Author(s): <p>Taiwo O. Asonja* and Taiwo Alare</p>

The objective of the research was to develop a furniture set that consists of a multifunctional bed, study table and a cabinet. A room at Adeniyi hostel of Federal University of Technology, Akure, Nigeria was used as case study. A pre-study was performed to define the problem area and to set the requirements for the furniture. The pre-study included: studies and discussions with students, literature review within the field, user survey, market search and ergonomics study. When the specification was set and clarified, the concept generation phase was started. Design methods were used to structure and support the design activity. In addition, principles of inclusive design were followed in order to end up with a design that would fit a larger part of the targeted customer group. The generated design concepts were assessed according to fulfillment of set requirements. One final concept was chosen for further development in the following detail design phase. This activity included specifying the design in detail, e.g. related to materials, colors and accessories. The collaboration with the supervisor was essential during the whole project for getting inspiration, feedback and important inputs to the design activity. Hence, the supervisor’s opinion was continuously considered along the design process. A prototype was made of the final design and tests were performed to assess the design and to get input for further development. The motive behind the research is to improve comfort of a growing population with a minimum cost and optimizing space.

There are many reasons why it is becoming more common to live in small places, also called ‘compact living’, and the following text highlights some of these reasons. Some years ago, to live in a big house indicated that one was rich, while to live in a small house signaled a lack of resources. However, this is very different today. Due to the pace of life, many people prefer to live in a small apartment where there is less housework and more time to enjoy life [1]. Likewise, most countries with dense population always faced with issue of housing and usable land. Most people living in these countries live in small apartments because cost of housing kept increasing due to fast raising population and a fixed land area. Most people living in a small apartments especially a room apartments known as ‘bed seater’ in Nigeria find it difficult to arrange the house and live comfortably because a room serve as living room and bedroom synchronously. Small apartments will continue to be the only option for densely populated countries in the future. Therefore the ergonomics of small apartments should put into consideration in order to make it comfortable and economical.

The desire or necessity to live in city centers due to the availability of cultural life and services, or to the proximity of the workplace, is leading many people to live in city centers. Security and public transportation are also typically more developed [2]. This migration make city center densely populated. As persons who have recently lived in Lagos, Nigeria, we can attest to the fact that a significant number of young fellow human beings are willing to pay an exorbitant amount each month in exchange for the use of a four-walled brick-and-mortar living space that could, by many American’s standards be mistaken for a medium sized closet. Trying our best to live functionally in small spaces is simply part of urban living nowadays. It’s pretty simple: There are lots of people, and not a lot of space – meaning that sometimes, whether due to availability or affordability, we squeeze our lives into small apartments. No entryway, no separators, bad Lighting, no tables/ workspace, no bedside storage, not enough Closets and not enough storage units are the major problems of small apartments. This is the finding study in Ikorodu, Lagos, Nigeria as a pre-study to the research.

The need for foldable furniture sets for small bedrooms are assumed to increase in the future since more people (most of all young people) live in small apartments. This project tries to meet this need by the design of a furniture set that offers good comfort and functional features to the user while taking as little space as possible. The overall design, mechanisms and ergonomics are some of the important aspects to consider during the design of such a product.

Comfort, order and cleanliness are very important aspects of living, especially when living in a small flat. For this reason this project wants to reduce problems related to space that small flats usually have by the design of a furniture set that meet the needs while occupying little space. The main objective of this project is to develop a furniture set in which the usable space plays an important role. This furniture set will consist of a bed, a sofa, some shelves and some drawers. The objective is to optimize the use of the space. The other piece of furniture to be developed is a cabinet that also will cover more than one function. These pieces of furniture are aimed to be proper to a large target group, including old and young people, disabled, people of different places around the world with different cultures and capabilities, etc. Hence, the design process will be inspired by the principles of inclusive design, using the Inclusive Design Toolkit (2013).

Bedrooms are not only used for sleeping. Nowadays, bedrooms have more functions. Hence, in small places it is relevant to offer the possibility to, for example, read a book, have breakfast and use the PC. Therefore, these initial objectives were defined:

The project in essence follows a typical designs process as described by Cross [3]. Hence it begins with an exploratory phase (pre-study) for investigating the problem area and define the requirements for the product. This is followed by a concept generation phase to find appropriate design solutions that meet identified requirements. The generated concepts is evaluated in an iterative manner in order to gradually identify the best design solution. The selected conceptual design solution is then further specified in the following detain design phase. All along the design project there is communication with people (potential end users) to get feedbacks on what people want or need. Additionally, the design process follows the principles of Inclusive Design (Inclusive Design Toolkit, 2013) in order to end up with a design solution that will fit a large range of the users in the targeted user group, e.g. related to nationality, ages, sizes, abilities.

That means that the design must not be designed for the average, but rather a range of users. It is very important for designers to also focus on the needs of the people who have more difficulties in their life. This is done by understanding users and their different expectations and needs. In this way the designer can address the problems in order to know the responsibilities of the project.

Inclusive design is not a characteristic of the product; it is a different way to think and work in the design process. The word ‘inclusive’ means that nobody within the targeted population should be excluded. The goal of inclusive design is to make people feel comfortable and equally accepted [4]. The products should be usable and accessible for as many people within the targeted population as possible, leading to reducing needs for a particular design or special adaptation [3]. ‘To create a good design, it is essential to understand the demands and capabilities of the intended users’ [5].

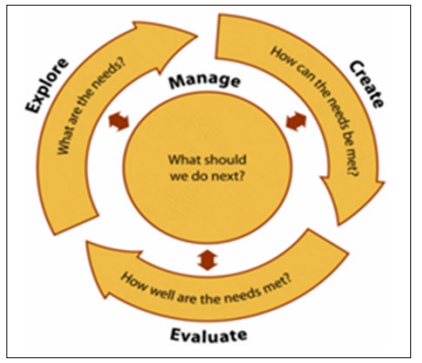

A pre-study was carried out in order to clarify the problem and to set the requirements and functions that should be introduced into the furniture set. This step consisted of exploring and making analyses about the problem and also of looking at what is offered by other companies on the market. Figures 2.1 (Inclusive Design Toolkit, 2013) show the question that should be answered in this paper; what the needs are, always keeping in mind the subsequent steps such as creation and evaluation.

Figure 2.1: Inclusive Design in Three Steps ( www.inclusivedesigntoolkit.com )

These design activities aim to determine what the problem is and what the solutions are. The Inclusive Design approach is focused on (Inclusive Design Toolkit, 2013)

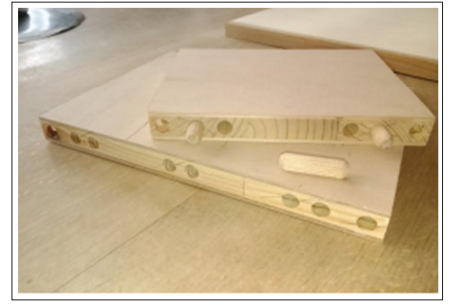

The chosen material to manufacture these pieces of furniture is one called Elder Plywood (Figure 2.2) and described below. In the sector of furniture and doors manufacturing this material is very commonly used. A lot of finishing touches are allowed to this product. Boards of fibers and particles form this Elder Plywood; its two sides are covered with natural or compound wood. The products that are derived of the wood contribute to keep and to improve forests, therefore it helps to the environment care. Another material to be employed is the stitch bond for the beds; this is the cheapest grade of fabric that can ethically be used on a mattress. Any lower grade will probably be sackcloth! It’s rather rough to the touch and used primarily on budget and economy mattresses. It is a printed material; patterns are not woven like damask or any other mattress fabric. Other materials used are: Fasteners, plastic sliding door, foam for beds and nails.

Figure 2.2: Elder Plywood

To Determine the Weight (Wb) of the Bed

Mass of the bed (m) =25.67kg, Acceleration due to gravity (g)

= 9.81m/s²; Wb= mg ~251N

Average weight of Man = 62kg (When converted to Newton

=608N) Weight of the bed frame is approximately 251N

Total Force on the Bed = 608+251= 851N

Area of the bed ‘A’= Length × Breadth (rectangular and edge angle =90°)

Length =1974mm (1.974m); Breadth =1028mm (1.028m) A= 1.974×1.028 =2.0292m²

Stress = Total force / surface area = 851/2.0292 = 419.377N/m² Modulus of Elasticity of Elder plywood =10600MPa or 1.54× 106Psi

E= Tensile stress/ strain To calculate the strain

Strain = Tensile stress/ Young Modulus = 419.77/ 10.6×1010

=0.000000396

Volume = Length × Breadth × Height

Length of furniture set= 1954mm; Height = 1950mm; Width = 1475.85 (When lower bed opens); Width =1039 (When lower bed is closed)

Volume = 1954×1950×1475.85 = 1.954×1.950×1.475 =5.62m³

Bending moment = PL/4 where P is the load and L is the breadth of the bed

Where load P= Wb = 251.8227N

Since this load will be equally distributed on four stands (The rear stands and the gas spring mechanism)

P= 62.955N

Where P is the load acting on each stand and is 62.95N and L which is the width of the bed is 1028mm, therefore the bending moment M will be

M = 62.955×1028/4 =16179.435N-mm

The yield stress of the mild steel serving as support for the bed frame is 200 and the ultimate stress is 0.53

Allowable shear stress = ultimate stress × yield stress = 0.53

×200 =106N/mm³

Sectional modulus Z = Bending moment/ allowable shear stress

= 1619.435/106 =152.63mm³

Shear strain = sectional modulus/ bed volume = 152.63/5.62×106

=0.00002716

Shear angle in the direction of length of bed ∅x = arctan (strain×length of bed/height of bed) = arctan (0.00002716×1954/1950) = 0.00156°

Angle through which the bed opens ‘θ’ = 90°

Torque ‘T’ =F × R × where F is the force and R is the radius (the width of the bed) and θ is the angle of rotation

Force F= 851N; Radius of rotation R =1028mm

T = 851 × 1028 × sin 90° T =874.8KNm

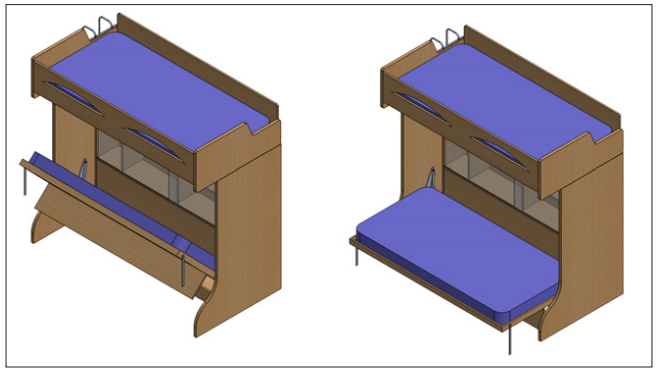

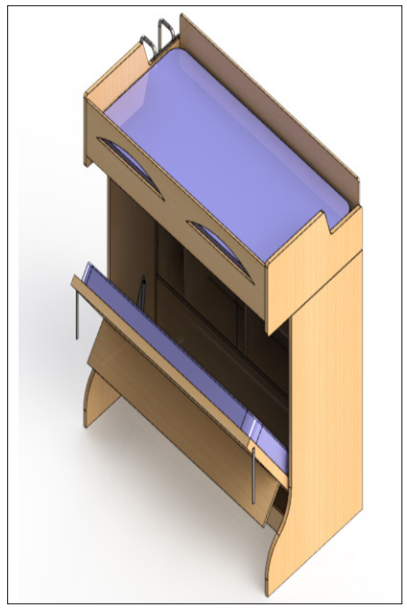

The operation principle of the furniture set is this; the furniture incorporates in itself three components (Study table, cabinet and double bed) the study table is large enough to accommodate both students that will be using the furniture at the same time, it can be hidden when not needed for study and brought out when students need to study, the cabinet having 12 compartments has enough space for storage of reading materials and clothing. The upper bunk bed is permanently fixed and does not transform or become hidden at any time so that if a student needs to study and the other needs to rest, there can be provision for both.

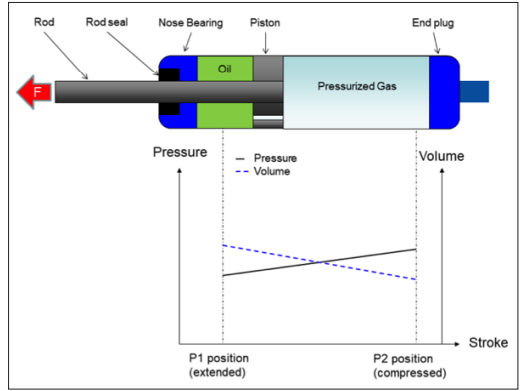

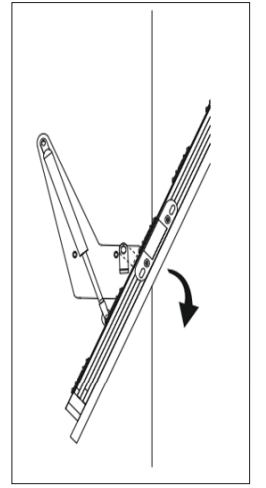

The mechanism adopted for lifting the lower bed to aid its opening and closing is called the gas spring mechanism. A gas spring mechanism is a bit like a super-sturdy version of a bicycle pump, only it is filled with pressurized nitrogen gas (the major constituent of air around us) and oil and completely sealed up so they can’t escape. The gas allows the spring to store energy, while the oil damps (slows and smooth) the movement of the piston and also provides lubrication. Just like in a bicycle pump, there’s a tight- fitting piston mounted on a rod that can slide back and forth inside a cylinder (made from heavy gauge steel, not light plastic as in a bicycle pump).

For the purpose of this design a gas spring to give a force 900N is required and adopted. This is because the average weight of man is 60 to 62kg which is approximately 608, considering the weight of the bed needed to and its component, a total force of 860 to 910N is adopted as standard for choosing the gas spring for this design [6].

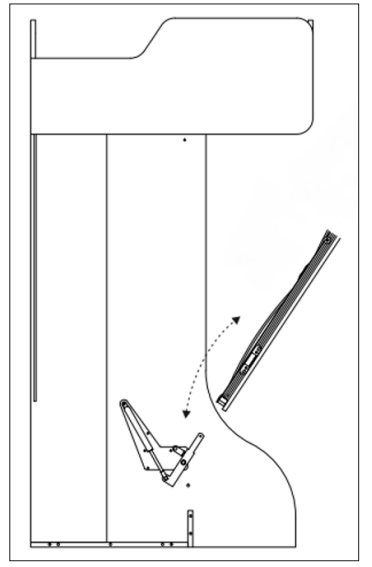

A schematic diagram of the gas spring is shown in the figure below

Figure 2.3: Principle of Operation of Gas Spring

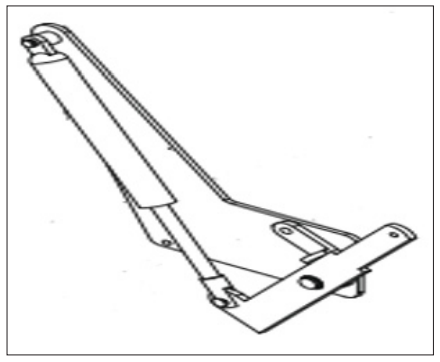

Figure 2.4: Gas Spring Mechanism for Bed support

Figure 2.5: Lower Bed Coupled with the furniture set

Figure 2.6: Gas Spring holding bed in position

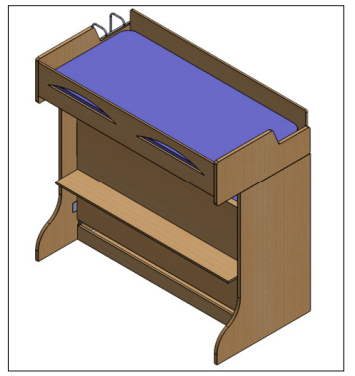

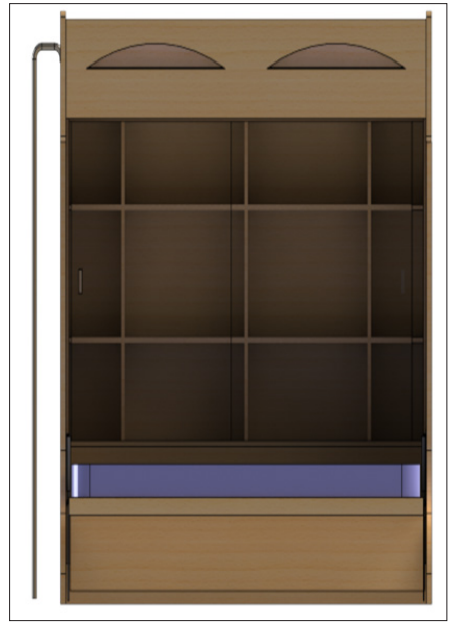

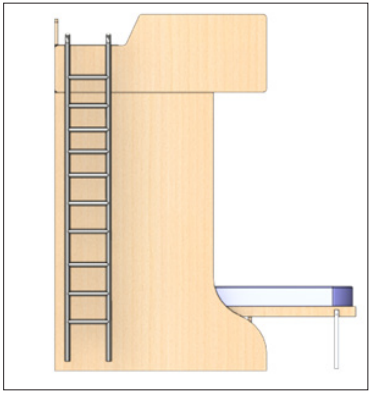

Solid works was used to make the 3D model (Figure 3.1 to 3.3). Different pieces of the furniture were made and later these were assembled. When materials and textures were applied on it, Renders were carried out (Figure 3.5 to 3.8). What took longer was the achievement of more realistic renders. Materials and textures were used, and this was difficult to achieve. During the whole process many ideas had been developed and analyzed. Nevertheless, in this chapter only the final chosen concept is going to be exposed. This piece of furniture consist of three parts; the study table, double bunk bed and cabinet. The Study table measures a length of 1924 millimeters, and a width of 450 millimeters, it is held in place by the lower bunk bed, and also serves as extra support for the bed while it is open, while the bed is closed the table is exposed and can be used for study. The overall dimension of the furniture measures a length 1952 millimeters, and a width 1475 millimeters (with lower bed open), and a height 1950 millimeters, The cabinet measures a length of 1920 millimeters, height of 1582 millimeters, and a width of 280 millimeters, it is composed of 12 compartments of various sizes. The cabinet has two sliding plastic doors to keeps materials kept in it safe and secured. The sliding door can slide all over the front. These doors could also be painted with different colors. Allowance is provided upwards to prevent student sleeping on the bed from having direct contact with the cabinet plastic door while sleeping.

The upper bunk bed with dimensions shown in Table 3.1 is held rigidly in place and aw by the cabinet, and an iron ladder of length equal to that of the entire furniture is attached to it to enable easy accessibility of the bed to student.

Figure 3.1: Showing Furniture Rendering

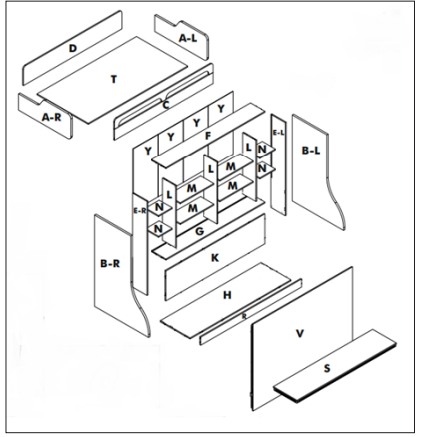

The detailed specification of the various dimensions of the parts including the exploded view of the concept is shown below

|

Track Title |

Piece |

(Inch) |

Millimeters(mm) |

|||||

|

Thickness |

Length |

Width |

piece |

Thickness |

Length |

Width |

||

|

A |

2 |

1.18 |

16.85 |

40.91 |

2 |

30 |

428 |

1039 |

|

B |

2 |

1.18 |

59.92 |

40.91 |

2 |

30 |

1522 |

1039 |

|

C |

1 |

0.17 |

76.93 |

6.69 |

1 |

18 |

1954 |

170 |

|

D |

1 |

0.17 |

76.93 |

12.76 |

1 |

18 |

1954 |

324 |

|

E |

2 |

0.17 |

62.28 |

11.02 |

2 |

18 |

1582 |

280 |

|

F |

1 |

0.17 |

75.59 |

11.02 |

1 |

18 |

1920 |

280 |

|

G |

1 |

0.17 |

75.59 |

10.24 |

1 |

18 |

1920 |

260 |

|

H |

1 |

0.17 |

75.59 |

22.83 |

1 |

18 |

1920 |

580 |

|

K |

1 |

0.17 |

75.59 |

19.76 |

1 |

18 |

1920 |

502 |

|

L |

3 |

0.17 |

41.10 |

10.24 |

3 |

18 |

1044 |

260 |

|

M |

4 |

0.17 |

25.59 |

10.04 |

4 |

18 |

650 |

255 |

|

N |

4 |

0.17 |

11.14 |

10.04 |

4 |

18 |

283 |

255 |

|

R |

1 |

0.17 |

77.01 |

5.31 |

1 |

18 |

1956 |

135 |

|

S |

1 |

0.17 |

75.75 |

17.72 |

1 |

18 |

1924 |

450 |

|

T |

1 |

0.17 |

77.72 |

40.47 |

1 |

18 |

1974 |

1028 |

|

V |

1 |

0.17 |

75.98 |

56.69 |

1 |

18 |

1930 |

1440 |

|

Y |

4 |

0.31 |

62.60 |

19.37 |

4 |

8 |

1590 |

492 |

Figure 3.4: Explode View

In order to achieve more realistic view of the designed furniture and to better understand and comprehend the design concept, Render was applied using Solid works (Figure 3.5 to 3.8)

Figure 3.5: Rendered View Showing Cabinet

Figure 3.6: Side View of Furniture Set

Figure 3.7: Zoomed in View of Gas Spring for Lower Bed

Figure 3.8: Transformation Process of Lower Bed to Reveal Study Table

In the world today, all furniture are designed with the aim of reducing the space occupied in order to fit more components into our homes and hostels because there is generally a problem of over population and not enough space. This furniture set will meet the challenge in student hostels. A transformable space saving furniture has been developed for the use of residences and establishments that have student hostels and a large population of students. The furniture’s capacity is adequate for its purpose. It has proved to be a possible replacement for the conventional bunk beds used in Federal University of Technology Akure hostels.