Author(s): <p>Shashi Raj* and Rajiv Kumar</p>

This study investigates the effects of addition of binding wires on the compressive strength of concrete. Different quantities of binding wires are added to the concrete to find out the optimum quantities of binding wires in which the FRC with binding wires is more effective in terms of strength and crack resistance capacity. Steel fibre reinforcement concrete (SFRC) is a composite material made of hydraulic cements, water, fine and coarse aggregate and dispersion of discontinues small fibre (steel fibre). It is one of the superior crack resisting building materials due to its ability to modify micro and macro cracking by intercepting cracks at their origin and inhibit crack growth. The study found that addition of steel fibre increased compressive strength at 7, 14, 28 days test. SFRC is a superior crack resisting building material due to its ability to modify micro and macro cracking by intercepting cracks at their origin and inhibit crack growth. The results of the study show that the addition of binding wires as fibre can significantly increase the compressive along with the crack arresting capacity. The results also give a detail idea of optimum quantity of steel fibre that can be used in concrete production to get better strength and at the same time it will be more economical.

Concrete is a widely used construction material, and steel bars are used as reinforcement. Fibers can be used to modify the concrete in a more ductile manner. Steel fiber reinforced concrete (SFRC) is a composite material which can be made by adding steel fibers of different form, size and shape in ordinary concrete matrix. Different research articles have shown that the steel fiber gives more strength than glass, polymer and other fibers. This detailed study of fiber reinforced concrete with binding wires is intended to find out if there is an optimum quantity of steel fibre that can be used in concrete production to get better strength and at the same time it will be more economical. The advantages of using fibres as reinforcement have been known since ancient times, e.g. 3500 years. In the early 1900s, asbestos cement was the first widely used manufactured composite. Steel fibre is the most commonly used fibre material, but synthetic fibres are gaining ground. Strain hardening is recognized by an increasing tensile stress after the first cracking, while strain-softening materials exhibit a decreasing tensile stress after the first cracking. This study deals with experimental investigation for M20 grade of concrete to study the compressive strength, and tensile strength of steel fiber reinforced concrete (SFRC) containing fibers of 0% and 0.5% volume fraction of hook end Steel fibers of 50 and 53.85 aspect ratio were used. A result data obtained has been analyzed and compared with a control specimen (0% fiber). A relationship between Compressive strength vs. days was studied to observe the behaviour of steel fiber reinforced concrete for M25 grade having mix proportion of 1:1:2 with 0.44 water cement ratio to study the Compressive strength of steel fiber reinforced concrete (SFRC) containing fibers of 0.5% volume fraction of hook end Steel fibers of 50 aspect ratio were used.

The introduction of the paper should explain the nature of the problem, previous work, purpose, and contribution of the paper. The contents of each section should be provided to understand easily about the paper.

Material specifications are documents that describe the physical, mechanical, and chemical properties of a material or product, as well as the manufacturing processes, testing, and quality control measures required. They are created by engineers, architects, and other technical professionals and are used by manufacturers to produce materials that meet the specifications.

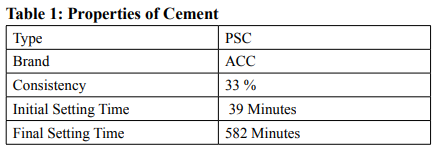

Cement is a binder material used to bind other construction materials together. It is produced by heating raw materials in a kiln at a high temperature, resulting in the formation of clinker. It is used in construction projects and concrete production. For the experimental investigation Portland slag cement is used for making concrete specimens. Table-1 shows the test results which were conducted as per IS: 4031-1988, to find out the properties of cement.

Coarse aggregates are larger pieces of materials added to concrete mixes to provide strength and durability. They are commonly used in construction and landscaping, and their shape, size, and texture can affect the properties of the resulting concrete mix. Crushed angular stone chips of nominal maximum size of 20mm are used and different tests have been conducted as per IS: 383-1970 and IS: 2386-1963. Table-2 shows the observations taken during the tests.

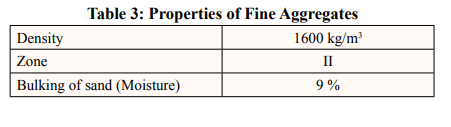

Fine aggregate is a construction material used in the production of concrete and mortar, filling voids between coarse aggregates and contributing to strength and a smooth surface finish. It is also used in other construction applications. Different tests were conducted on natural river sand, which is used as fine aggregate, per IS: 383-1970 and IS: 2386-1963. Properties of sand are shown in Table-3.

Steel fiber is a material made from small, evenly distributed steel filaments that are added to concrete to improve its mechanical properties. It is commonly used in industrial floors, airport pavements, bridge decks, and tunnel linings. It can offer advantages over traditional reinforcement methods, such as rebar, but requires careful consideration of the mix design and placement techniques to ensure optimal performance. Carbon steel Binding wires are cut into pieces and used as fibres in this present study. The detailed properties of binding wires are given in Table-4.

M25 is a mix designation for concrete with a compressive strength of 25 N/mm² after 28 days of curing. The most commonly used nominal mix is 1:1:2, but it is important to conduct trial mixes to determine the actual mix proportions that will result in the desired strength and workability. All the specimens were casted using this nominal mix proportions. As per the nominal mix, the quantities required for 1m³ concrete is shown in Table-5.

Casting and curing of concrete specimens are a common procedure in construction and materials engineering used to create test samples for various physical and mechanical properties analysis. The steps involve the preparation of a mould, mixing and pouring of concrete, curing in a controlled environment, demoulding of the specimen, and testing for various properties. These tests help engineers and construction professionals determine the quality and performance of the concrete in real-life applications.

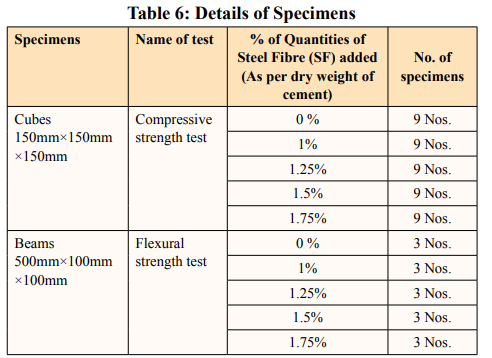

To determine the effects of binding wire as a fire on compressive strength and flexural strength of concrete, cubes of 150mmx150mmx150mm beams of size 500mmx100mmx100mm were casted without fibre and with different quantities of fibre. Hand mixing is used for mixing the concrete without and with fibres to maintain the proper quantities of fibres in each specimen. Specimens were demoulded after 24 hours and cured for 7 days, 14 days and 28 days under normal water.

Moulding specimens is a process of creating a replica or specific shape of an object using a mold or casting material for testing, analysis or preservation.

Demoulding is the process of removing a molded object from the mold after it has undergone the curing or setting stage. It is an important step in the molding process to ensure the object is safely released without any damage.

Curing concrete involves maintaining appropriate moisture and temperature conditions to facilitate hydration, which enhances its strength, durability, and performance. Common curing methods include covering the surface with plastic sheets, using curing compounds, or spraying or ponding water.

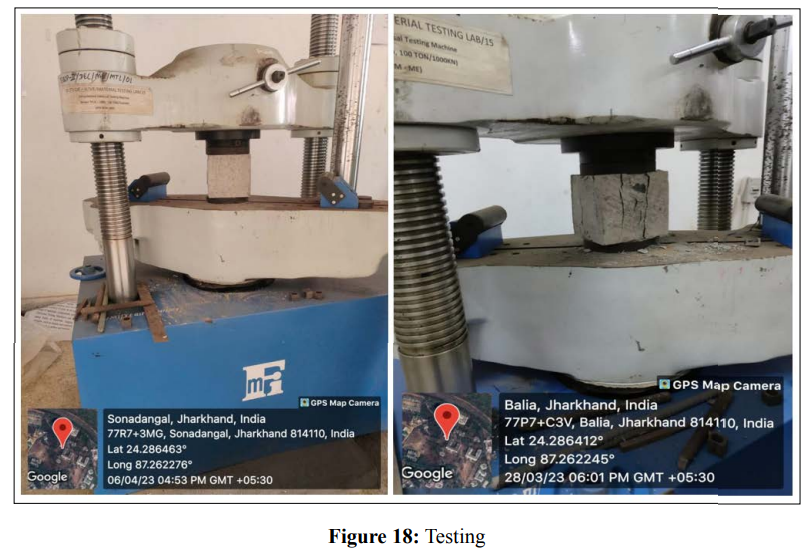

Testing setup involves placing a specimen in a testing machine with two platens between which it is positioned. The compressive strength is calculated by dividing the maximum load at failure by the cross-sectional area of the specimen. Test results are often accompanied by other relevant information, such as age and curing conditions.

The objective of the present study was to find out the effects of addition of binding wires as fibres on concrete. For these two types of tests were conducted, compressive strength test on cubes and flexural strength tests on beams, without and with different quantities of fibres added into the samples while casting.

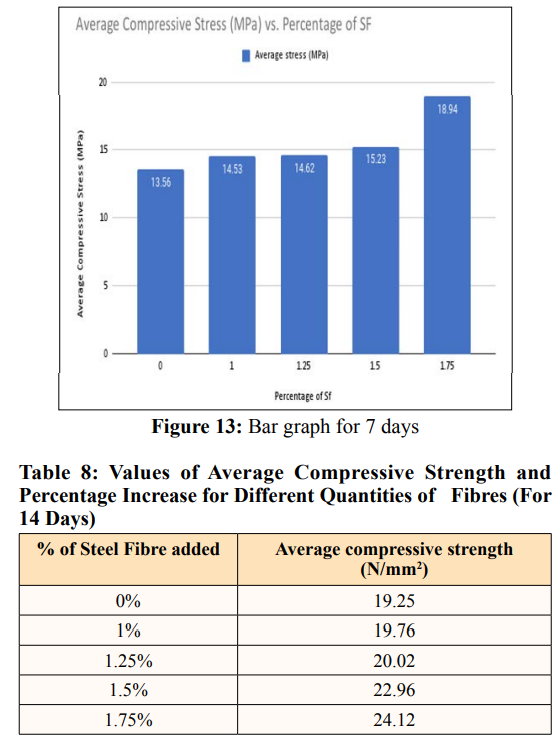

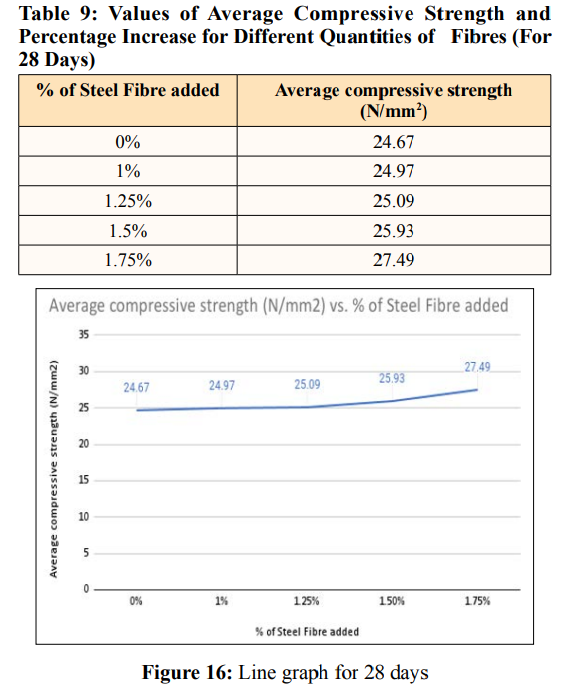

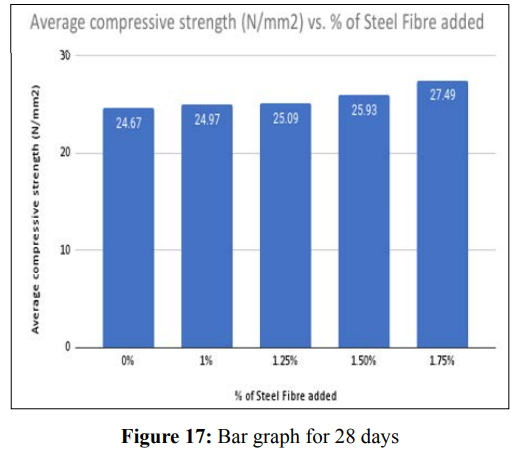

Prepared cube samples without and with fibres are tested after 28 days curing as per IS 516-1959. The test results of Cubes without and with fibres after testing are shown in Table-7, 8, 9. It is shown that the addition of binding wires as fibre significantly increase the compressive strength of concrete. It is also clear that with increase with the quantities of fibres the compressive strength of concrete is increasing.

The study found that addition of binding wires improves the strength characteristics of concrete, increasing compression. It is also clear that addition of binding wires improves ductility and post cracking load carrying capacities. Compressive strength is the important property of concrete that determine its ability to withstand external forces and loads. Compressive strength is the maximum compressive load that a concrete specimen can bear without failure. The result clarifies the compressive behaviour of normal concrete and steel fibre reinforced concrete. We found that the compressive strength of steel fibre reinforced concrete is more than normal concrete as increase in % of SF compressive strength also increases for 28 days. The percentage increase in compressive strength 0%, 1.22%, 1.70%, 5.12%, 11.43% for steel fibre of 0%, 1%, 1.25%, 1.5%, 1.75% respectively. Compressive strength is essential for ensuring the durability and longevity of concrete structures, and should be carefully evaluated during the design and construction phases.