Author(s): Sabu S*, Mehr AS and Carton JG

The role of electricity is becoming significant in our advancing world. Currently, Ireland’s energy mix heavily relies on carbon-polluting fossil fuels, posing an environmental challenge. As per the Paris Agreement 2015, Ireland is ambitiously targeting to meet net zero carbon dioxide (CO2) emissions by 2050 and a 51% reduction by 2030. The country is shifting towards renewable energy sources to generate power to achieve this target. With abundant wind energy available, Ireland can meet its goal. However, due to the intermittent availability of wind energy, an energy backup for power generation is necessary. The use of curtailed or dedicated wind for producing hydrogen gas through electrolysis, and storing it in underground salt caverns is one approach to the problem. Northern Ireland has a rich source of Permian salt deposits offering a better place to store hydrogen which can be withdrawn for electricity generation, or used as fuel in transportation sectors. The Life Cycle Assessment (LCA) of the hydrogen systems can scrutinise the environmental impact of carbon emissions. This study analyses routes to reduce the environmental impact by evaluating polluting hotspots during the construction and operation phase of the system. This paper compares the impacts of the LCA on a hydrogen system which consists of a wind energy source for hydrogen production through electrolysis, transportation in pipelines and compression before storing it in salt caverns. A comparative analysis is carried out with the LCA of the hydrogen system with an electrical grid supply source. The results show that the impacts contributed by a renewable source are less than the electricity from the grid for the island of Ireland

The Republic of Ireland is an island with a thriving economy in the European Union. Oil, gas, electricity, renewable energy sources, coal, peat, and non-renewable waste all serve as energy sources in the current mix. Fossil fuels like oil and gas are becoming more insecure and expensive [1]. An alternative is a renewable energy system which is efficient, environment friendly and sustainable. Ireland has encouraged renewable sources to satisfy its needs. The Sustainable Energy Authority Ireland (SEAI) report 2021 summarises Ireland's current renewable energy sources as hydro, wind, biomass, renewable waste, landfill gas, biogas, and solar PV. In 2020, wind energy accounted for 86% of renewable electricity [2]. As renewable energy increases the need to manage and store energy to secure access to a consistent, dependable, and economical energy supply becomes more pressing.

Renewable energy can be stored as gaseous hydrogen which also acts as an energy vector [3]. The energy from a renewable source can be used to produce green hydrogen. For storing hydrogen on a large scale for a longer period, the underground storage option is the best choice among the existing large-scale hydrogen storage systems [4]. The Islandmagee site in Northern Ireland has been identified as suitable for salt cavern storage. Thus, developing a hypothetical hydrogen energy system by consuming renewable energy from wind energy to produce green hydrogen and securely storing it in the cavern after compression is proposed.

The Life Cycle Assessment (LCA) study of the whole system can give insights into the greenhouse gas emission for each subsystem throughout construction and operation in the hydrogen production till storage. The impact categories look into the seriously affected areas and can take alternative steps to lessen the contributing and dominating factors. To have a better comprehension of the analysis, the whole system is compared with a hydrogen system sourced from the electrical grid supply in Ireland. The data have been acquired by comparing various studies carried out by previous researchers on wind turbines, electrolysers, pipelines, compressors and salt caverns. Specific calculations and site conditions are considered to increase the data’s accuracy. Thus, the life cycle assessment of this hypothetical system from cradle to gate and gate to gate is conducted. The analysis provides a comprehensive understanding of environmental emissions. Consequently, the findings demonstrate that wind energy has a lower environmental impact than electricity supplied from the grid. Several recommendations are proposed for future research to enhance data accuracy and further investigation in the subject.

The exploitation of fossil fuels is immense, with the increasing global population and demand for living standards by developing countries [5]. In a country like Ireland, which has limited fossil fuels to extract for its own needs, it must ultimately rely on imported energy. In the 21st century, security concerning the oil supply is a limited and finite resource, primarily due to ongoing conflicts and wars between countries. When the supply diminishes,the prices of the fuels begin to rise in uncertainty as the nation cannot meet its need resulting in economic inflation. Moreover, the emissions caused by them are devastating across the world, causing global challenges like global warming and severe threats to human health and environmental life. Moreover, aiming to "Hold the increase in the global average temperature to well below 2°C above pre-industrial levels and pursuing efforts to limit the temperature increase to 1.5°C above pre-industrial levels, recognising that this would significantly reduce the risks and impacts of climate change," the 2015 Paris Agreement on climate change, signed by 195 countries, sought to address the issue of global warming and its effects [6]. An alternative to this inevitable source is an efficient, environment friendly and sustainable renewable energy system. Hence, the EU & Irish government and energy agencies are looking at alternative energy sources to sustain the energy supply.

The transition from the fossil fuels era can be done by cleaner energy sources, renewable energy, which are promising and causes minimal impacts to the environment. Renewable energy ensures energy security within the country. Each country has its own abundant availability of natural resources. Ireland has also increased its dependence on renewable energy to satisfy its energy needs [7]. Among the renewable sources, wind energy has the largest contribution to gross final consumption according to Sustainable Energy Authority of Ireland's report in 2021. On the island of Ireland, nearly 400 wind farms are installed in onshore and offshore with energy capacity of 5,585MW as per the data in 2022. The contribution of wind energy was about 9,780,830 MWh from the total electricity production of about 34,506,210 MWh in 2022. Thus, it can be considered as the most economical and largest renewable electricity resource in the island of Ireland. Since it is a natural resource, the consistency of the energy cannot be explicitly predicted as it varies according to the weather conditions. The number of resources (wind) available in a given year influences generation output. It is also influenced by the degree of plant outages caused by problems, maintenance, and curtailment. In Ireland, some excess energy is stored in Lithium-Ion batteries from the grid to secure the demand-supply. Thus, a bulk energy storage system is needed to keep the extra energy as a buffer and meet demand as renewable electricity continuously fluctuates [7].

Hydrogen is gaining popularity as a long-term storage option for surplus electricity with the increased power generation from different renewable sources. Hydrogen is termed as the future green energy carrier. It has been proved that it is the clean, light, and most highly flammable fuel on combustion producing water. The primary energy source used for hydrogen production determines the environmental creditionals or “colour” of hydrogen. Green production technology is regarded as almost economical but with the best environmental creditionals, when renewable energy sources produce hydrogen through electrolysis. Hydrogen can thus be produced through an electrolysis process which converts water into hydrogen and oxygen using electricity. Alkaline water electrolysis (AEM) is the most mature technology among all the electrolysis methods available today. This technology has minimal operating expenses and long operational life [8]. The underground water resource will meet the water source for hydrogen production through borewells. Since the water for the electrolysis should be clean and filtered, a reverse osmosis process is carried out for the water in the borewell to the electrolyser. Hydrogen produced can be transported in various forms such as compressed gas, liquid or ammonia. It can be easily converted to liquid form to transport in trucks or ships or it can also be transported in pipelines in compressed gaseous state. The compressed hydrogen at a pressure of 50 to 100 bar can be transported easily through pipes. The environmental impact caused by the trucks will be much higher than that of pipelines [9].

Since hydrogen has a larger energy content per unit mass and lower energy volume than other gases, underground storage is a proven method to store significant energy (electricity) after converting it into hydrogen [10]. Depleted gas/oil reservoirs, aquifers, and salt caverns are the three main categories of underground gas storage. The salt caverns are a viable choice for hydrogen storage because to certain geological features such as tightness, excellent mechanical properties of salt, and its resistance to chemical reactions. Furthermore, the viscoelastic properties of evaporitic rocks aid in their improved sealing function. Because the salt caverns are mechanically stable, the procedure (injection- withdrawal) is adaptive and ideal for medium and short-term storage [11]. Permian salt layer deposits provide an excellent opportunity to construct salt caverns in the Larne lough, Northern Ireland and a good option for large-scale gas storage and supply [12].

A life cycle assessment (LCA) assesses the environmental characteristics of a product system from raw material procurement through ultimate disposal. This life cycle includes the production of electricity from the wind turbines to produce green hydrogen using water electrolysis and the transportation and compression of produced hydrogen to store in salt caverns and the comparative model with energy source from the grid supply. The models are created and implemented in specialised software tools to aid in producing LCA studies [13]. This research is carried out in a LCA tool - GaBi software. The availability of datasets, flexibility, and quickness in assessing the outcomes for Life Cycle Inventory (LCI) makes to choose this for the proposed work.

In the year 2014, Ormazabul conducted a study on the comparison of LCA software [14]. Among the 20 software, in terms of database, reporting and uncertainty analysis, SimaPro and GaBi were concluded as the commercial software in the market. An ex- ante life cycle assessment of hydrogen production in Netherlands was conducted by Delpierre and his colleagues in the year 2018 [8]. In the study, they analysed the two types of electrolysis method AEM and PEM technology for the present year (2019) and for the future (2050) through wind energy. The results interpreted that electricity is the largest contributor even after consumption of renewable energy and there is no much variation within both technologies for the environmental impact. Ghandehariun in his LCA study of the wind-based hydrogen production in Western Canada selected a particular wind energy farm in Alberta to produce hydrogen through alkaline electrolyser [15]. This hydrogen is later compressed and transported in pipelines to the industry for bitumen upgrading. The significant contribution is seen in the manufacturing and installation stages of the equipment.

From the literature carried out by previous researches, the whole system analysis of hydrogen generation to storage has yet to be carried out as the salt cavern construction themselves can significantly contribute to environmental pollution. Moreover, to date there has yet to be an existing study on the life cycle assessment of hydrogen storage on a large scale from its root of generation. This research assesses the life cycle assessment of a hypothetical hydrogen storage system that can meet the energy need of the Island of Ireland. In a sustainable progressive environment, this project’s LCA assessment will aid future research.

The research is carried out for a system of green hydrogen production from an onshore wind farm in Ballymena, Northern Ireland, with a production capacity of 21.3MW. This electrical energy produces hydrogen through an alkaline electrolyser. The green hydrogen is then transported to the underground storage site in Larne, Northern Ireland, through a polypropylene pipeline network. The hydrogen is injected into the salt caverns after compression at 250 bar pressure. The overall volume of hydrogen stored in the salt cavern at Larne will be 3,360,000 m3 [16].

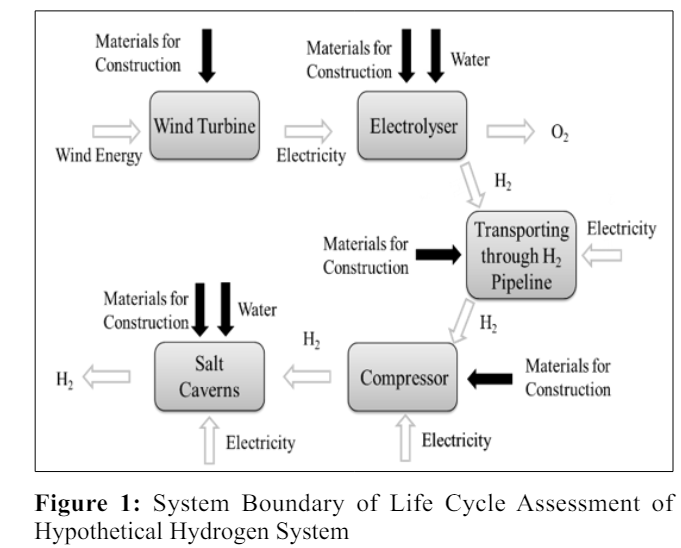

The aim is to compare the life cycle assessment (LCA) of the hydrogen production system from wind turbine to large scale storage in salt caverns with the hydrogen system from the electrical grid supply. The scope of the LCA involves the production to operation which is cradle to gate and gate to gate process. The functional unit for the LCA of the whole system is taken as 1kg of hydrogen stored in the salt cavern. The system boundary for the LCA approach is given in the Figure 1.

The whole system consists of a wind farm, an electrolyser, a pipeline for transportation, a compressor and underground salt cavern storage system. The selected wind farm for the case study is the Rathsherry wind farm, with an installed capacity of 21.15MW, in Ballymena in the county Antrim, Northern Ireland. The region has rich source of wind potential annually with an average speed of 6.21m/s. It consists of 9 Enercon 2.3MW E82 model wind turbines with the capacity of each turbine as 2.3MW. Due to inefficiency in the data, the inbuilt database of the electricity from the wind power in the software is used.

The alkaline electrolyser being the most matured and commonly used for the hydrogen production, produces the green hydrogen to serve as the energy carrier for storage. The available data of an AEM with 50kW power rating is chosen for producing 1kg of hydrogen for the model [17]. This process in the model is fixed by scaled to 1 which automatically normalise all the inflows and processes connected in the system.

The green hydrogen is transported to the salt cavern in the Islandmagee Site in Larne, County Antrim, Northern Ireland through pipelines. The distance from the production site to the storage site is around 50 to 57 km. The pipeline size is assumed to be 0.6m (600mm) to transport hydrogen over a distance of 50 to 55km as per the reliable data collected from Gas Network Ireland [18]. The material of the pipeline is selected as polyethylene as it has less impact over than other materials.

A 250-bar pressure compressor is utilised to compress the hydrogen gas to inject into the salt caverns. The available material data for compressor is built with reference of a 60 bar pressure compressor from the article of Ghandehariun S. for life cycle assessment of wind-based hydrogen production in Western Canada [15].

The salt caverns, in Larne, is capable of storing hydrogen up to1.2TWh with 7 caverns. Seven caverns are 80m in diameter and 160m in height and are located 1500 meters below Larne Lough. The caverns are constructed through the leaching process which enables the hydrogen to be stored in it with the help of the cushion gas. The volume of each cavern is 600,000 m3 with 480,000 m3 of working gas and 38,000 m3 of cushion gas [19]. The production rate of the cavern with the leaching is 100m3/h for the maximum leaching flow rate of 300m3/h. Then, the gas is stored in each cavern in the site and taken out in the demanding times.

So far, a number of LCA have been carried out for wind turbines, electrolyser, compressor, pipelines and storage systems. When it comes to the data acquisition of each component in the hydrogen storage system, the technical specifications should resemble to the data availability and previous studies on LCA. When the data is precisely matching to the required, some tolerances are done inputted into the software. If the data values are far different from the required, the inputted data will be scaled to the number of requirements. There is no exact study on the LCA of the hydrogen system from its production to storage in salt caverns.

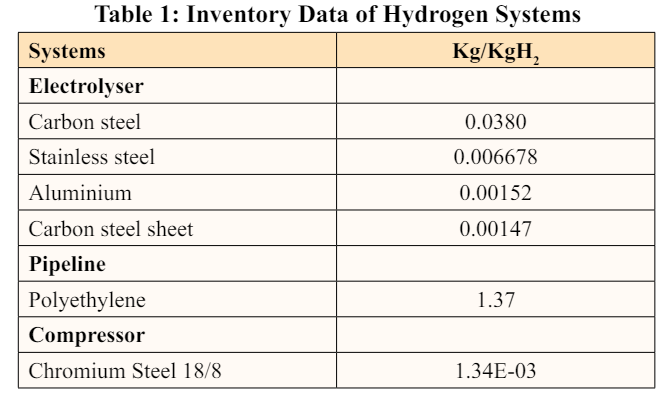

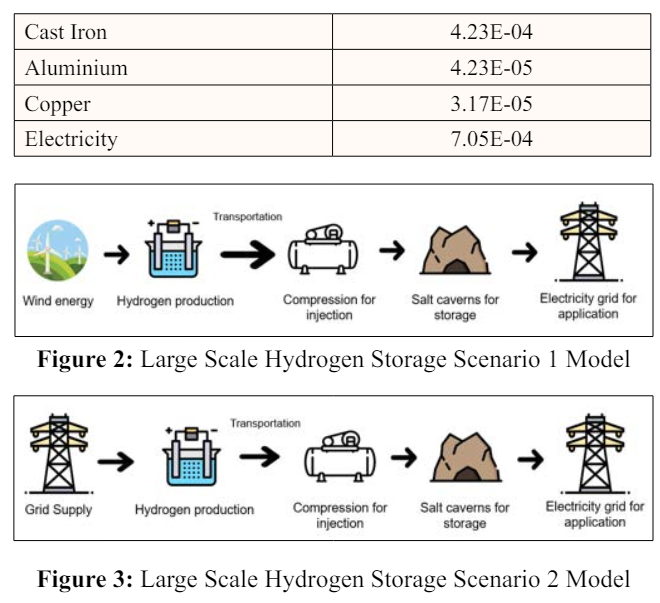

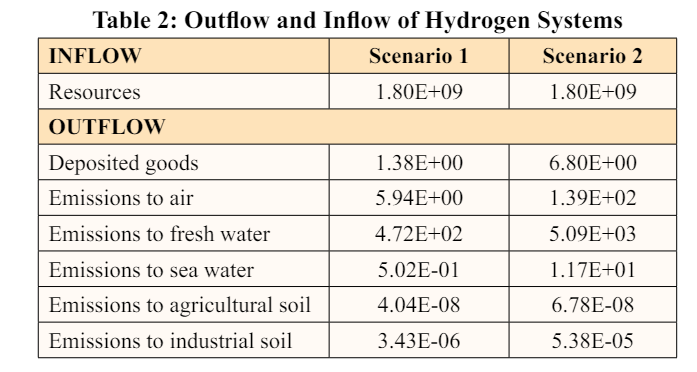

While gathering the data, some of the raw materials to the flow will be ultimately having low impact to the environment compared to the total. The 1% rule in the life cycle assessment helps to exclude the materials having lower contributions, which accounts to less than 1% of the impacts which is applied in this case study. The inventory data (LCI) of the models which are developed from the previous studies are provided in Table 1. Two Gabi LCA models are developed as scenario 1 (Figure 2) and scenario 2 (Figure 3) which are hydrogen system powered by wind and electrical grid supply respectively. The analysis has been carried out comparing the results of both scenarios.

The life cycle environmental performance is characterised by quantifying the environmental impacts of Global Warming Potential 100-year horizon (GWP), Ecotoxicity Potential (ETP) and Acidification Potential (AP), developed by CML 2001 - JAN 2016. These life cycle impact indicators are chosen based on their significance in energy systems that incorporate hydrogen production [20]. As detailed earlier, the assessment for two phases is considered, one with the electricity source from wind power (Scenario 1) and the other with electricity from the grid (Scenario 2). From the results, it is visible that scenario 1 has less impact compared to scenario 2. The hydrogen systems’ overall inflow and outflow are detailed in the Table 2. Interpretation of the results signifies that most emissions to air, fresh water, sea water, agricultural soil, industrial soil and deposited elements impacting the environment in directed from the scenario 2 than scenario 1.

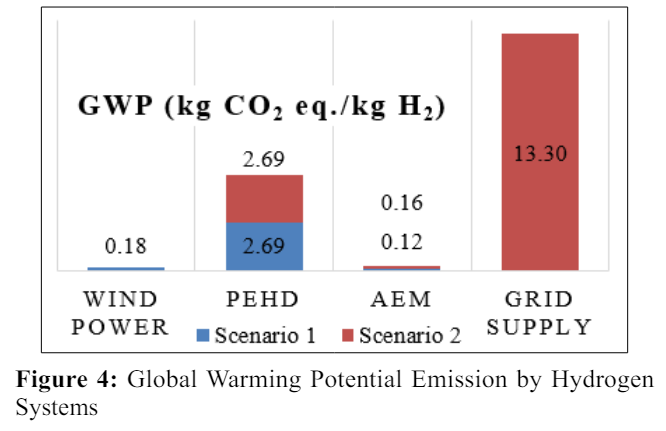

The most impacting process in the hydrogen system can be identified through the dominance analysis. The Figure 4 depicts the Global Warming Potential (GWP in kg CO2 eq./kg H2) in hydrogen systems mainly, electricity from wind power, polyethelene granules (PEHD) for pipeline production, alkaline electrolyser (AEM) production and electricity from the grid of scenario 1 and 2. It is clearly visible that the electricity from the grid in scenario 2 has the greater emission with the quantity of 13.30 kg of CO2 eq. per kg of H2. Meanwhile, the CO2 emission in the AEM production from the scenario 1, followed by scenario 2 is least quantified with the other processes.

The wind energy source in the scenario 1 emits only 0.18kg of CO2 eq. per kg of H2 which can be regarded as a negligable value while comparing with the emission from grid supply. The intermediate process, PEHD for the pipeline in transportation for both scenarios, has mediate effect in the GWP emission. Therefore, the emissions from electricity grid can be reduced in the system if it is replaced with a renewable energy source.

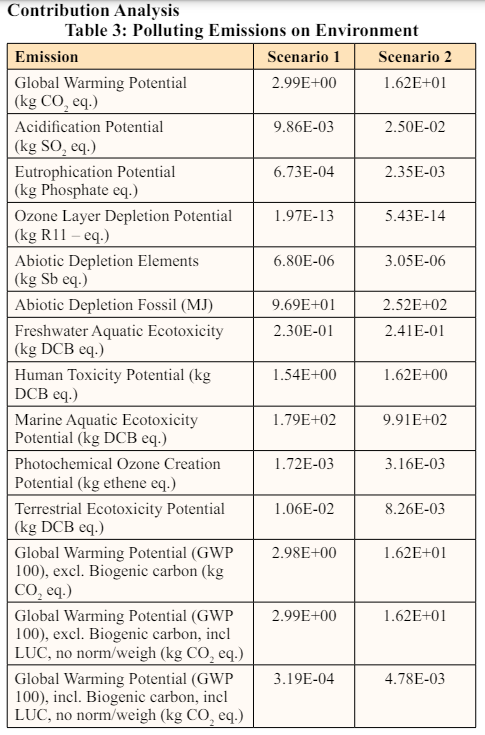

The contribution analysis helps to analyse the results of the life cycle of hydrogen system by evaluating the contribution of polluting elements into the surroundings. In Table 3, the global warming potential emitted by scenario 1 and scenario 2 are detailed. The results states that scenario 2 (16.2 kg CO2 eq.) has more carbon dioxide (CO2) emission than that of the Scenario 1 (2.99 kg CO2 eq.). The marine aquatic ecotoxicity emission in the scenario 2 has the largest contribution to the environment with a value of 991 kg DCB eq. per kg of H2. The consumption of electricity grid is the possible reason for the significant impact in the marine aquatic ecotoxicity. Meanwhile, a least notable contribution is observed in the sulphur oxide (SO2), phosphate, and ethene emission. The contributions of R11 and Sb are literally less than the numerical values.

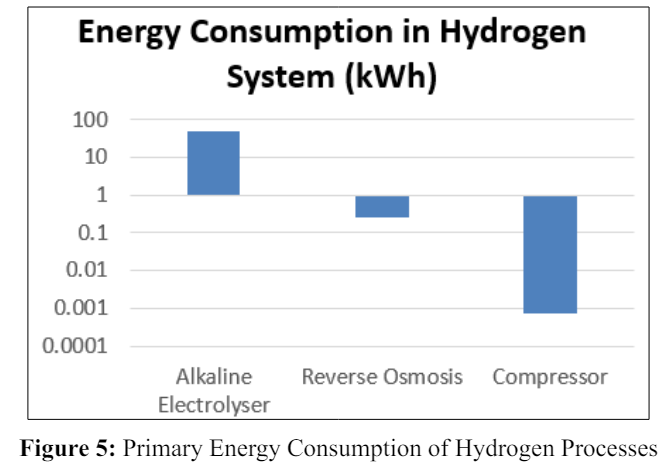

This analyses the amount of consumption of primary energy in the hydrogen system. The alkaline electrolyser for the hydrogen production process, reverse osmosis for the water purification and compressor for compression of hydrogen gas involves the primary energy consumption. Some of the other processes, which also consumes electricity, are negligible (under 1% rule). The energy consumed by each process in both the scenarios are resulted to be same. The highest consumption of electricity is observed in the alkaline electrolyser by consuming 50kWh/kgH2. Whereas, the compressor has the least consumption (0.000705kWh/kgH2) among the processes. The reverse osmosis consumes 0.252kWh/ kgH2. Figure 5 gives the overview of the energy consumption in each process of the hydrogen system.

The study conducted the comprehensive life cycle assessment of hydrogen system from its production to storage powered by wind energy in Ireland to which a comparative analysis was performed with a similar system powered by electricity from the grid. The results unequivocally demonstrate that the wind-powered hydrogen system exhibits significantly lower environmental impacts when compared to the grid supply-based alternative. This finding underscores the environmental superiority of renewable energy-driven hydrogen production over conventional grid electricity sources. As the world increasingly seeks sustainable and clean energy solutions, this study provides valuable insights into the benefits of utilizing wind energy for green hydrogen production. The choice of polyethylene material for the pipeline and the utilization of salt caverns for hydrogen storage contribute to minimizing the systems’ overall environmental footprint. It is essential to continue exploring advancements in renewable energy technologies, hydrogen production processes, and storage methodologies to further improve the efficiency and environmental performance of such systems. Collecting more accurate and comprehensive data to enhance the robustness of life cycle assessments for similar hydrogen systems. Implementing wind- powered hydrogen systems can play a pivotal role in mitigating climate change and fostering a greener and more sustainable future fore Ireland and beyond.

The results of the life cycle assessment of hydrogen storage of the wind turbine carried out could be concluded as precise. As the exact values of the wind turbine source is not used for the analysis, instead, the existing database in the software on the primary wind energy in Ireland is adopted. To improve the accuracy of the results, it is suggested to potentially use more exact values of the wind turbine model and the wind farm site conditions. In addition a future study could benefit if more precise data for the hydrogen transportation system which has a significant energy consumption and the leaching process to construct salt caverns in the hydrogen storage system could be sourced. In addition a comparative analysis of the hydrogen system can be completed with solar powered sources or other renewable energy sources for further study and assessment.