Author(s): Halima S Saeid, Abdelsalam Abuzreda* and Wanisa A gouma

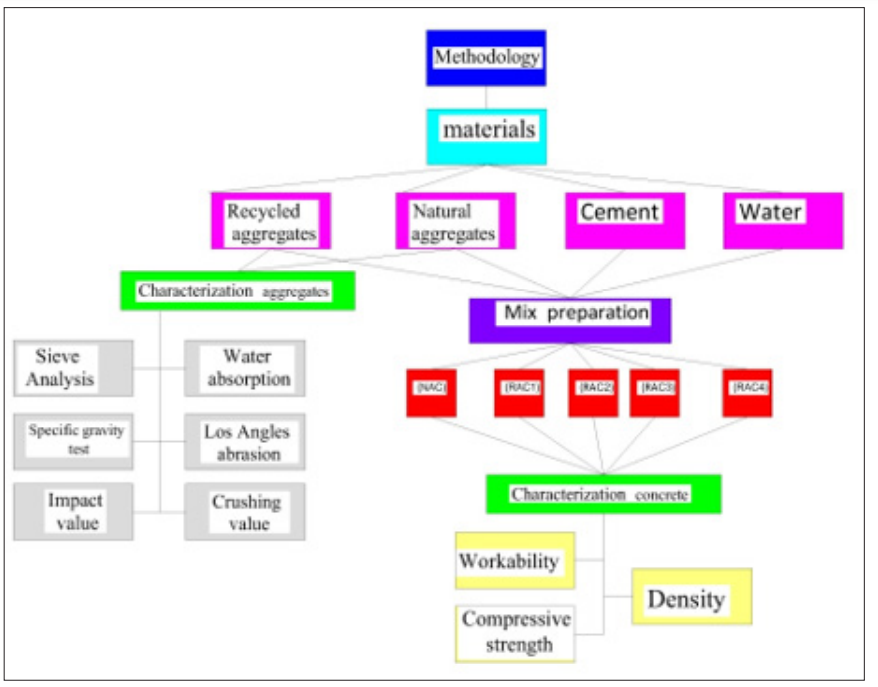

In the last ten years in the city of Benghazi, Libya, it has been observed that the increase in rubble resulting from demolition and construction operations due to wars and destruction operations leads to an increase in this waste, which has become a new challenge to the local environment. Due to environmental reasons and the lack of natural resources, it is very important to recycle construction and demolition waste as much as possible. , Therefore, this study was conducted as a preliminary evaluation of the reuse of concrete aggregates from old and demolished buildings in concrete mixtures. Concrete aggregates were obtained from a building that is more than 20 years old, after crushing the reinforced concrete and sifting the crushed concrete to obtain the granular aggregate needed to make the concrete mixture, according to international specifications. , In this study, the focus was on the use of recycled aggregates in combination with natural aggregates in the concrete industry, and then five percentages of recycled aggregates were adopted ( 0%, 25%, 50%, 75%, 100% ), In this study, a number of tests were conducted on recycled aggregates, and these tests are (sieve analysis, specific gravity, absorption, abrasion, impact value and crushing value. Also, for comparison, the same tests were applied to natural aggregates. , To investigate the possibility of using recycled aggregates in the concrete industry. More than 15 samples of concrete cubes were prepared to conduct concrete tests such as (density and concrete operation for fresh concrete, and compressive strength within 3 days, 7 days, 28 days for hardened concrete) , Accordingly, and through the results obtained, we recommend the use of recycled aggregates in concrete mixtures, provided that it is used in ……. taking into account the necessary specifications in that.

Recycled aggregates are materials that are created from construction and demolition waste, such as concrete, bricks, asphalt, and other debris [1]. These materials are processed, crushed, and refined to create aggregates that can be reused in various construction applications [2]. The construction sector, in addition to being very important for the economy of several countries [3]. Also has a significant impact on the environment as it causes a huge natural resources depletion and generates an enormous amount of waste [4]. Recent wars, that struck our Benghazi city, have caused widespread damage, among which damage to building structures is dominant [5]. Society is not only faced with the problems of fin - ding solutions for the construction, reconstruction and repair of buildings, but also with huge issues concerning disposal of the construction and demolition waste, during the still ongoing cleaning of areas, is being indiscriminately disposed of at municipal waste landfills or often at the so-called illegal dumps [6].

To achieve sustainable issue in construction area, researchers and companies focus on using waste concrete as a new construction material [7]. It is called recycled aggregate which can be produced by concrete crusher. The aggregates are categorized by size as coarse and fine aggregate [8]. If recycled aggregates were practically useful in construction area, two aspects would be expected [9]. One is illustrated at the beginning of introduction, the other one is that we could reduce consumption of natural aggregate resources. Although using recycled aggregates has great opportunity to preserve healthy environment, the properties and characteristics of recycled aggregates has not been fully investigated yet. This paper suggests, to scientific and professional community, a possibility of recycling wasted construction material, primarily concrete, which is mostly used.

Aim: Recycling of building aggregate in concrete mixes.

Table 1 describe main and local sources of the recycled and natural aggregate used in this experiment. and Table 3 describe physical properties of the recycled and natural aggregate used in this experiment.

|

Material |

Source |

|

|

Recycled aggregates |

course aggregates |

Demolished buildings. See Figure (1) |

|

Natural aggregates |

course aggregates |

Al-Abyar area crushers |

|

Fine aggregate |

Shatt al-Badin crushers |

|

Figure 1: Main Post Building Figure 2: Recycled Aggregate.

Figure 3: Classified Crushed Aggregates Grading and Recycled Aggregate

The study area was in the middle of the old city, Omar Al-Mukhtar Street, in Benghazi, where the sample was from a government building, which is the post office building, which was built approximately in the thirties and was developed in the sixties, as it was the only place available for entry. Also, samples were taken from the street because the place had traces of war. The samples were taken randomly in 2018, and the samples were ground manually with a hammer.

five series of concrete specimens with variable amount of coarse recycled aggregate (0%, 25%, 50%,75% and 100%) were prepared. All mixtures used in this investigation were proportioned using British method.

|

Variable |

Slump (cm) |

|

NAC |

17 |

|

RAC1 |

13 |

|

RAC2 |

16 |

|

RAC3 |

18 |

|

RAC4 |

13 |

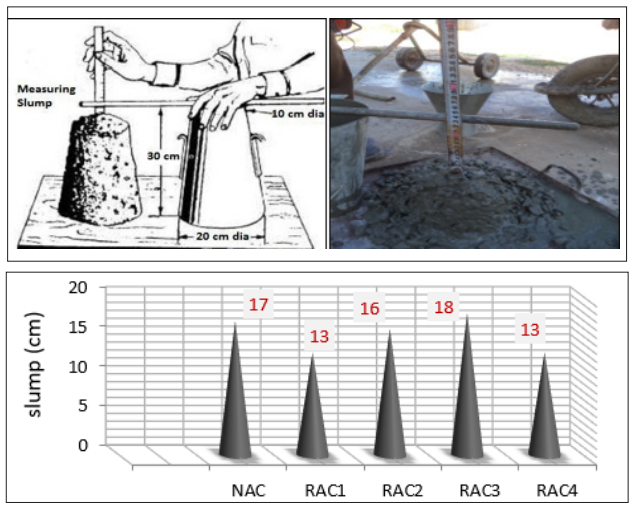

Figure 4: Experimental Work

All the mixes were designed for slump 80-100 mm, and designed for the same air content of 0.015 per unit volume. The same cement was used in all mixes, the variable material is the coarse and fine aggregate type. The proportions used in preparing the various mixes are shown Table (4) to Table (6 ):

|

Variable |

Cement ( Kg) |

Water ( Lt) |

Fine Aggregate ( Kg) |

Coarse Aggregate ( Kg) |

|||

|

Natural |

Recycled |

||||||

|

5/10 |

10/20 |

5/10 |

10/20 |

||||

|

NAC |

325 |

197 |

559 |

303 |

598 |

0 |

0 |

|

RAC1 |

325 |

221 |

559 |

316.6 |

643.8 |

105.8 |

214.9 |

|

RAC2 |

325 |

239 |

630 |

219 |

443 |

206 |

421 |

|

RAC3 |

325 |

252 |

542.6 |

103.9 |

209.8 |

292.9 |

598.8 |

|

RAC4 |

325 |

255 |

529 |

0 |

0 |

349 |

814 |

Table (4)& Table (5) summarizes the physical & Mechanical properties of coarse aggregate. It can be seen from the table that the new recycled coarse aggregate showed lower bulk specific gravity, higher absorption, higher Abrasion value.

|

SIEVE SIZE (mm) |

SIEVE # |

CUMULATIVE RETAINED (g) |

% CUMULATIVE RETAINED |

% SAMPLE PASSING |

|||

|

NCR |

RAC |

NCR |

RAC |

NCR |

RAC |

||

|

31 |

11/2" |

0 |

377 |

0 |

5.38 |

100 |

94.62 |

|

20 |

3/4" |

95 |

3860 |

4.75 |

55.14 |

95.25 |

39.48 |

|

14 |

1/2" |

1268 |

1509 |

63.4 |

21.55 |

31.85 |

17.93 |

|

10 |

3/8" |

584 |

466 |

29.2 |

6.65 |

2.65 |

11.28 |

|

4.75 |

#4 |

42 |

409 |

2.1 |

5.84 |

--- |

5.44 |

|

2.363 |

#8 |

0 |

132 |

0 |

1.88 |

-- |

3.56 |

|

- |

pas |

0 |

238 |

0 |

3.4 |

-- |

-- |

|

Property |

Designation No. |

Symbols and Results |

|

|

NAs |

RCA |

||

|

Bulk dry S.G |

BS812:PART2:1975 |

2.38 |

2.22 |

|

Bulk SSD S.G |

2.44 |

2.36 |

|

|

Apparent S.G |

2.54 |

2.58 |

|

|

Effective S.G |

2.46 |

2.47 |

|

|

Absorption (% Abs.) |

BS812:PART2:1975 |

2.69 |

6.18 |

|

Abrasion value(%A.V) |

ASTM : C131-80 |

48.90% |

52.30% |

|

Impact value, % |

BS812:PART 3:1975 |

25.80% |

32.20% |

|

Crushing value,% |

BS812:PART 3:1975 |

32% |

33% |

|

Property |

Designation No. |

Results |

|

Bulk SSD S.G |

ASTM : C127&C129 |

2.77 |

|

Apparent S.G |

2.75 |

|

|

Absorption (% Abs.) |

0.68 |

The recycled concrete aggregate can influence the properties of fresh concrete due to their greater angularity, surface roughness, absorption, and porosity. The effects of the recycled concrete aggregate on the key fresh properties of concrete, as observed from the available literature [10].

Slump test was conducted to assess the workability of fresh control concrete and concrete containing recycled aggregate. The slump test was carried out according to ASTM C143, for each mix in the test program, a sample of freshly mixed concrete is placed and compacted by rod in a frustum of cone mold as shown in Figure [5,11]. The slump value is equal to vertical distance between the original and displaced position of the center of the top surface of the concrete after raising a mold.

Figure 5: Slump Value Determination

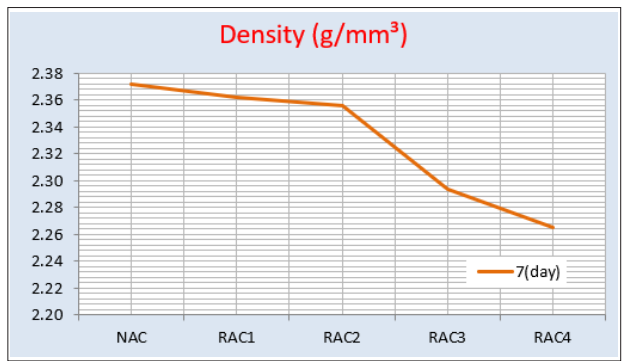

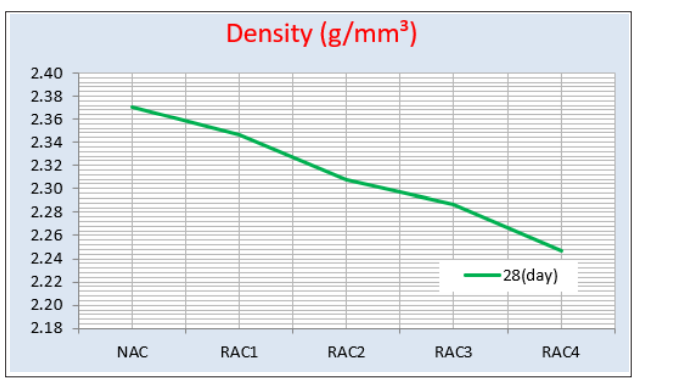

Density In this research, the density of concrete specimens was the theoretical density and it was calculated by dividing the weight of each cube on the cube volume. The same cube specimens which used to determine compressive strength were used to determine the density.

Figure 6: Concrete Density of Cube at 3 Days

Figure 7: Concrete Density of Cube at 7 Days

Figure 8: Concrete Density of Cube at 28 Days

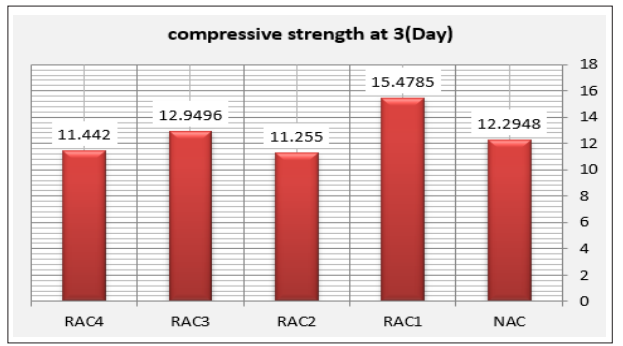

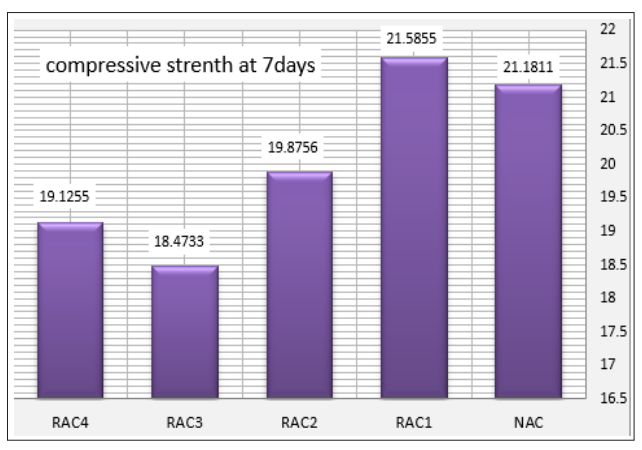

The Compressive strength can be calculated by dividing the max load applied to the area of the cube. The formula for finding the Compressive strength is, C = P/A Where, P = Max load applied on the cube, A = Area of cross section of the cube

|

|

compressive strength of cube ( Mpa) |

||

|

Variable |

3(Day) |

7(Day) |

28(Day) |

|

NAC |

12.2948 |

21.1811 |

28.9473 |

|

RAC1 |

15.4785 |

21.5855 |

29.542 |

|

RAC2 |

11.255 |

19.8756 |

25.05 |

|

RAC3 |

12.9496 |

18.4733 |

25.67 |

|

RAC4 |

11.442 |

19.1255 |

26.559 |

Figure 9: Compressive Strength of Cube at 3 Days

Figure 10: Compressive Strength of Cube at 7 Days

Figure 11: Compressive Strength of Cube at 28 Days

From the experimental work carried out on “Recycle of Concrete Aggregates”, the following conclusion can be drawn: