Author(s): Sahil Nyati

This research paper proposes an enhanced Digital Vehicle Inspection Report (DVIR) system that leverages artificial intelligence (AI) to revolutionize defect tracking and management in fleet operations. The system aims to support associating and tracling defects on a per-asset basis and individually handling these defects with advanced AI capabilities.

The proposed solution to enhance the Digital Vehicle Inspection Report (DVIR) product revolves around integrating advanced artificial intelligence (AI) capabilities. This expansion focuses on a detailed breakdown of how AI can be incorporated into various aspects of the DVIR system to improve efficiency, accuracy, and compliance.

• Develop AI-driven dashboards for managers, showcasing realtime fleet status, defect resolution progress, and compliance

reports.

• Implement anomaly detection systems to alert managers about

critical issues in the fleet.

• Ensure AI models are trained in line with industry regulations

and safety standards.

• Automatic documentation and reporting features to maintain

regulatory compliance, especially for critical defects that

could render an asset non-compliant.

By infusing AI into the DVIR system, the solution not only enhances the efficiency of asset management and defect handling but also brings a new level of intelligence and foresight into fleet operations. It represents a significant step towards a more datadriven, predictive approach to vehicle inspection and maintenance in the logistics and transportation industry.

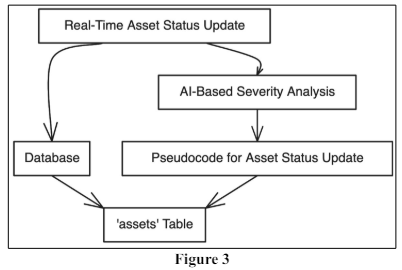

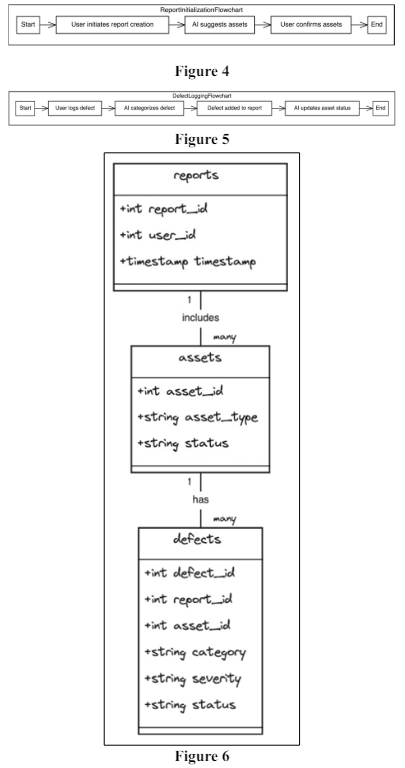

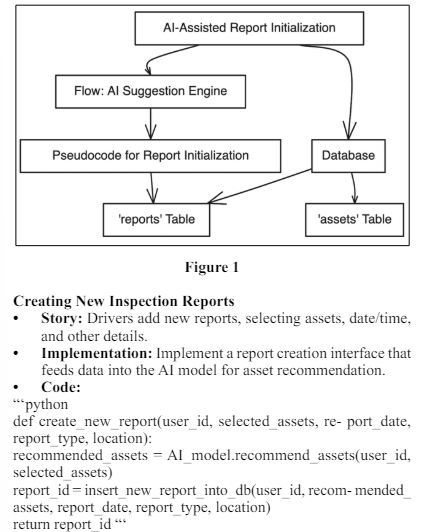

Incorporating AI into the DVIR system revolutionizes the user experience by streamlining workflows, enhancing decisionmaking, and automating defect management. Below is an expanded overview of the enhanced user flow, supported by AI, with corresponding database design, pseudocode, and flowcharts.

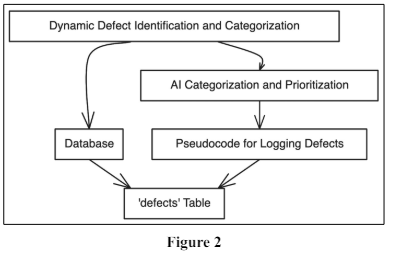

• ‘reports‘ to ‘assets‘: One-to-many, as each report can include

multiple assets.

• ‘assets‘ to ‘defects‘: One-to-many, as each asset can have

multiple defects.

Enhancing the DVIR system with AI support greatly improves the user experience for both drivers and managers. Below, we explore key user stories that are enhanced by AI, along with detailed code examples illustrating how these functionalities can be implemented.

• Story: Drivers can access the DVIR system only if they have

the appropriate permissions.

• Implementation: Use an authentication and authorization

system to control access.

• Code:

“‘python

def access_dvir(user_id):

if has_permission(user_id, "DVIR_ACCESS"): dvir_reports =

get_dvir_reports(user_id)

return dvir_reports else:

raise AccessDeniedException("User lacks DVIR access

permission.")

“‘

• Story: Drivers select vehicles and view past reports for those

vehicles.

• Implementation: Fetch vehicle data and related reports from

the database.

• Code:

“‘sql

SELECT * FROM reports WHERE vehicle_id = ? AND report_

date >= ?

“‘

“‘python

def get_past_reports(vehicle_id, days=8): past_date = get_date_

days_ago(days)

reports = execute_sql_query("SELECT * FROM reports WHERE

vehicle_id = ? AND report_date >= ?", [vehicle_id, past_date])

return reports “‘

• Story: Managers audit and certify the resolution of defects.

• Implementation: Implement managerial functionalities for

reviewing and updating the status of defects.

• Code:

“‘python

def manager_resolve_defect(defect_id, resolution_details,

manager_id):

if has_permission(manager_id, "MANAGE_DEFECTS"): update_

defect_status_in_db(defect_id, "Resolved by Manager", resolution_details) else:

raise AccessDeniedException("User lacks defect manage- ment

permission.")

“‘

Integrate more sophisticated AI models for real-time defect detection using image recognition and sensor data.

Leverage AI to predict future maintenance needs, preventing issues before they occur:

Tailor the DVIR interface and recommendations based on individual user behaviors and preferences.

By adopting AI-driven functionalities, the DVIR system becomes not only a tool for compliance but also a strategic asset in fleet management, driving efficiency, safety, and reliability in fleet operations.

The integration of Artificial Intelligence (AI) into the Digital Vehicle Inspection Report (DVIR) system represents a transformative approach in fleet management and vehicle inspection processes. This conclusion re-emphasizes the benefits, implications, and future potential of this AI-enhanced system.

• By automating and optimizing various aspects of the DVIR process, the system significantly reduces the time and effort required for inspections, allowing fleet managers and drivers to focus on more critical tasks.

• AI’s predictive capabilities enable early detection of potential issues, facilitating proactive maintenance, reducing unexpected breakdowns, and minimizing vehicle downtime.

• The system’s ability to adhere to and automate compliancerelated aspects ensures that fleet operations stay within regulatory boundaries, reducing the risk of violations and penalties.

• With AI-driven insights and real-time data analysis, fleet managers are equipped with actionable information to make informed decisions regarding asset utilization, maintenance scheduling, and overall fleet operations.

• The adoption of this AI-enhanced DVIR system marks a

shift towards data-driven and intelligent fleet management.

• It signifies a move away from reactive maintenance strategies

to more predictive and preventive approaches.

• The system’s ability to adapt to individual asset needs and

user behaviors presents a personalized approach to fleet

management.

• Ongoing advancements in AI and machine learning promise even more sophisticated analysis and predictive capabilities, further enhancing the DVIR system.

• Potential integration with IoT, telematics, and advanced sensor technology could provide deeper insights into asset health and operational efficiency

The system’s design allows for scalability and adaptability, making it suitable for diverse fleet sizes and types, including potential applications in other transportation sectors.

Continued refinement of the user interface, driven by user feedback and AI analytics, will make the system even more intuitive and user-friendly.

Incorporating AI into the DVIR system is not just an upgrade in technology; it’s a strategic enhancement that propels fleet management into a new era of efficiency, reliability and intelligence. As this technology evolves, it will continue to reshape how fleet operations are conducted, setting new standards in vehicle maintenance, safety, and operational excellence [1-3].