHP as the best ERP system. To find out if the chosen ERP meets the operational and financial performance requirements of the company, an FIS is used. The last FIS, the so-called "acceptability level," combines all of these findings into a single overall score. The suggested approach is an attempt to put a number on all the subjective factors that go into an ERP purchase [33].

Table 1: The Literature Underscores ERP Systems' Role in Optimizing Supply Chain Efficiency and Performance

|

Reference

|

Challenge

|

Methodology

|

Key Findings

|

Limitation

|

Future Work

|

|

[29]

|

Selection of ERP and lack of technical optimization strategies post-selection.

|

Algorithm to assist in intelligent selection and optimization post-ERP selection.

|

ERP optimisation strategy becomes crucial post- selection for efficient implementation.

|

No universal approach; optimisation is heavily context- dependent.

|

Develop context- specific optimization strategies and frameworks.

|

|

[30]

|

Enhancement of ERPS protocol for adaptive modulation in microwave access networks.

|

Mathematical model and

simulations to verify proposed protocol enhancement.

|

Proposed protocol enhancement improves throughput, reliability, and energy efficiency.

|

Focus limited to microwave networks; applicability to other domains untested.

|

Extend protocol enhancements to diverse network types and scenarios.

|

|

[31]

|

Complexity and scale of operations in the aircraft manufacturing industry.

|

ERP as a strategic management tool in global supply chain operations.

|

ERP helps reduce operational costs and complexity in aircraft manufacturing.

|

Scalability challenges for smaller operations not addressed.

|

Address ERP scalability for varying organizational sizes and complexities.

|

|

[32]

|

Causal effect of ERP information systems on employee performance.

|

Examined quality of system and information with user satisfaction and system users as variables.

|

System quality significantly influences employee performance; information quality has negligible direct impact.

|

Information quality's indirect effects underexplored.

|

Explore additional intervening variables affecting ERP system outcomes.

|

|

[33]

|

Quantifying subjectivity in ERP acquisition decisions.

|

AHP for ERP selection followed by FIS for evaluation and acceptability assessment.

|

Methodology quantifies subjectivity in ERP acquisition with an 'acceptability level' metric.

|

Subjectivity quantification depends on predefined criteria; limited generalizability.

|

Refine methodology for broader applicability across industries.

|

Conclusion and Future Work

The integration of ERP systems into SCM represents a transformative approach to enhancing efficiency, collaboration, and decision-making across organisations. By streamlining material, information, and financial flows, ERP systems enable businesses to address challenges such as demand variability, data silos, and production inefficiencies. Despite the complexities associated with ERP optimisation—ranging from technical to organisational and computational challenges—strategic implementation of ERP solutions can significantly improve operational outcomes, customer satisfaction, and overall supply chain resilience. This study highlights the critical role of ERP in addressing inefficiencies and providing a unified framework for end-to-end supply chain management.

To further improve ERP skills in SCM, future studies should concentrate on using new technologies like AI, ML, and blockchain. This includes developing advanced predictive analytics for demand forecasting, improving real-time data visibility, and addressing multi-scale challenges in large-scale supply chains. Additionally, integrating sustainable practices into ERP systems to achieve environmentally responsible supply chains warrants further exploration. Expanding studies on cloud-based ERP solutions and their scalability for global supply chain operations can also provide valuable insights into cost-effective and flexible SCM strategies [34-50].

References

- Kumar VV, Pandey MK, Tiwari MK, Ben-Arieh D (2010) Simultaneous optimization of parts and operations sequences in SSMS: A chaos embedded Taguchi particle swarm optimization approach. J Intell Manuf 21: 335-353.

- Handoko BL, Aryanto R, So IG (2015) The Impact of Enterprise Resources System and Supply Chain Practices on Competitive Advantage and Firm Performance: Case of Indonesian Companies. Procedia Computer Science 72: 122- 128.

- Kumar V, Chan FTS (2011) A superiority search and optimisation algorithm to solve RFID and an environmental factor embedded closed loop logistics Int J Prod Res 49.

- Kumar VV, Liou FW, Balakrishnan SN, Kumar V (2015) Economical impact of RFID implementation in remanufacturing: a Chaos-based Interactive Artificial Bee Colony approach. J Intell Manuf 26: 815-830.

- Ho CJ (2007) Measuring system performance of an ERP- based supply chain. Int J Prod Res 45: 1255-1277.

- Kumar VV, Tripathi M, Pandey MK, Tiwari MK (2009) Physical programming and conjoint analysis-based redundancy allocation in multistate systems: A Taguchi embedded algorithm selection and control (TAS&C) approach. Proc Inst Mech Eng Part O J Risk Reliab 223: 215-232.

- Melo MT, Nickel S, Saldanha-da-Gama F (2009) Facility location and supply chain management - A review. Eur J Oper Res 196: 401-412.

- Kumar VV, Yadav SR, Liou FW, Balakrishnan SN (2013) A digital interface for the part designers and the fixture designers for a reconfigurable assembly system. Math Probl Eng https://wiley.com/doi/10.1155/2013/943702.

- Kumar VV, Chan FTS, Mishra N, Kumar V (2010) Environmental integrated closed loop logistics model: An artificial bee colony approach. Proceedings of 2010 8th International Conference on Supply Chain Management and Information Systems: Logistics Systems and Engineering https://ieeexplore.ieee.org/document/5681670.

- Kumar VV, Sahoo A, Liou FW (2019) Cyber-enabled product lifecycle management: A multi-agent framework. Procedia Manufacturing 39: 123-131.

- Wu L, Yue X, Jin A, Yen DC (2016) Smart supply chain management: A review and implications for future Int J Logist Manag 10.1108/IJLM-02-2014-0035.

- Kumar VV, Tripathi M, Tyagi SK, Shukla SK, Tiwari MK (2007) An integrated real time optimization approach (IRTO) for physical programming based redundancy allocation problem. 3rd Int Conf Reliab Saf Eng 692-704.

- Farooq Q, Fu P, Hao Y, Jonathan T, Zhang Y (2019) A Review of Management and Importance of E-Commerce Implementation in Service Delivery of Private Express Enterprises of SAGE Open https://journals.sagepub.com/doi/10.1177/2158244018824194.

- Kumar V, Kumar VV, Mishra N, Chan FTS, Gnanasekar B (2010) Warranty failure analysis in service supply Chain a multi-agent framework. Proceedings of 2010 8th International Conference on Supply Chain Management and Information Systems: Logistics Systems and Engineering https://pureportal.bcu.ac.uk/en/publications/warranty-failure-analysis-in-service-supply-chain-a-multi-agent-f.

- Kumar VV (2014) An interactive product development model in remanufacturing environment : a chaos-based artificial bee colony approach. Missouri University of Science and Technology https://scholarsmine.mst.edu/cgi/viewcontent.cgi?article=8243&context=masters_theses.

- Behl A, Dutta P (2019) Humanitarian supply chain management: a thematic literature review and future directions of research. Ann Oper Res 10.1007/s10479-018-2806-2.

- Kishore Mullangi MR, Vamsi Krishna Yarlagadda, Niravkumar Dhameliya (2018) Integrating AI and Reciprocal Symmetry in Financial Management: A Pathway to Enhanced Decision-Making. Int J Reciprocal Symmetry Theor. Phys 5: 42-52.

- Sai Charan Reddy Vennapusa SKRA, Takudzwa Fadziso, Dipakkumar Kanubhai Sachani, Vamsi Krishna Yarlagadda (2018) Cryptocurrency-Based Loyalty Programs for Enhanced Customer Engagement. Technol Manag Rev 3: 46-62.

- Shajahan MA, Richardson N, Dhameliya N, Patel B, Anumandla SKR, et al. (2019) AUTOSAR Classic vs. AUTOSAR Adaptive: A Comparative Analysis in Stack Development. Eng Int 7: 161-178.

- Nicholas Richardson VKY, Rajani Pydipalli, Sai Sirisha Maddula, Sunil Kumar Reddy Anumandla (2019) Role-Based Access Control in SAS Programming: Enhancing Security and Int J Reciprocal Symmetry Theor Phys 6: 31-42.

- Hasan MZ, Fink R, Suyambu MR, Baskaran MK (2012) Assessment and improvement of intelligent controllers for elevator energy efficiency. IEEE International Conference on Electro Information Technology https://ieeexplore.ieee.org/document/6220727.

- Madanhire I, Mbohwa C (2016) Enterprise Resource Planning (ERP) in Improving Operational Efficiency: Case Study. Procedia CIRP 40: 225-229.

- Hasan MZ, Fink R, Suyambu MR, Baskaran MK, James D, et al. (2015) Performance evaluation of energy efficient intelligent elevator IEEE International Conference on Electro Information Technology https://ieeexplore.ieee.org/document/7293320.

- Sanjay Sharma RKA, Munish Gupta, Ajay Kumar (2012) Risk assessment exposure to radon concentration and heavy metal contamination in drinking water samples in some areas of Jammu and Kashmir, Journal of Radioanalytical and Nuclear Chemistry 304.

- Koh SCL, Ganesh K, Pratik V, Anbuudayasankar SP (2014) Impact of ERP implementation on supply chain performance. Int J Product Qual Manag 14: 196-227.

- Garcia DJ, You F (2015) Supply chain design and optimization: Challenges and Comput Chem. Eng 81: 153- 170.

- Coppedge M (2004) Supply chain management 49th Annu Air Traffic Control Assoc Conf Proc Fall 2004 81-85.

- Gosavi GR, Thakare VM (2018) Mathematically Modeled Algorithm for Intelligently Customized Optimization of an Erp. Fourth International Conference on Computing Communication Control and Automation (ICCUBEA), IEEE 1-11.

- Asadujjaman ASM, Alam MS, Moni SS (2017) Optimization of ethernet ring protection switching for adaptive modulation in carrier access network. 19th International Conference on Computer and Information Technology, ICCIT https://ieee.org/document/7860161.

- Sharma A, Gupta S (2014) Identifying the role of ERP in enhancing operational efficiency and supply chain mobility in aircraft manufacturing industry. Proceedings of the 2014 International Conference on Issues and Challenges in Intelligent Computing Techniques, ICICT https://ieeexplore.ieee.org/document/6781302 .

- Suroso JS, Budhijana RB, Delfiani RI (2018) The Effect of Successful Enterprise Resource Planning (ERP) Systems on Employee Performance. International Conference on Orange Technologies, ICOT https://www.researchgate.net/publication/333230150_The_Effect_Of_Successful_Enterprise_Resource_Planning_ERP_Systems_On_

- Lopez Y, Luna D, Talavera A (2017) Selection of ERP based on analytical hierarchical process and fuzzy inference Proceedings of the 2017 IEEE 24th International Congress on Electronics, Electrical Engineering and Computing, INTERCON https://faculty.up.edu.pe/en/publications/selection-of-erp-based-on-analytical-hierarchical-process-and-fuz-2.

- Gagan Kumar Patra, Shravan Kumar Rajaram, Venkata Nagesh Boddapati (2019) AI And Big Data in Digital Payments: A Comprehensive Model For Secure Biometric Authentication. Educational Administration: Theory and Practice 25: 773-781.

- Chandrababu Kurakula, Hemanth Kumar Gollangi, Janardhana Rao Sunkara (2020) Biometric Authentication In Digital Payments: Utilizing AI And Big Data For Real- Time Security And Educational Administration: Theory and Practice 26: 954-964.

- Eswar Prasad Galla, Chandrakanth Rao Madhavaram, Venkata Nagesh Boddapati (2021) Big Data And AI Innovations In Biometric Authentication For Secure Digital Transactions Educational Administration: Theory and Practice 27: 1228-

- Janardhana Rao Sunkara, Sanjay Ramdas Bauskar, Chandrakanth Rao Madhavaram, Eswar Prasad Galla, Hemanth Kumar Gollangi (2021) Data-Driven Management: The Impact of Visualization Tools on Business Performance, International Journal of Management (IJM) 12: 1290-1298.

- Mohit Surender Reddy, Manikanth Sarisa, Siddharth Konkimalla, Sanjay Ramdas Bauskar,

- Hemanth Kumar Gollangi, et (2021) Predicting tomorrow’s Ailments: How AI/ML Is Transforming Disease Forecasting. ESP Journal of Engineering & Technology Advancements 1: 188-200.

- Gollangi K, Bauskar SR, Madhavaram CR, Galla P, Sunkara JR (2020) Echoes in pixels : the Intersection of image processing and sound open access echoes in pixels : the Intersection of image processing and sound detection. Int J Dev Res 10: 39735-39743.

- Gollangi HK, Bauskar SR, Madhavaram CR, Galla EP, Sunkara JR, et al. (2020) Unveiling the Hidden Patterns: AI-Driven Innovations in Image Processing and Acoustic Signal Detection. Journal of Recent Trends in Computer Science and Engineering 8: 25-45.

- Gollangi HK, Bauskar SR, Madhavaram CR, Galla EP, Sunkara JR, et al. (2020) Exploring AI Algorithms for Cancer Classification and Prediction Using Electronic Health Journal of Artificial Intelligence and Big Data 1: 65-74.

- Chandrakanth RM, Eswar PG, Mohit SR, Manikanth S, Venkata NB, et al. (2021) Predicting Diabetes Mellitus in Healthcare: A Comparative Analysis of Machine Learning Algorithms on Big Dataset. Global Journal of Research in Engineering and Computer Sciences 1: 1-11.

- Krutthika HK (2019) Modelling of data delivery modes of next-generation SOC-NOC router. 2019 IEEE Global Conference for Advancement in Technology https://ieee.org/document/8978290.

- Pavitha US, Nikhila S, Krutthika HK (2012) Design and implementation of image dithering engine on a spartan 3AN FPGA. Intern J Future Compt Comm 1: 361-365.

- Nikhila S, Pavitha US, Krutthika HK (2014) Face recognition using wavelet transforms. International Journal of Advanced Research in Electrical Electronics and Instrumentation Engineering 3: 6740-6746. Krutthika HK, Rajashekhara (2019) Modeling of Data Delivery Modes of Next Generation SOC-NOC Global Conference for Advancement in Technology (GCAT) 1-6.

- Kalla D, Kuraku DS, Samaah F (2021) Enhancing cyber security by predicting malwares using supervised machine learning models. International Journal of Computing and Artificial Intelligence 2: 55-62.

- Kalla D, Smith N, Samaah F, Polimetla K (2021) Facial Emotion and Sentiment Detection Using Convolutional Neural Network. Indian Journal of Artificial Intelligence Research (INDJAIR) 1: 1-13.

- Kuraku S, Kalla D (2020) Emotet malware—a banking credentials IOSR Journal of Computer Engineering (IOSR-JCE) 22: 31-41.

- Kalla D, Samiuddin V (2020) Chatbot for medical treatment using NLTK IOSR Journal of Computer Engg 22: 50-56.

View PDF